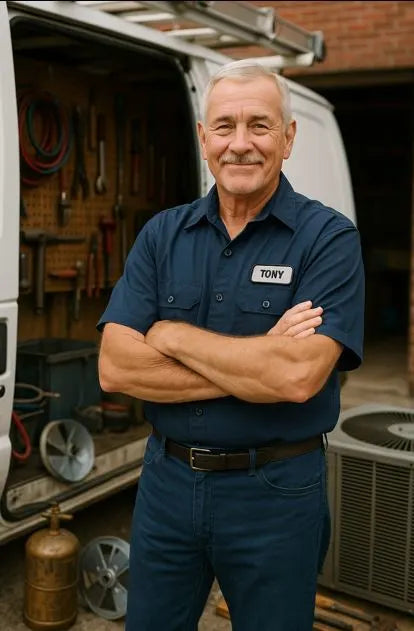

Installing a Through-the-Wall AC: What Really Happens When Tony Cuts a Hole in Your Wall

Installing a through-the-wall AC isn’t a “cut a rectangle and shove it in” project.

Homeowners who try it that way end up with:

-

crooked units

-

airflow problems

-

mold inside the wall

-

water leaks

-

outdoor noise blasting into the room

-

ruined drywall

-

sleeves that don’t drain

-

units that burn out early

Tony has installed hundreds of wall units in every type of home imaginable — brick, stucco, vinyl, plaster, foam siding, you name it. He knows exactly what can go wrong and exactly what needs to happen for a clean, tight, efficient install.

This is Tony’s full, real-world walkthrough of installation day — the step-by-step process from the moment the tools come out to the moment your room immediately feels colder.

Let’s get started.

1. The First 20 Minutes: Measurements, Level Checks & Breaker Location

A wall AC installation begins inside, not outside. Tony measures and checks EVERYTHING because once the saw hits the wall, there’s no going back.

What Tony checks:

-

exact wall thickness

-

stud locations (critical!)

-

electrical path

-

interior clearance

-

sleeve depth requirements

-

leveling

-

existing outlet location

-

insulation inside the cavity

-

exterior façade: brick, siding, block, stucco

A bad measurement leads to:

-

off-center units

-

structural cuts

-

crooked sleeves

-

airflow problems

-

sleepless nights

Tony never cuts until he’s mapped the entire opening — twice.

(Reference: Residential HVAC Load Calculation Standards)

2. Cutting the Hole: The Part Homeowners Fear — and Rightfully So

This is the moment you hear the saw.

This is also the moment where DIY installs go horribly wrong.

Tony cuts the wall in stages:

-

Interior drywall cut — using a level to ensure a perfect rectangle

-

Insulation removal — checking for wires, plumbing, or unexpected surprises

-

Exterior cut — aligned to the interior, clean through siding/brick

-

Cavity inspection — checking moisture, airflow gaps, framing

This isn’t a single cut.

This is surgical work.

Worst case Tony has seen:

Someone cut a load-bearing stud clean through and had to bring in a framing crew.

Don’t be that person.

3. Setting the Sleeve: The Most Important Step of the Entire Job

Most homeowners think the AC unit is the star of the show.

It’s not — the wall sleeve is.

The sleeve controls:

-

drainage

-

airflow direction

-

structural support

-

sound isolation

-

weather resistance

Tony’s Sleeve Requirements:

✔ perfectly level side to side

✔ slight downward slope toward the outside (¼ inch)

✔ no inward slope EVER

✔ sealed corners

✔ insulated walls

✔ correct depth so unit doesn’t suffocate

✔ solid anchoring to framing

A bad sleeve means:

-

water pooling

-

leaks

-

mold

-

noise

-

reduced cooling

-

shortened lifespan

(Reference: Home Insulation and Envelope Performance Manual)

Tony has ripped out dozens of sleeves that were installed at the wrong angle — and the homeowner always thought the AC was the problem.

4. Sealing & Insulating the Sleeve: The Difference Between a Quiet Unit and a Noisy One

Tony seals every gap, inside and out.

Not with cheap foam. Not with duct tape.

With high-quality HVAC-grade materials.

Why sealing matters:

-

stops outside air infiltration

-

prevents insects

-

reduces noise

-

boosts efficiency

-

prevents mold growth

-

keeps room temperatures stable

Tony’s insulation essentials:

-

rigid foam board

-

acoustic insulation strips

-

sealed sidewalls

-

vapor barrier

-

no thermal bridging

If you’ve ever felt a draft from a wall AC, it was because someone skipped this step.

(Reference: Mechanical Noise Prevention and System Balancing Principles)

5. Preparing the Electrical: Wall ACs Need More Than “Just a Plug”

Most wall ACs require:

-

a dedicated 115V or 230V circuit

-

correct breaker size

-

proper grounding

-

proper outlet placement

-

correct wire gauge

Tony checks:

-

outlet height

-

wire routing

-

breaker panel

-

GFCI requirements

-

voltage consistency

-

surge protection

Heat pump wall units especially need correct electrical — otherwise they short cycle or shut down under load.

Tony won’t install a high-capacity wall unit on a shared electrical circuit. Ever.

6. Sliding the Unit Into the Sleeve: Alignment Matters

Here’s where most DIY installs mess up.

The AC doesn’t just slide in — it must lock into place exactly right.

Tony checks:

✔ proper rail engagement

✔ no obstruction against coil face

✔ perfect alignment with sleeve lips

✔ correct tilt forward

✔ electrical cord path

✔ no insulation bunching

✔ weather stripping compression

If the unit sits crooked, it will:

-

vibrate

-

rattle

-

drain poorly

-

run loud

-

cool poorly

This is precision work, not brute force.

(Reference: Air Distribution and Duct Sizing Reference)

7. Exterior Finishing: The Part That Makes the Job Look “Professionally Done”

Once the unit is in, Tony finishes the exterior properly — this step makes the difference between a clean install and a sloppy eyesore.

Exterior work includes:

-

sealing the sleeve’s rear flange

-

adding drip edge (if needed)

-

installing trim for siding

-

weatherproof caulking

-

painting or color matching

-

ensuring correct drainage path

A good exterior finish:

-

prevents water intrusion

-

reduces bugs

-

increases efficiency

-

looks clean and symmetrical

8. Interior Finishing: Trim, Sealing & Aesthetic Details

Inside the home, Tony finishes the job cleanly.

Tony’s finishing steps:

-

interior trim around sleeve

-

foam closure around edges

-

sealing between AC chassis and sleeve

-

panel alignment

-

wall patching (if needed)

He leaves the install looking like the AC was built with the house, not “shoved in the wall.”

9. Testing the Unit: Airflow, Temperature, Noise & Drainage Checks

This is where Tony’s craftsmanship shows.

Tony tests:

✔ temperature split

✔ airflow direction

✔ drain slope effectiveness

✔ vibration level

✔ noise level

✔ electrical draw

✔ fan speed behavior

✔ thermostat accuracy

✔ heat pump mode (if included)

He also checks recirculation, making sure the unit isn’t sucking in its own hot exhaust — a common issue with deep sleeves.

Tony won’t leave until the unit:

-

runs quiet

-

drains correctly

-

cools fast

-

blows strong

-

responds instantly

-

stays level

(Reference: Equipment Matching and System Compatibility Guidelines)

10. Educating the Homeowner: Tony’s Final Walkthrough

Tony finishes every job the same way — with a homeowner briefing.

He walks you through:

-

filter cleaning

-

how to remove front panel

-

coil cleaning schedule

-

how defrost mode behaves (for heat pumps)

-

how to reduce noise

-

how to improve airflow circulation

-

what maintenance you MUST do every season

-

what noises are normal

-

what noises mean trouble

Most installers skip this step.

Tony never does.

11. Common Install-Day Problems Tony Avoids — But Most DIYers Hit

Tony has fixed hundreds of failed DIY installs.

Here are the mistakes he sees most:

❌ Sleeve tilted inward

Results in water pouring inside the home.

❌ Sleeve too deep

AC overheats because airflow chokes.

❌ Insulation missing

Creates drafts, noise, and mold.

❌ Wrong electrical

Trips breakers or destroys capacitors.

❌ Unit not anchored

Vibrates, rattles, and makes neighbors angry.

❌ Wrong size hole

Causes structural damage or crooked alignment.

❌ No sealing

Invites bugs, moisture, and cold drafts.

❌ Trying to cool the whole house with one wall unit

Not going to happen.

12. Tony’s Final Verdict: A Through-the-Wall AC Should Last 10–15 Years — If Installed Right

A wall AC doesn’t need to be noisy, leaky, or ugly.

When installed properly, it cools like a champ and lasts a decade or more.

Tony’s summary:

✔ Correct measurements

✔ Proper sleeve

✔ Perfect slope

✔ Tight seal

✔ Good insulation

✔ Solid electrical

✔ Clean interior finishing

✔ Full testing

✔ Homeowner training

If you follow these steps, your wall AC will deliver:

-

fast cooling

-

low noise

-

long lifespan

-

efficient operation

-

zero leaks

-

perfect fit

Installation day doesn’t have to be stressful — not when Tony is in charge.

Let's know which wall unit you should choose in the next blog.