🏡 1. Introduction — The Coil That Keeps You Cool (Until It Doesn’t)

Your HVAC system’s evaporator coil is the unsung hero that keeps your home comfortable. Hidden inside your indoor unit, it’s responsible for pulling heat out of your indoor air so that your AC or heat pump can deliver cool, refreshing airflow.

But when that coil starts to fail? You’ll notice it — maybe not right away, but through subtle shifts: weaker cooling, higher energy bills, strange noises, or even humidity creeping back into your home.

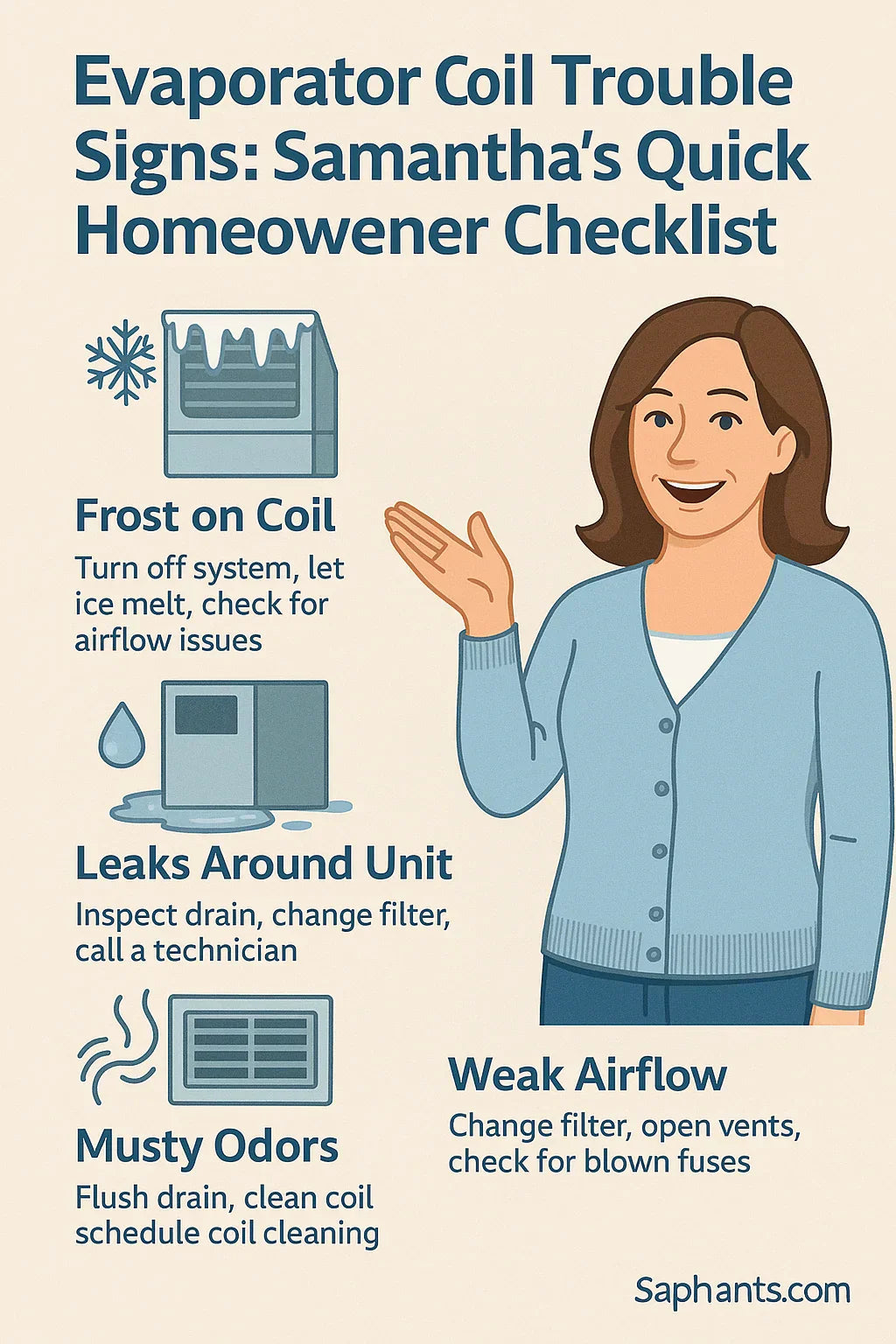

As Samantha Reyes, a homeowner who learned this lesson firsthand, I’ll help you understand the early warning signs of a bad evaporator coil, the causes behind those symptoms, and the fixes that can save your system (and your wallet) before it’s too late.

📎 For a quick technical refresher, check out HVAC.com’s guide on how evaporator coils work.

🔍 2. How Your Evaporator Coil Works — A Quick Refresher

The evaporator coil is located inside your air handler or furnace, usually right above the blower fan. When your system runs:

-

The blower fan pulls warm indoor air through return ducts.

-

That air passes over the cold evaporator coil, which is filled with refrigerant.

-

The refrigerant absorbs heat and moisture from the air, turning from liquid to vapor.

-

The cooled, dehumidified air is then pushed back into your home through supply vents.

If this process breaks down, even slightly, your entire cooling system’s performance drops.

Energy.gov notes that dirty or failing coils are among the top reasons for decreased AC efficiency and higher energy bills.

⚠️ 3. The Most Common Signs of a Bad Evaporator Coil

When your coil starts to fail, it often sends warning signs long before a total breakdown. Here’s what to look for:

❄️ 1. Ice Buildup on the Coil or Refrigerant Lines

-

You may notice frost forming on the copper tubing or even inside the air handler.

-

This happens when the refrigerant inside the coil can’t properly absorb heat — often due to low refrigerant or restricted airflow.

-

If left unchecked, it can lead to a frozen coil, preventing any cooling altogether.

🌬️ 2. Weak or Warm Airflow

-

The air coming from your vents feels warm, weak, or inconsistent.

-

This could mean the coil is dirty, corroded, or partially clogged — blocking heat exchange and airflow.

💧 3. Water Leaks Around the Air Handler

-

Condensation naturally forms on the coil, but if the drain pan or line is blocked, or the coil is overfreezing, you’ll see water pooling nearby.

-

Persistent leaks can cause mold, corrosion, and even damage flooring or ceilings.

⚙️ 4. Strange Hissing or Bubbling Sounds

-

These sounds are a telltale sign of a refrigerant leak.

-

When refrigerant escapes, pressure drops — causing bubbles or hiss as air enters the coil or liquid leaks out.

-

This is one of the most common causes of early coil failure.

💨 5. High Energy Bills for No Clear Reason

-

If your electric bill suddenly spikes, but your usage hasn’t changed, your HVAC may be running longer cycles due to a failing coil.

-

The coil isn’t transferring heat efficiently, so your system compensates by running harder.

🌫️ 6. Unusual Smells or Moldy Odors

-

The coil’s damp environment can attract mildew and bacteria, especially if the coil is dirty or constantly wet from leaks.

-

A “musty” or “dirty sock” smell from your vents often means microbial buildup on the coil.

HVAC Know It All calls these symptoms the “invisible killers” of HVAC efficiency, warning that neglecting early coil issues can lead to compressor burnout.

🧠 4. Why Coils Fail — The Hidden Causes Behind the Symptoms

Understanding what causes coil failure helps you prevent it in the future.

🧼 1. Dirt and Dust Buildup

Even with a clean air filter, fine dust can settle on coil fins. Over time, it acts like insulation — blocking heat transfer.

⚙️ 2. Corrosion (Formicary Corrosion)

Copper coils are prone to small pinhole leaks caused by chemical reactions between the metal and airborne contaminants like cleaning fumes.

-

This microscopic corrosion slowly reduces refrigerant pressure.

-

The result? Gradual cooling loss and refrigerant leaks.

🧯 3. Refrigerant Leaks

Leaking refrigerant causes low pressure in the coil, which leads to freezing and compressor strain.

🧊 4. Poor Airflow or Dirty Filters

Restricted airflow prevents proper heat exchange, which can cause ice buildup on the coil and damage the fins.

🧩 5. Mismatched or Incorrectly Sized Coils

If your coil doesn’t match your AC or heat pump in tonnage or refrigerant type, it can cause ongoing performance issues and shorten the coil’s lifespan.

Carrier’s SEER2 system matching guide warns that mismatched components can “reduce total system efficiency by 20% or more.”

🧰 5. Quick Homeowner Troubleshooting — What You Can Check Yourself

Before calling a technician, here are a few safe steps you can take to identify potential coil problems:

✅ Step 1: Check for Ice or Moisture

Open your air handler access panel (if safe) and look for frost, condensation, or water pooling.

✅ Step 2: Inspect the Air Filter

If it’s dirty, replace it. Restricted airflow is one of the most common and easily fixable causes of coil problems.

✅ Step 3: Listen and Smell

Notice any hissing or bubbling sounds near the indoor unit, or musty odors from the vents. These point to refrigerant leaks or bacterial buildup.

✅ Step 4: Monitor Air Temperature

Hold your hand over a supply vent. The air should be 15–20°F cooler than the return air (for cooling mode). If it’s not, your coil may not be absorbing heat efficiently.

✅ Step 5: Check Your Energy Bills

If your system runs longer than usual, and your bill jumps without a thermostat change, your coil may be losing capacity.

Energy Star’s HVAC maintenance guide recommends monthly filter checks and coil cleaning as the best way to prevent performance drops.

🔧 6. Professional Diagnosis and Fixes

If your coil shows clear warning signs, it’s time to call in a certified HVAC technician. Here’s what they’ll typically do:

1️⃣ Pressure Test for Leaks

They’ll check refrigerant pressure and use leak-detection tools or dye to find tiny leaks invisible to the eye.

2️⃣ Inspect Coil Fins and Airflow

Technicians clean and straighten fins to restore airflow and test for restrictions.

3️⃣ Evaluate Refrigerant Charge

If refrigerant is low, they’ll check for leaks before refilling — simply “topping off” without addressing leaks is a temporary and costly fix.

4️⃣ Test Evaporator and Condenser Compatibility

They’ll ensure your coil matches your condenser in capacity, refrigerant type (R-410A or R-32), and orientation (vertical, horizontal, or downflow).

5️⃣ Recommend Coil Repair or Replacement

If leaks are widespread or corrosion severe, replacement is often the smarter long-term option.

Goodman Manufacturing’s evaporator coil guide notes that newer aluminum coils are far more resistant to corrosion and leaks than older copper ones.

💸 7. Repair vs. Replace — Knowing When to Upgrade

| Problem Type | Repair Cost | When to Replace |

|---|---|---|

| Minor refrigerant leak | $250–$600 | If coil is over 10 years old |

| Dirty or clogged coil | $150–$400 (cleaning) | If cleaning doesn’t restore performance |

| Severe corrosion | $800–$1,200 | When leaks are widespread |

| Coil replacement | $1,100–$1,800 | Best paired with new condenser for SEER2 match |

If your system is 10–15 years old, replacing both the coil and the outdoor unit ensures compatibility, new refrigerant (R-32), and longer warranty coverage.

🧼 8. Preventing Coil Failure — Samantha’s Maintenance Tips

I learned this the hard way after a coil replacement a few summers ago. Now, I stick to a simple seasonal checklist:

-

Replace filters every month during peak season.

-

Have your HVAC tech clean the coil annually to remove dust and debris.

-

Check drain lines for clogs to avoid water buildup.

-

Keep supply and return vents unblocked.

-

Ask about coil coatings (like epoxy) to prevent corrosion, especially if you live near the coast.

-

Make sure the coil matches your refrigerant type and SEER2-rated condenser.

Lennox’s coil maintenance tips emphasize that a clean coil improves energy efficiency by up to 15%.

🧭 9. When to Call a Pro

Call a licensed HVAC technician immediately if you notice:

-

Warm air blowing during cooling mode.

-

Ice forming on lines or the coil.

-

Persistent leaks around your indoor unit.

-

Strange hissing or gurgling sounds.

-

Unexplained energy bill spikes.

Ignoring these symptoms can lead to compressor damage — a far more expensive repair than replacing the coil itself.

🌟 10. Samantha’s Wrap-Up — Don’t Wait Until It Breaks

Your evaporator coil isn’t just another HVAC part — it’s the heart of your comfort system.

Catching problems early saves you hundreds of dollars and keeps your system efficient for years.

Here’s my quick homeowner takeaway:

✅ Know the early warning signs (ice, leaks, weak airflow, strange sounds).

✅ Don’t ignore rising bills or warm air.

✅ Clean and inspect coils annually.

✅ Always match coil size and refrigerant type when replacing parts.

✅ Invest in professional maintenance — it’s cheaper than a new compressor.

If you treat your coil with care, it’ll reward you with years of quiet, reliable comfort — and lower utility bills.

In the next topic we will know more about: Installation Guide: Things to Consider Before Replacing Your Evaporator Coil