🏡 1. Introduction — The Hidden Component That Keeps Everything Cool

If your HVAC system is the heart of your home’s comfort, then the evaporator coil is its lungs — quietly working behind the scenes to breathe cool, refreshing air into every room.

This coil, tucked inside your furnace or air handler, is where warm indoor air meets chilled refrigerant. It’s the point of transformation — where heat is pulled from your home and moisture condenses out of the air.

But when the coil fails — due to corrosion, leaks, or blockages — everything else suffers: your comfort, your energy bills, and your system’s lifespan.

Replacing an evaporator coil is a major step in keeping your HVAC system running efficiently. It’s not a DIY project — it’s a careful process that requires the right coil size, refrigerant match, and professional installation to ensure safe, long-lasting performance.

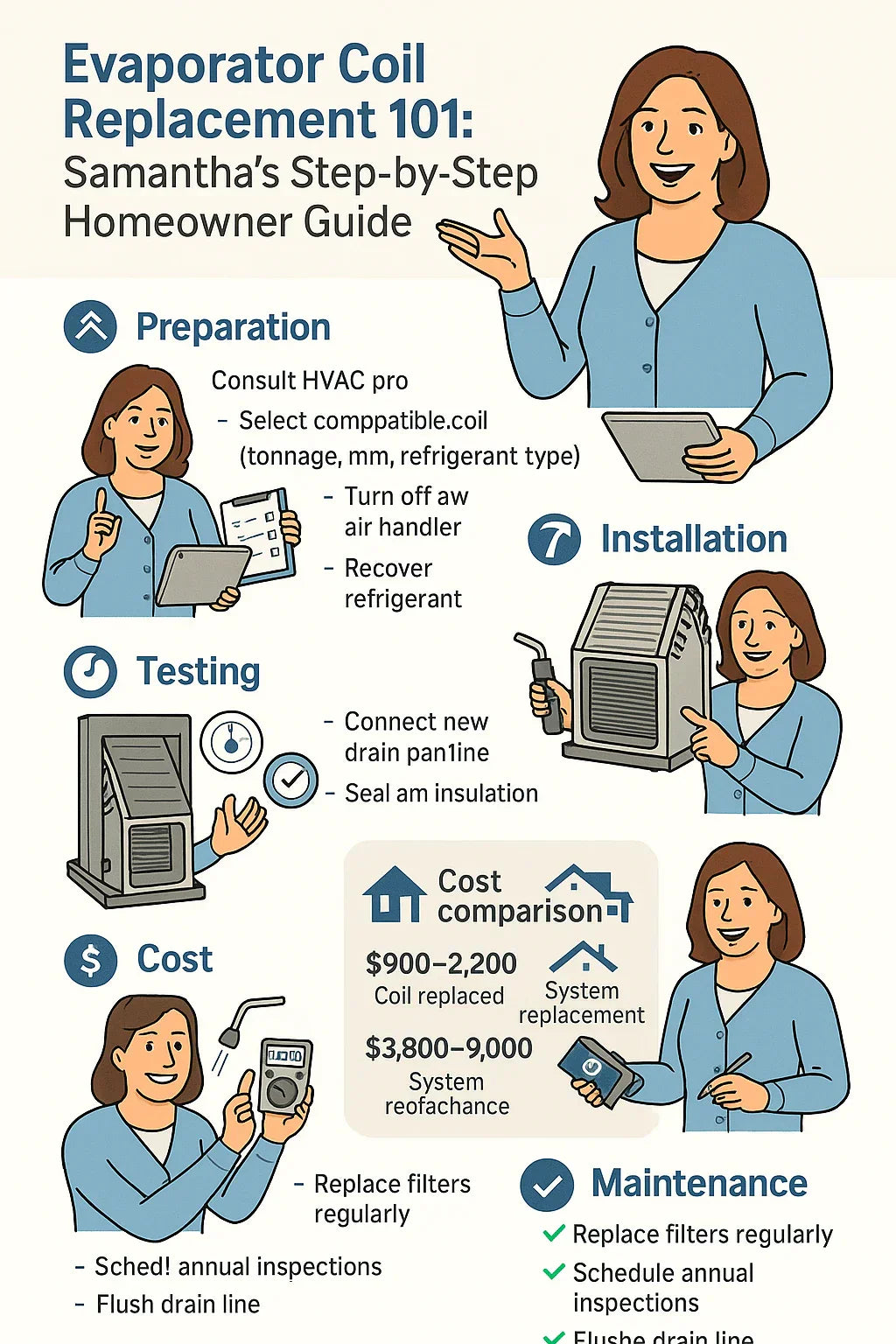

As Samantha Reyes, a homeowner who went through the process myself, I’ll break down exactly what to expect — from signs you need a replacement to the technical steps pros take, how to confirm your system is matched, and how to keep it in perfect shape afterward.

📎 Before we dive in, HVAC.com offers an excellent explanation of what an evaporator coil does and why it’s critical for comfort.

⚙️ 2. Why Evaporator Coils Fail — And When Replacement Is the Only Option

Even with good maintenance, coils eventually wear down. Most last 10–15 years, but environmental factors, refrigerant type, and usage patterns can shorten that.

Here are the top reasons coils need replacement:

🧊 1. Refrigerant Leaks

Tiny holes called formicary corrosion form inside copper tubing due to moisture, VOCs (volatile organic compounds), and airborne contaminants. These leaks slowly reduce refrigerant charge and cooling performance.

Over time, your system starts to “short cycle” — running longer but cooling less.

⚙️ 2. Corrosion

In humid or coastal environments, salt air accelerates metal corrosion. Aluminum coils resist this better than copper, which is why most modern coils are now all-aluminum.

🧼 3. Dirt and Debris Buildup

Even with clean filters, fine dust and pet dander cling to coil fins. This layer acts as insulation, preventing heat transfer and causing your system to work overtime.

⚡ 4. Improper System Matching

If your outdoor condenser was replaced recently but your indoor coil wasn’t, mismatched tonnage or refrigerant can create pressure imbalance and early coil failure.

💧 5. Drainage and Moisture Issues

A clogged condensate line can cause water to back up into the coil housing, leading to rust, mold, and performance loss.

Energy.gov highlights that poor airflow and dirty coils are among the top causes of HVAC inefficiency — up to 30% loss in some homes.

🧩 3. Step One — Verify Compatibility Before You Buy

Matching your new coil to your system isn’t optional — it’s essential. The wrong coil can lead to higher energy bills, warranty loss, or even compressor failure.

Here’s what needs to match:

✅ 1. Tonnage (Capacity)

This refers to the cooling capacity — measured in tons.

-

1 ton = 12,000 BTUs/hour of cooling power.

If your outdoor unit is 3 tons (36,000 BTUs), your coil should be, too.

✅ 2. Refrigerant Type

Your coil must be rated for the same refrigerant your system uses:

-

R-410A: Used in systems from the early 2000s through 2024.

-

R-32: The new, more eco-friendly refrigerant replacing R-410A.

Mixing refrigerants is unsafe and illegal — they operate at different pressures.

✅ 3. Airflow Orientation

-

Upflow: Air moves up through the coil (usually in basements).

-

Downflow: Air moves downward (common in attics).

-

Horizontal: Air moves sideways (crawl spaces and tight installs).

Your coil must be oriented for your ductwork.

✅ 4. Cased vs. Uncased

-

Cased coils come in an insulated metal housing, pre-fitted for easy installation.

-

Uncased coils are bare and used in older or custom systems where space or airflow needs modification.

✅ 5. Coil Style

-

A-Coil: Standard and efficient; shaped like a letter “A.”

-

N-Coil: Compact, often used in modern vertical furnaces.

-

Slab Coil: Flat and ideal for tight or horizontal installations.

Goodman Manufacturing’s coil selector helps homeowners confirm which coil models are compatible with specific condensers.

If you’re upgrading to a new SEER2 system, your coil must also be rated to match that efficiency.

Carrier’s SEER2 efficiency guide explains how mismatched coils can drop your system’s performance below its advertised rating.

🧰 4. Step Two — Understand the Full Installation Process

Even though coil replacement is a professional task, understanding the process helps you ensure it’s done right — and helps you spot shortcuts that could void warranties.

🔌 1. System Shutdown and Refrigerant Recovery

Your technician turns off the power and safely recovers refrigerant from the system using EPA-approved equipment. Venting refrigerant into the air is illegal.

⚙️ 2. Accessing the Coil

The technician removes the access panel from your air handler or furnace, exposing the old coil and drain pan.

🔧 3. Disconnecting Lines

Refrigerant lines are disconnected, and the old coil is lifted out carefully to avoid damage to the plenum or surrounding ducts.

💧 4. Drain Pan and Line Check

Before installing the new coil, the technician checks for clogs, corrosion, or microbial growth in the drain pan and condensate line. These are replaced if needed.

🧱 5. Installing the New Coil

The new coil is mounted, leveled, and sealed. Insulation and foil tape are applied to ensure airtight performance.

🔩 6. Brazing and Pressure Testing

Copper connections are brazed (heat-fused) with nitrogen flowing through the lines to prevent oxidation. Then, the entire system is pressure-tested for leaks.

🧮 7. Evacuation and Charging

The technician uses a vacuum pump to remove moisture and air, then refills the system with the correct refrigerant amount based on manufacturer specs.

⚡ 8. System Start-Up and Calibration

Finally, they test the airflow, temperature drop (15–20°F difference between return and supply air), and refrigerant pressures.

Trane’s installation standards stress that 90% of performance problems stem from incorrect refrigerant charging and airflow calibration.

🧯 5. Tools and Materials Used

You don’t need to handle these yourself, but it’s good to recognize what a proper install involves.

Professional Equipment Includes:

-

Refrigerant recovery machine

-

Nitrogen tank and regulator

-

Brazing torch & fittings

-

Vacuum pump and manifold gauges

-

Coil cleaner & fin comb

-

Sealant and insulation tape

-

Refrigerant scale for accuracy

-

Leak detection tools

HVAC Know It All highlights that skipping nitrogen purging during brazing can leave carbon buildup, leading to leaks months later.

💸 6. Step Three — Understand the True Cost

A coil replacement can range from $900–$2,200 depending on system size, refrigerant, and labor.

| Coil Size | Equipment Cost | Installed Cost (2025 Average) | Common Application |

|---|---|---|---|

| 1.5–2 Ton | $350–$500 | $900–$1,200 | Apartments, small homes |

| 2.5–3 Ton | $450–$650 | $1,100–$1,500 | Mid-size homes |

| 3.5–4 Ton | $600–$850 | $1,400–$1,800 | Large single-story homes |

| 5 Ton | $700–$1,000 | $1,700–$2,200 | Multi-level or large homes |

Cost Factors Include:

-

Location of your indoor unit (attic = more labor).

-

Refrigerant type (R-32 coils slightly costlier upfront but save energy).

-

Drain line and insulation replacements.

-

Local labor rates.

-

Warranty coverage (parts often free if still under manufacturer warranty).

🧊 7. Step Four — Post-Installation Verification Checklist

Once the new coil is in, you should verify a few things before your technician leaves:

✅ Matching Capacity: Coil tonnage matches outdoor condenser.

✅ Refrigerant Type: Same refrigerant in coil and outdoor unit.

✅ Refrigerant Charge: System pressures within factory specifications.

✅ Drain Line Flow: No leaks; drain pan clean and properly sloped.

✅ Air Temperature Drop: Return-to-supply difference between 15–20°F.

✅ No Air Leaks: All duct joints sealed and insulated.

Energy Star’s HVAC verification checklist includes refrigerant charge, airflow, and duct sealing as the top three performance indicators.

🔧 8. Step Five — Should You Replace the Coil or the Whole System?

If your coil is failing, you might be tempted to replace just the coil. But here’s when that’s smart — and when it’s not.

| System Age | Recommended Action | Why |

|---|---|---|

| < 5 years | Replace coil only | System still under warranty |

| 6–10 years | Inspect both | Coil replacement may be temporary fix |

| 10+ years | Replace full system | Older refrigerant, lost efficiency, outdated SEER rating |

New SEER2 systems operate under higher efficiency standards — meaning the indoor coil and outdoor condenser must be tested as a pair.

Carrier’s SEER2 transition update warns that mismatched coils can invalidate manufacturer performance ratings.

💧 9. Step Six — Maintenance After Replacement

Once your coil is installed, keep it in peak condition with consistent care.

🧼 Samantha’s Maintenance Routine:

-

Replace filters monthly during summer.

-

Have coils cleaned professionally every spring.

-

Inspect for condensation or rust on the pan or fittings.

-

Check refrigerant pressures annually.

-

Flush drain lines with vinegar or cleaning tablets every 3 months.

-

Keep ducts clear and sealed.

Lennox’s coil maintenance guide shows that coil cleanliness improves heat transfer and reduces energy use by 15%.

🧠 10. Samantha’s Experience — What I Learned From My Replacement

When my coil failed, I made two mistakes:

-

I delayed the replacement, trying to “refill” refrigerant instead of addressing the real issue.

-

I didn’t confirm compatibility between my coil and my older outdoor unit.

The result? I spent more over two summers on energy bills than I saved by delaying.

When I finally replaced my system with a Goodman 2.5-ton R-32 coil and heat pump combo, my system ran quieter, cooled faster, and dropped my summer electric bill by 15%.

The moral: replacing a coil isn’t just maintenance — it’s an investment in comfort and efficiency.

🔒 11. Warranty, Efficiency, and SEER2 Compliance

Modern systems are factory-tested to meet specific SEER2 ratings only when their evaporator coil, condenser, and air handler are paired correctly.

To protect your investment:

✅ Register your coil within 60 days of installation.

✅ Use a licensed contractor — DIY installation voids warranties.

✅ Keep invoices and serial numbers for proof of pairing.

✅ Replace both components if your old condenser uses R-410A and your new coil uses R-32.

🌟 12. Samantha’s Final Homeowner Checklist

Before you schedule your coil replacement, review this summary:

✅ Match coil tonnage with condenser.

✅ Match refrigerant type (R-410A or R-32).

✅ Choose the right orientation (upflow, downflow, or horizontal).

✅ Select cased coils for easier, airtight installation.

✅ Request nitrogen testing and vacuum evacuation.

✅ Confirm drain line and pan integrity.

✅ Register for warranty coverage immediately.

✅ Schedule annual maintenance.

Your evaporator coil may be hidden, but it’s the backbone of your comfort. When replaced correctly, it ensures quieter operation, better humidity control, and lower energy costs — all while extending your system’s life for years to come.

In the next topic we will know more about: Cost Breakdown — How Much Does an Evaporator Coil Replacement Really Cost in 2025?