For many businesses, upgrading or installing a 10-ton packaged rooftop air conditioner (RTU) is one of the biggest capital investments they’ll make in building operations. These systems provide reliable, large-scale cooling, but the true cost isn’t just about the sticker price of the equipment.

To make a smart, ROI-driven decision, you need to understand:

👉 How much the equipment itself costs

👉 What drives installation expenses

👉 The ongoing operating and maintenance costs

👉 How rebates, tax incentives, and efficiency savings affect ROI

This guide breaks it all down—so you can budget accurately, avoid hidden costs, and calculate the long-term return on your investment.

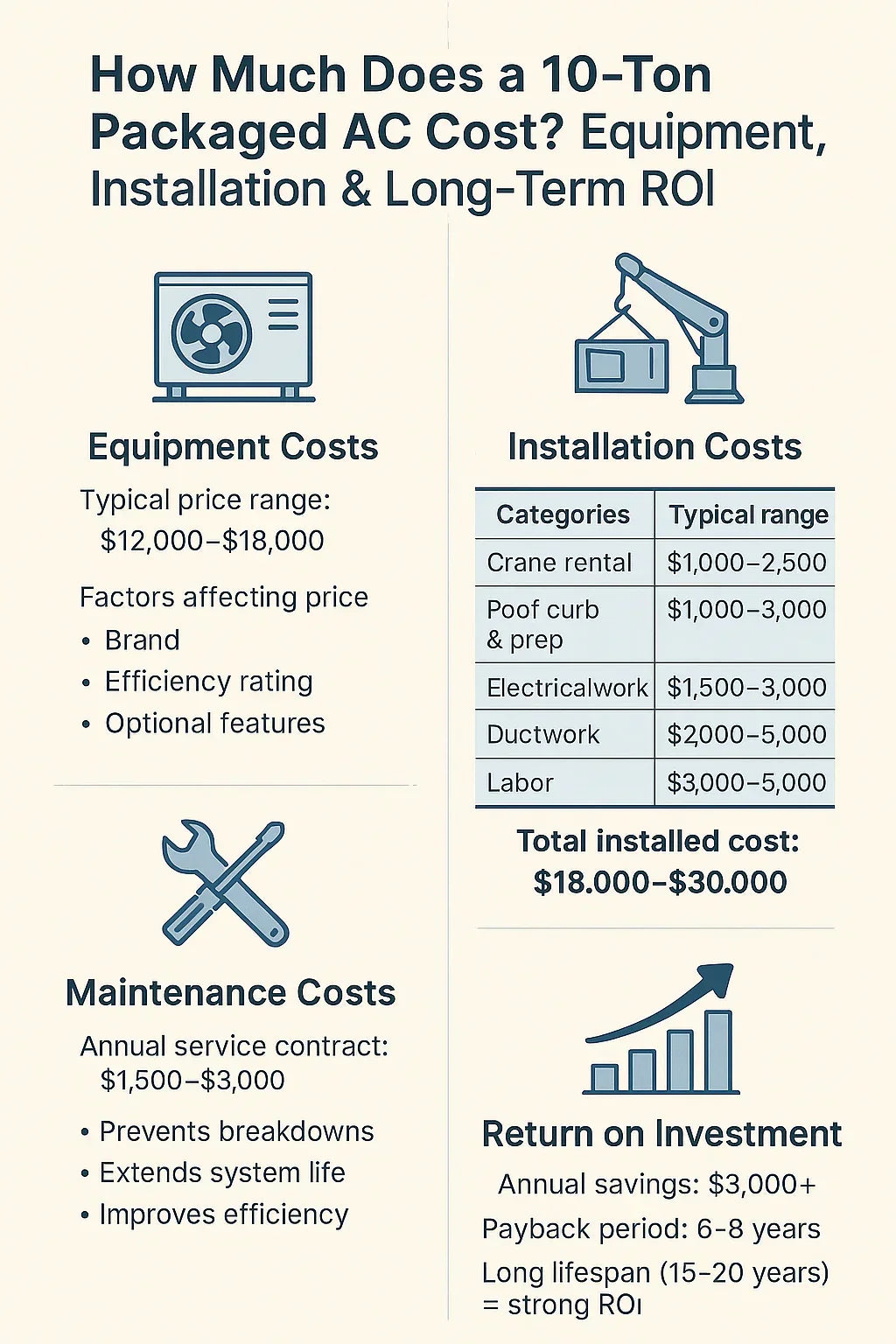

📦 Equipment Costs: What You’ll Pay Upfront

The starting point for any budget is the equipment itself.

Typical Price Range

-

$12,000–$18,000 for a new 10-ton packaged rooftop unit (RTU).

This covers the cabinet containing the compressor, condenser, evaporator coil, blower, and controls in one self-contained system.

Factors That Affect Equipment Price

-

Brand

-

Daikin: Known for energy-efficient, high-IEER2 models.

-

Trane: Premium durability, slightly higher price.

-

Carrier: Balanced performance, strong service network.

-

-

Efficiency Rating

-

Units rated with IEER2 (Integrated Energy Efficiency Ratio 2) determine energy savings.

-

Higher IEER2 = higher upfront cost, but lower utility bills.

-

-

Configuration & Options

-

Economizers for free cooling using outdoor air.

-

Gas/electric hybrid heating add-ons.

-

Smart controls for building automation systems (BMS).

-

👉 Example: A Daikin 10-ton, 15 IEER2 packaged AC will cost more upfront than a baseline 13 IEER2 competitor—but may save $3,000/year in energy costs.

📖 Reference: Daikin Applied – Packaged Rooftop Units

🏗️ Installation Costs: Beyond the Equipment

Many businesses underestimate installation expenses. In reality, installation often equals—or even exceeds—the equipment cost.

Common Installation Cost Categories

| Category | Typical Range | Notes |

|---|---|---|

| Crane rental | $1,000–$2,500 | Needed to lift RTU to rooftop |

| Roof curb & prep | $1,000–$3,000 | Custom curb, flashing, roof reinforcement |

| Electrical work | $1,500–$3,000 | 208/230V 3-phase, breaker, disconnect |

| Ductwork modifications | $2,000–$5,000 | Sealing, resizing, custom sheet metal |

| Labor | $3,000–$5,000 | HVAC crew time, typically 2–3 days |

Total Installed Cost

$18,000–$30,000 for a full equipment + installation package.

What Makes Installation More Expensive?

-

Accessibility

-

If the building has limited crane access, costs rise (permits, street closures, larger cranes).

-

-

Roof Condition

-

If the roof can’t support the RTU, reinforcement is required.

-

-

Retrofit vs. New Construction

-

Replacing an old RTU often requires duct modifications.

-

New buildings may save since ductwork is already designed for the system.

-

📖 Reference: HVAC Cost Guide

⚡ Operating Costs: Energy Efficiency & Monthly Bills

A 10-ton packaged AC consumes a lot of power—so operating costs quickly become the biggest factor in total ownership.

How Energy Efficiency Affects Bills

-

Cooling capacity: 120,000 BTUs/hour.

-

Old units (8–10 IEER): $12,000–$14,000/year in cooling costs.

-

Modern high-efficiency (15 IEER2): ~$9,000/year.

👉 Annual savings: $3,000–$5,000 by upgrading.

Example: Daikin 15 IEER2 vs. 12 IEER2 Competitor

-

Annual run time: ~2,000 hours (typical for U.S. office space).

-

Energy cost per kWh: $0.12 (national average).

-

Daikin 15 IEER2 → 20%+ less energy consumed.

-

Payback in 6–8 years just on efficiency.

📖 Reference: ENERGY STAR – Commercial HVAC Efficiency

🧾 Maintenance Costs: Protecting Your Investment

A new RTU isn’t a “set it and forget it” system. Ongoing maintenance is essential to keep efficiency high and extend lifespan.

Typical Maintenance Expenses

-

Annual service contract: $1,500–$3,000/year.

-

Includes filter changes, coil cleaning, electrical inspections, refrigerant checks.

What Happens If You Skip Maintenance?

-

Dirty coils increase energy use by 10–20%.

-

Missed refrigerant leaks can destroy compressors ($5k–$7k repair).

-

Lifespan drops from 15–20 years → 8–12 years.

👉 Preventative maintenance = $1 saves $3–$5 in energy + repair costs.

📖 Reference: ASHRAE – Preventive Maintenance Guidelines

🎁 Rebates, Incentives & Tax Deductions

One of the most overlooked parts of HVAC budgeting: incentives.

Federal & State Incentives

-

DSIRE database lists local rebates for high-efficiency RTUs.

-

Utility providers often offer $500–$2,500 per unit for ENERGY STAR-qualified systems.

Tax Deduction: Section 179D

-

Commercial building owners may deduct up to $5 per sq. ft. for energy-efficient upgrades (per Inflation Reduction Act updates in 2023).

Example

-

Installed cost: $25,000

-

Utility rebate: $2,000

-

Section 179D deduction: $15,000 (based on building size)

-

Net effective cost: $8,000 less

📖 Reference: DSIRE – Energy Incentives Database

📈 Long-Term ROI: The Payback Equation

Here’s a simplified ROI scenario for a business investing in a Daikin 10-ton RTU:

-

Installed cost: $25,000

-

Annual energy savings: $3,000 (vs. old system)

-

Annual maintenance: $2,000

-

Net annual benefit: $1,000 savings + improved comfort + reduced downtime

-

Rebates/incentives: $2,500 upfront

👉 Payback period: ~7.5 years

👉 System lifespan: 15–20 years

Meaning: After payback, you’re enjoying 8–12 years of net savings.

🏆 Key Takeaways

-

Equipment: $12k–$18k

-

Installation: $6k–$12k

-

Total Installed Project: $18k–$30k

-

Operating Costs: $9k–$12k/year (lower with high efficiency)

-

Maintenance: $1.5k–$3k/year

-

ROI: 6–8 years payback with incentives

👉 A Daikin 10-ton packaged rooftop AC isn’t just an equipment upgrade—it’s a long-term financial strategy. When properly installed and maintained, it pays for itself in energy savings, tax incentives, and reliability.

In the next topic we will know more about: Do 10-Ton Packaged ACs Qualify for Rebates or Tax Incentives in 2025?