A Daikin 10-ton commercial packaged air conditioner (RTU) is one of the most valuable assets your business can own. It keeps your employees productive, your customers comfortable, and your energy bills manageable. But like any high-performance machine, it can’t run at peak performance forever without proper care.

Here’s the truth:

👉 Even the most durable Daikin rooftop unit will lose efficiency, break down more often, and fail years early if maintenance is ignored.

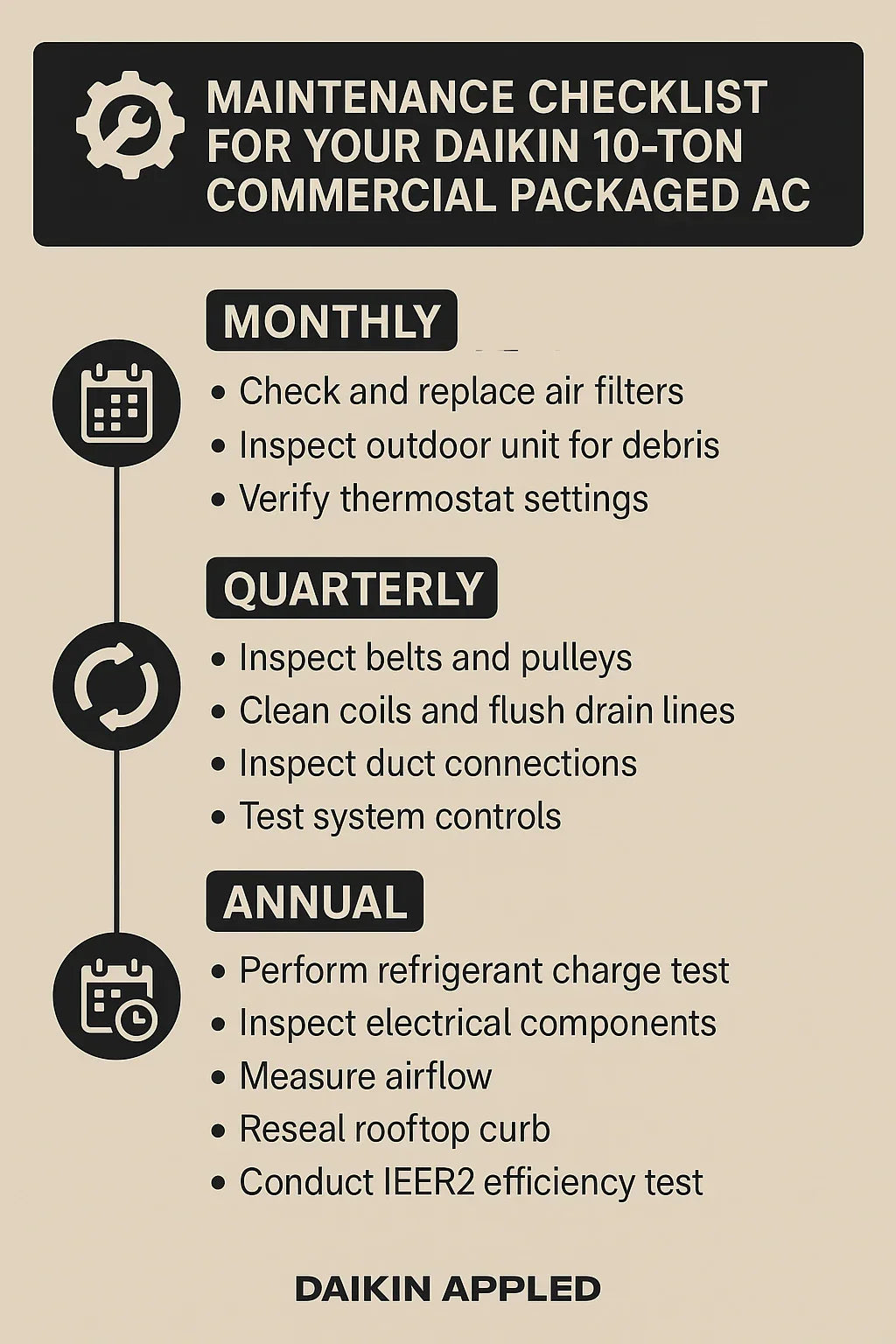

That’s why having a structured, preventative maintenance plan is crucial. This guide provides a step-by-step checklist—monthly, quarterly, and annually—to help you protect your investment, minimize downtime, and maximize ROI.

❄️ Why Maintenance Matters for Your Daikin 10-Ton Packaged AC

Before diving into the checklist, let’s understand why maintenance isn’t optional.

1. Protects Efficiency

-

Dust, debris, and clogged filters force the unit to work harder.

-

A dirty coil can cut efficiency by 10–20%, translating to hundreds or thousands of dollars annually.

2. Extends Lifespan

-

A well-maintained RTU lasts 15–20 years.

-

Neglected units may fail in just 8–12 years, forcing costly replacements.

3. Saves Money

-

Preventative maintenance reduces the risk of emergency repairs, which are often 2–3x more expensive than scheduled service.

4. Ensures Comfort & Safety

-

Balanced airflow keeps occupants comfortable.

-

Regular inspections prevent hazards like electrical shorts or refrigerant leaks.

📖 Reference: ENERGY STAR – HVAC Maintenance Best Practices

📅 Monthly Maintenance Tasks

Monthly tasks are simple but high-impact. Many of these can be done in-house by your facilities team.

🔲 Change or Clean Air Filters

-

Filters trap dust, pollen, and pollutants.

-

Dirty filters reduce airflow, overwork fans, and increase energy use.

-

Rule of thumb: Replace filters every 30 days in commercial environments (restaurants, retail, offices).

🔲 Inspect Outdoor Unit for Debris

-

Clear leaves, trash, or branches around the rooftop cabinet.

-

Ensure airflow is unobstructed.

🔲 Verify Thermostat Settings

-

Confirm programmed schedules match occupancy.

-

For energy savings, avoid unnecessary cooling during unoccupied hours.

💡 Pro Tip: Upgrading to a smart thermostat or BMS integration allows better scheduling and remote monitoring.

🔄 Quarterly Maintenance Tasks

Every 3 months, schedule a deeper inspection, ideally performed by a certified Daikin contractor.

🔲 Inspect Belts and Pulleys

-

Worn or loose belts reduce efficiency and can snap unexpectedly.

-

Adjust tension or replace if fraying is visible.

🔲 Clean Condenser and Evaporator Coils

-

Dirty coils block heat transfer.

-

Coils should be cleaned with a non-corrosive cleaner.

🔲 Flush Condensate Drain Lines

-

Blocked drains cause water backup, leaks, and mold growth.

-

Technicians should flush with a safe biocide or pressurized water.

🔲 Inspect Duct Connections

-

Look for loose seals, holes, or insulation damage.

-

Leaky ducts can waste 20–30% of conditioned air.

🔲 Test System Controls & Safety Switches

-

Ensure safeties shut down the unit during faults.

-

Verify thermostat communication and calibration.

📖 Reference: ASHRAE – Preventive Maintenance Guidelines

🗓️ Annual Maintenance Checklist

An annual inspection is the deep dive. This is where you ensure your Daikin 10-ton packaged AC is operating at peak performance.

🔲 Refrigerant Charge Test

-

Incorrect refrigerant levels reduce efficiency and can damage the compressor.

-

Technicians measure superheat and subcooling to ensure correct charge.

🔲 Electrical Inspections

-

Tighten loose lugs or wiring.

-

Inspect breakers, fuses, and disconnect box.

-

Measure voltage and amperage against Daikin specifications.

🔲 Inspect Compressor, Motors, Bearings

-

Check lubrication on motors and bearings.

-

Inspect compressor for unusual noise or vibration.

🔲 Measure Airflow

-

Technicians use airflow meters to verify proper CFM.

-

Adjust dampers if zones are unbalanced.

🔲 Rooftop Curb & Sealing

-

Inspect curb flashing for leaks.

-

Reseal insulation to maintain efficiency and prevent water damage.

🔲 IEER2 Efficiency Test

-

Annual performance tests confirm your unit is meeting its 15 IEER2 efficiency rating.

-

If efficiency is below spec, adjustments or coil cleaning may be required.

📖 Reference: Daikin Applied – Service and Support

🧰 Additional Best Practices

Beyond the standard schedule, here are pro tips to get even more life out of your unit.

-

Seasonal scheduling: Service in spring before cooling season, and fall before heating season (if heat included).

-

Logbook tracking: Maintain a maintenance logbook for warranty compliance and future troubleshooting.

-

Daikin-certified service: Always use Daikin-approved parts and authorized contractors.

-

Upgrade controls: Smart controls reduce unnecessary runtime and energy costs.

-

Plan for replacement: Even the best-maintained system will eventually age out. Start budgeting after 15 years.

📖 Reference: EPA – Energy Efficiency in Commercial Buildings

💵 The Cost of Neglect vs. Maintenance

It’s tempting to skip maintenance when the system seems to be working fine. But let’s compare costs:

| Scenario | Result | Cost Impact |

|---|---|---|

| Neglect | Dirty coils, clogged filters, refrigerant leaks | +20% higher energy bills |

| Neglect | Compressor failure due to poor refrigerant management | $4,000–$7,000 repair |

| Neglect | Shortened lifespan (10 years vs. 18 years) | Early $20k+ replacement |

| Maintenance | Annual service contract | $1,500–$3,000/year |

| Maintenance | Energy savings maintained | $1,500+/year saved |

👉 Bottom line: $1 invested in maintenance saves $3–$5 in repairs and energy costs.

🏆 Key Takeaways

Maintaining your Daikin 10-ton packaged AC isn’t just about avoiding breakdowns—it’s about protecting your bottom line.

-

✅ Monthly: Change filters, check thermostat, clear debris.

-

✅ Quarterly: Clean coils, inspect belts, flush drains, check controls.

-

✅ Annually: Deep dive—refrigerant, electrical, airflow, curb sealing, IEER2 test.

-

✅ Always: Keep a maintenance log, use Daikin-approved parts, and partner with certified technicians.

👉 With consistent care, your Daikin RTU can last 15–20 years, deliver optimal energy savings, and keep your building comfortable year-round.

In the next topic we will know more about: How Much Does a 10-Ton Packaged AC Cost? Equipment, Installation & Long-Term ROI