nstalling a 10-ton packaged rooftop air conditioner (RTU) is one of the biggest HVAC upgrades a small-to-mid-sized business can make. Unlike residential systems, these heavy-duty commercial units require careful planning, permits, crane lifts, and coordination between multiple contractors.

If you’re preparing for your first RTU installation—or replacing an aging unit—you might be wondering:

👉 What exactly happens during the installation process?

👉 How much should I budget?

👉 What hidden challenges could delay my project?

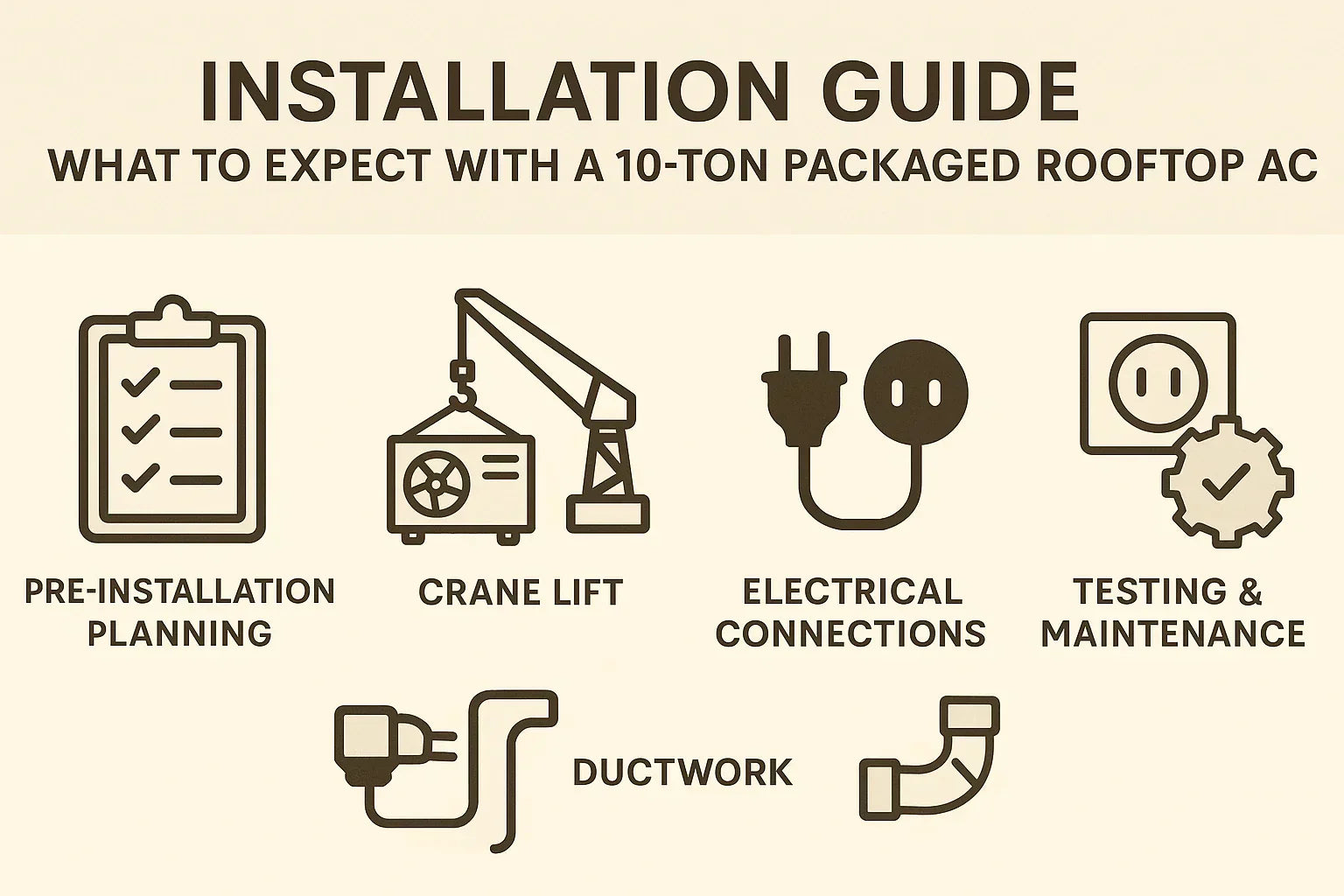

This in-depth guide will walk you through the entire process, step by step, so you know what to expect before, during, and after the installation of a 10-ton rooftop packaged AC.

🔎 Why Rooftop Packaged ACs Are Popular

A packaged rooftop unit (RTU) combines the compressor, condenser, evaporator, and blower into one single cabinet mounted outside the building.

Benefits for commercial spaces:

-

Space-saving: No bulky indoor equipment taking up valuable square footage.

-

Easier maintenance: Service technicians access the unit from the roof without disrupting daily operations.

-

Energy-efficient zoning: Multiple RTUs can serve different parts of a building.

-

Durability: Units are weather-hardened for outdoor conditions.

-

Lower noise: Mechanical noise stays outside, improving indoor comfort.

📖 Resource: ASHRAE – Commercial Rooftop HVAC Benefits

📝 Pre-Installation Planning

The most important stage of any RTU installation happens before the crane arrives.

1. Load Calculation (Manual N)

Installing the wrong size unit can be a costly mistake. Contractors perform a Manual N load calculation to ensure 10 tons (120,000 BTU/hour) is the right fit.

Factors considered:

-

Building square footage

-

Insulation quality and roof type

-

Number of occupants and daily traffic

-

Internal heat loads (kitchen equipment, lighting, servers)

-

Local climate data

💡 Oversizing leads to short cycling (inefficiency + higher wear). Undersizing results in poor comfort and overworked equipment.

2. Site Assessment

A technician will inspect your building to:

-

Ensure the roof structure can handle the 1,200–1,500 lb unit.

-

Identify crane lift access (street clearance, parking lot space).

-

Locate existing electrical service and ductwork connection points.

3. Permits & Code Compliance

Installing an RTU isn’t just about equipment—it’s also about compliance:

-

Building permits usually required.

-

Must meet DOE 2023 IEER2 efficiency standards.

-

Electrical work follows National Electrical Code (NEC).

-

Fire and rooftop safety standards enforced by local inspectors.

📖 Resource: U.S. DOE Commercial HVAC Standards

🚚 Delivery & Staging

When your RTU arrives, expect a large delivery truck with heavy equipment.

-

Weight: A 10-ton packaged unit weighs around 1,200–1,500 pounds.

-

Delivery: Brought on a flatbed, often requiring forklifts to stage it.

-

Staging area: Must be near crane access but clear of traffic.

-

Timing: Units remain crated until the day of lift to protect against weather and damage.

🏗️ Crane Lift & Roof Preparation

Perhaps the most dramatic and visible step of installation:

Rooftop Preparation

-

A roof curb (metal frame) is installed to anchor the RTU.

-

Ductwork and electrical conduit positioned to align with the new unit.

-

Roof inspected for structural integrity before crane day.

The Lift

-

A mobile crane (often 60–100 ft. boom) hoists the RTU into position.

-

Cost: $1,000–$2,500, depending on site accessibility and city permits.

-

Crew guides the unit onto the roof curb and bolts it in place.

-

Time: A well-coordinated lift may take under one hour, but staging and preparation can take all morning.

💡 Safety first: High winds or rain can postpone lifts.

🔌 Electrical & Ductwork Connections

Once the unit is in place, technicians connect it to your building systems:

Electrical

-

208/230V 3-phase power is standard for 10-ton units.

-

Dedicated circuit breaker required.

-

Local electrical code requires a service disconnect box within sight of the unit.

Ductwork

-

Supply and return ducts connect directly to the rooftop curb.

-

Duct seams sealed and insulated to minimize leakage.

-

May require sheet metal fabrication if retrofitting from an older RTU.

Controls

-

Thermostat wiring connected and tested.

-

Option to integrate with smart thermostats or a Building Management System (BMS) for advanced scheduling and monitoring.

📖 Resource: NFPA – National Electrical Code

🧪 Start-Up & System Testing

Before handing the unit over, technicians perform commissioning tests:

-

Refrigerant charge checked and balanced (factory-charged, but field adjustments may be needed).

-

Voltage and amperage confirmed against specs.

-

Airflow measured across supply/return ducts.

-

Thermostat operation verified.

-

Final check that the system meets efficiency standards (e.g., 15 IEER2 for Daikin models).

💵 Installation Cost Breakdown

A 10-ton RTU installation is a major investment. Here’s what to expect:

| Item | Typical Cost Range |

|---|---|

| Equipment (Daikin/Trane/Carrier) | $12,000–$18,000 |

| Crane rental | $1,000–$2,500 |

| Roof curb & prep | $1,000–$3,000 |

| Ductwork modifications | $2,000–$5,000 |

| Electrical work | $1,500–$3,000 |

| Labor | $3,000–$5,000 |

| Total Installed Cost | $18,000–$30,000 |

🛠️ Common Challenges During Installation

Even the best-planned projects can face obstacles:

-

Structural reinforcement required → Adds time and cost.

-

Limited crane access → May require closing streets or special city permits.

-

Weather delays → High winds stop crane operations.

-

Mismatched ducts → Requires custom fabrication, increasing labor.

-

Utility upgrades → Older buildings may need electrical service upgrades to handle a 10-ton load.

🔧 Post-Installation Maintenance

Once installed, your new RTU will need regular maintenance to maximize its 15–20 year lifespan:

-

Monthly: Replace filters.

-

Quarterly: Inspect belts, check coils, clean drains.

-

Annually: Full tune-up including refrigerant check, electrical testing, and coil cleaning.

Neglecting maintenance can reduce efficiency by 10–20% and cut years off system life.

📖 Resource: ENERGY STAR – Commercial HVAC Maintenance

🌱 Efficiency, Rebates & ROI

High-efficiency 10-ton units (like Daikin’s 15 IEER2 models) can:

-

Cut energy bills by 15–25% vs. older units.

-

Qualify for utility rebates.

-

Boost property value and attract tenants.

Check incentives: DSIRE Database of State Incentives

🏆 Key Takeaways

-

A 10-ton packaged RTU installation is a major project involving cranes, ductwork, electrical work, and permits.

-

Expect costs between $18k and $30k, depending on complexity.

-

The process includes pre-planning, crane lift, electrical/duct connections, and system testing.

-

Ongoing maintenance is critical to achieving the full 15–20 year lifespan.

-

Choosing a high-efficiency model (like Daikin’s 15 IEER2 unit) provides long-term savings and often qualifies for rebates.

👉 The bottom line: Properly installed and maintained, a 10-ton packaged rooftop AC is an investment that pays back in energy savings, reliability, and comfort.

In the next topic we will know more about: Maintenance Checklist for Your Daikin 10-Ton Commercial Packaged AC