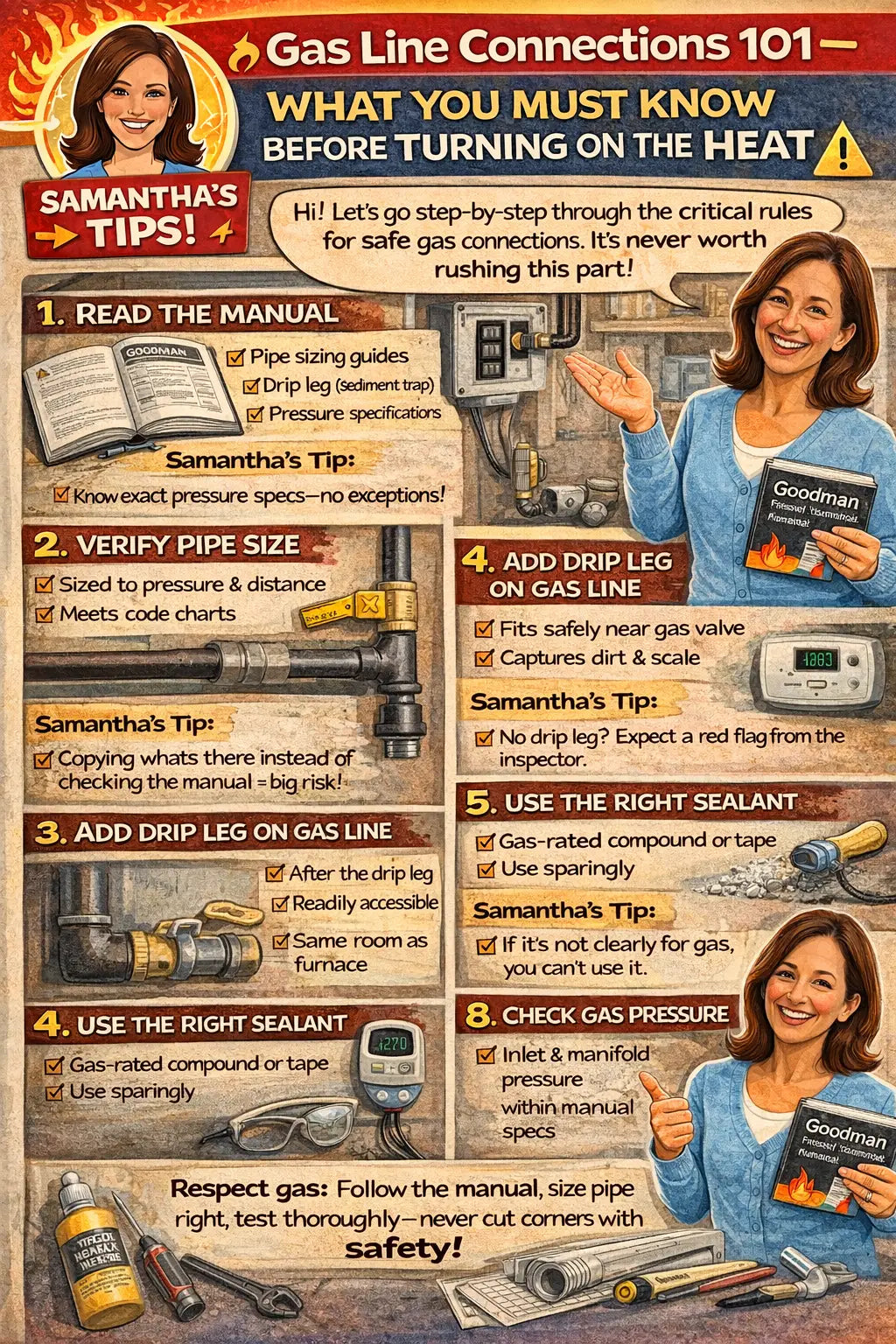

— Samantha’s Straight-Talk Guide to Safe, Code-Smart Gas Hookups

Connecting a gas line to your furnace is the moment when everything becomes real. Up to this point, mistakes are inconvenient. From here on, mistakes can be dangerous.

80,000 BTU 96% AFUE Upflow/Horizontal Two Stage Goodman Gas Furnace - GR9T960804CN

Gas line work isn’t about confidence—it’s about procedure, verification, and restraint. In this guide, I’ll walk you through how technicians think about gas connections, what the codes and manuals actually require, and how to avoid the most common (and costly) errors before you ever open the gas valve.

Bottom line: If you can’t explain why each step exists, pause and reassess. That’s how professionals stay safe.

🧠 Why Gas Line Connections Deserve Extra Respect

Natural gas is efficient and reliable—but only when handled correctly. Improper gas connections can lead to:

-

Fire or explosion risk

-

Carbon monoxide (CO) exposure

-

Delayed ignition or flame rollout

-

Equipment damage and voided warranties

Manufacturers like Goodman, and national standards like the National Fuel Gas Code (NFPA 54), treat gas piping as a life-safety system, not a convenience.

🔗 https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?code=54

📘 Step 1: Start With the Manual (Not the Pipe Wrench)

Before touching any piping, open the installation manual for your exact furnace model. This is non-negotiable.

What the manual specifies:

-

Required inlet gas pressure range

-

Approved fuel type (natural gas vs LP)

-

Pipe sizing guidance

-

Sediment trap (drip leg) requirements

-

Leak-testing expectations

For a typical Goodman high-efficiency furnace, these details are spelled out clearly.

🔗 https://hvacdirect.com/media/pdf/GR9T96-GD9T96-Install-Manual.pdf

👉 Samantha tip:

If your supply gas pressure falls outside the manual’s range, no adjustment downstream will fix it.

🧱🔩 Step 2: Pipe Sizing — Bigger Isn’t Always Better (But Smaller Is Always Worse)

Why pipe size matters

Gas appliances don’t just need gas—they need it at the right volume and pressure under load.

Undersized piping can cause:

-

Weak flames

-

Delayed ignition

-

Short cycling

-

Premature component wear

Oversized piping can:

-

Increase installation cost

-

Create pressure instability in some systems

Pipe sizing depends on:

-

Total BTU load on the line

-

Length of the run

-

Number of fittings and elbows

-

Gas type (NG vs LP)

NFPA 54 provides sizing tables used nationwide.

🔗 https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?code=54

👉 Samantha tip:

Never size gas pipe “by feel” or by copying what was there before—homes change, loads change.

🧯🚫 Step 3: Shutoff Valves — Accessibility Is a Safety Feature

Every furnace must have a manual gas shutoff valve installed:

-

In the same room as the appliance

-

Upstream of the gas valve

-

Readily accessible (not buried behind panels)

Why this matters:

-

Allows quick shutdown during emergencies

-

Required by code

-

Essential for service and inspection

👉 Samantha tip:

If you can’t reach the shutoff without tools or gymnastics, it doesn’t count.

🧪🧱 Step 4: The Sediment Trap (Drip Leg) — Small Part, Big Job

Sediment traps are one of the most skipped—and inspected—gas components.

What a sediment trap does

-

Captures debris, scale, and moisture

-

Protects the gas valve and burners

-

Extends equipment life

Typical requirements:

-

Installed downstream of the shutoff

-

Located before the furnace gas valve

-

Oriented vertically to collect debris

Goodman manuals and NFPA 54 both require sediment traps in most applications.

👉 Samantha tip:

If the inspector sees no drip leg, the inspection often ends right there.

🔧🧴 Step 5: Approved Materials & Thread Sealants

Use only approved piping materials

Commonly accepted (check local code):

-

Black steel pipe

-

Approved CSST (with bonding, if required)

Avoid:

-

Improvised fittings

-

Unrated flexible connectors

-

Old or reused connectors

Thread sealant rules

-

Use gas-rated thread sealant or tape

-

Apply sparingly—never inside the pipe

-

Never mix incompatible sealants

👉 Samantha tip:

If the sealant doesn’t specifically say it’s for gas, don’t use it.

📐🔥 Step 6: Connecting to the Furnace Gas Valve

This is a precision step, not a force step.

Best practices:

-

Support the gas valve with a backup wrench

-

Tighten fittings evenly—no over-torque

-

Maintain proper alignment (no stress on the valve)

Over-tightening can:

-

Crack the gas valve

-

Cause internal damage

-

Lead to delayed leaks

👉 Samantha tip:

If you feel like you’re “cranking” to make it seal, something’s wrong upstream.

🧪👃 Step 7: Leak Testing — The Step You Never Skip

Before turning on the furnace, you must test every joint.

Acceptable methods

-

Approved leak detection solution

-

Electronic gas leak detector

What not to do:

-

Never use an open flame

-

Never rely on smell alone

The CDC emphasizes that gas leaks and CO exposure are serious household hazards.

🔗 https://www.cdc.gov/carbon-monoxide/factsheets/furnace-safety-fact-sheet.html

👉 Samantha tip:

Test under pressure—and test again after the first heat cycle.

🔥📏 Step 8: Gas Pressure Verification (Why “It Lit” Isn’t Enough)

Just because the burners light doesn’t mean the system is safe or correct.

Professionals verify:

-

Inlet gas pressure

-

Manifold pressure

-

Pressure stability during operation

These values must fall within the manufacturer’s specified range.

If you don’t have a manometer—or don’t know how to use one—this is the line where a pro should step in.

👉 Samantha tip:

Gas pressure problems rarely show up immediately—but they always show up eventually.

🧯🛑 Step 9: CO Alarms & Final Safety Checks

Before declaring victory:

-

Confirm CO alarms are installed and working

-

Verify venting is complete and unobstructed

-

Ensure the gas shutoff is labeled and accessible

CO alarms are a last line of defense, not a substitute for proper installation.

🔗 https://www.cdc.gov/carbon-monoxide/factsheets/furnace-safety-fact-sheet.html

🛑 When to Stop and Call a Professional

Stop and get help if:

-

You’re unsure about pipe sizing

-

Gas pressure is outside spec

-

You can’t eliminate a small leak

-

You don’t have proper test equipment

-

Local codes require licensed work

👉 Samantha tip:

Calling a pro at this stage isn’t quitting—it’s protecting your home and family.

🧠 Final Samantha Take: Gas Safety Is About Discipline, Not Speed

Gas line connections reward patience, documentation, and double-checking. They punish shortcuts.

If you:

-

Follow the manual

-

Size piping correctly

-

Install shutoffs and sediment traps

-

Test thoroughly before firing

…you dramatically reduce risk and increase long-term reliability.

Buy this on Amazon at: https://amzn.to/4hJt23t

In the next topic we will know more about: Post-Install Commissioning: Testing Your Furnace Like a Technician