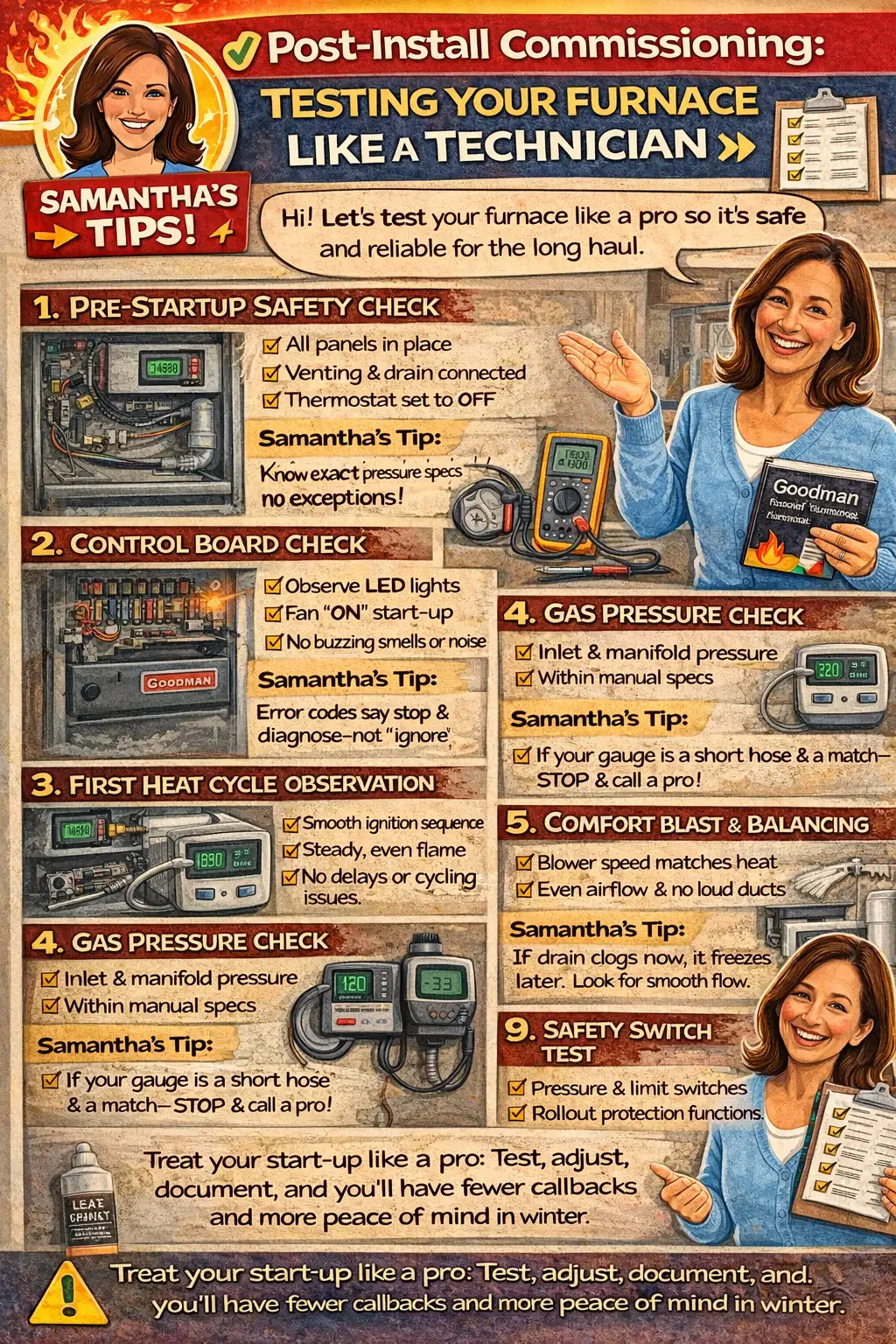

— Samantha’s Step-by-Step Guide to Pro-Level Startup, Safety Checks & Peace of Mind

Installing a furnace is only half the job. The other half—the part that separates a working system from a safe, efficient, long-lasting one—is post-install commissioning.

Commissioning is what technicians do after the furnace is installed but before they walk away. It’s how they confirm the system is operating exactly as the manufacturer intended, the way inspectors expect, and the way your home deserves.

80,000 BTU 96% AFUE Upflow/Horizontal Two Stage Goodman Gas Furnace - GR9T960804CN

In this guide, I’ll walk you through how to test your furnace like a technician, what each test proves, and which steps are absolutely non-negotiable before calling the job “done.”

🧠 What “Commissioning” Really Means (And Why It’s Not Optional)

Commissioning is a structured startup and verification process. It answers five critical questions:

-

Is the furnace safe?

-

Is it operating within manufacturer specs?

-

Is airflow correct and balanced?

-

Are safety controls working and verified?

-

Is performance documented for warranty and inspections?

ENERGY STAR treats commissioning as a best practice for residential HVAC systems because it prevents the most common post-install failures.

🔗 https://www.energystar.gov/sites/default/files/2025-01/National%20HVAC%20Commissioning%20Checklist_Rev%2014.pdf

👉 Samantha tip:

If no one tested it, adjusted it, and documented it—it wasn’t commissioned. It was just installed.

⚠️🔌 Step 1: Pre-Startup Safety Check (Before Powering Anything)

Before you flip a switch, pause.

What technicians verify first

-

Furnace panels fully installed

-

No exposed wiring

-

Gas shutoff accessible

-

Venting fully connected and supported

-

Condensate drain connected and sloped

-

Thermostat set to OFF

This step prevents immediate faults and protects the control board from damage.

👉 Samantha tip:

If you’re tempted to “just see if it turns on,” you’re skipping the most important safety pause.

⚡📟 Step 2: Power-Up & Control Board Check

Once power is restored, technicians don’t rush to heat—they observe.

What to check

-

Control board LED status (normal vs fault codes)

-

Blower response to Fan ON at the thermostat

-

No buzzing, burning smells, or unexpected noises

Most Goodman furnaces use LED flash codes to communicate status. The meanings are listed inside the cabinet or in the manual.

🔗 https://hvacdirect.com/media/pdf/GR9T96-GD9T96-Install-Manual.pdf

👉 Samantha tip:

Error codes at startup mean “stop and diagnose,” not “ignore and hope.”

🔥🧯 Step 3: First Heat Cycle Observation (Sequence of Operation)

This is where technicians slow way down.

A normal heat sequence looks like:

-

Thermostat calls for heat

-

Inducer motor starts

-

Pressure switch closes

-

Igniter warms

-

Gas valve opens

-

Burners light smoothly

-

Flame is steady and even

-

Blower starts after delay

Any deviation matters.

Red flags

-

Delayed ignition

-

Flame rollout

-

Clicking or banging sounds

-

Short cycling

👉 Samantha tip:

A furnace tells you a lot in its first 5 minutes—listen carefully.

📏🔥 Step 4: Gas Pressure Verification (The Pro-Only Step)

Technicians never skip this.

What’s measured

-

Inlet gas pressure

-

Manifold pressure during operation

These values must fall within the manufacturer’s specified range. Being “close” isn’t good enough.

Improper gas pressure can cause:

-

Poor combustion

-

Carbon monoxide risk

-

Reduced efficiency

-

Long-term damage

Gas safety standards are governed nationally by NFPA 54 (Fuel Gas Code).

👉 Samantha tip:

If you don’t have a manometer—or don’t know how to use one—this is where a licensed pro should step in.

🌬️📐 Step 5: Airflow & Temperature Rise Testing

This step protects the heat exchanger, which is the heart of the furnace.

What technicians measure

-

Return air temperature

-

Supply air temperature

-

Temperature rise (difference between the two)

The acceptable range is printed in the furnace manual.

Why it matters

-

Too high → overheating, limit trips, exchanger stress

-

Too low → poor comfort, efficiency loss

Airflow issues are one of the top causes of premature furnace failure.

👉 Samantha tip:

If airflow wasn’t measured, it wasn’t set—it was guessed.

🔊🌬️ Step 6: Blower Operation & Comfort Checks

Now technicians look beyond safety to real-world comfort.

They verify:

-

Blower speed matches heating mode

-

No excessive duct noise

-

Even airflow at registers

-

No vibration or rattling

Poor blower setup doesn’t always fail inspections—but it absolutely fails homeowners.

👉 Samantha tip:

Comfort complaints usually start here, not at the thermostat.

💧❄️ Step 7: Condensate Drain Test (Especially for High-Efficiency Furnaces)

High-efficiency furnaces produce water—sometimes a lot of it.

What to verify

-

Drain slopes continuously

-

No sagging tubing

-

Trap (if used) functions properly

-

No leaks during operation

Blocked or frozen condensate drains are a leading cause of winter shutdowns.

ENERGY STAR includes condensate verification in commissioning checklists.

🔗 https://www.energystar.gov/sites/default/files/2025-01/National%20HVAC%20Commissioning%20Checklist_Rev%2014.pdf

👉 Samantha tip:

If condensate doesn’t flow freely now, it definitely won’t during a cold snap.

🧯🫁 Step 8: Venting & Combustion Safety Verification

Technicians confirm:

-

Vent joints are secure

-

Proper pitch back to furnace

-

Termination is clear outdoors

-

No exhaust spillage

Carbon monoxide safety is the reason this step exists.

The CDC emphasizes proper venting of fuel-burning appliances as critical to preventing CO exposure.

🔗 https://www.cdc.gov/carbon-monoxide/factsheets/furnace-safety-fact-sheet.html

👉 Samantha tip:

CO alarms are backups—not substitutes—for proper venting.

🚨🔍 Step 9: Safety Switch Testing (Yes, They Test Them)

Safety switches are meant to stop operation when something is wrong.

Technicians confirm:

-

Pressure switches open/close correctly

-

Limit switches function

-

Rollout protection is intact

No safety device should ever be bypassed—even “temporarily.”

👉 Samantha tip:

A tripped safety switch is a symptom, not the problem.

🧾📋 Step 10: Documentation & Final Review

Commissioning ends with documentation, not a handshake.

What should be recorded:

-

Gas pressure readings

-

Temperature rise

-

Airflow settings

-

Control board status

-

Date and installer info

This protects:

-

Your warranty

-

Your inspection approval

-

Your future service calls

👉 Samantha tip:

If there’s no paper trail, there’s no proof it was done right.

🛑 When to Stop and Call a Professional

Even confident DIYers should stop if:

-

Gas pressure is out of spec

-

Flames are unstable

-

Safety switches trip repeatedly

-

Error codes persist

-

CO concerns arise

Knowing when to stop is part of doing it right.

🧠 Final Samantha Take: Commissioning Is Where Installations Become Systems

A furnace that turns on is not the same as a furnace that’s commissioned.

When you test:

-

Safety

-

Gas pressure

-

Airflow

-

Controls

-

Drainage

…you’re not being picky—you’re being responsible.

Commissioning is how technicians protect your home, your family, and the furnace itself for years to come.

Buy this on Amazon at: https://amzn.to/4hJt23t

In the next topic we will know more about: DIY vs Pro: When to Install Yourself and When to Call an HVAC Tech