🔧 Introduction: Gas Work Isn’t a Guessing Game — It’s Precision, Discipline, and Respect

Gas line work is the part of HVAC installation that separates true pros from pretenders.

Anyone can set a furnace.

Anyone can glue PVC.

But connecting a gas line to a Goodman 96% AFUE furnace — safely, precisely, and leak-free — requires skill, patience, and a zero-compromise mindset.

I don’t care if it’s:

-

a GM9S960803BN

-

a GMVC960803BN

-

or any other Goodman 96% single- or two-stage furnace

The rules for safe, leak-proof gas line connection never change.

Gas leaks aren’t just dangerous…

they destroy trust, fail inspections, and cause unnecessary callbacks.

My method eliminates all of that.

This is Jake’s Leak-Proof Method — the exact step-by-step approach I’ve perfected over two decades to ensure every Goodman furnace gas line:

-

is clean

-

is correctly sized

-

is properly supported

-

is perfectly aligned

-

is pressure-tested

-

is draft-tested

-

is code-compliant

-

is absolutely leak-free

Let’s get into it.

📏 1. Why Goodman 96% Furnaces Demand Precision on the Gas Line

High-efficiency furnaces have extremely sensitive burners and pressure systems.

Any gas supply irregularity can cause:

-

hard ignition

-

delayed flame rollout

-

high CO production

-

sputtering burners

-

short cycling

-

high manifold pressure

-

nuisance lockouts

Goodman furnaces are engineered beautifully, but they assume you’re giving them a stable, clean, consistent gas supply.

That means YOU — the installer — are responsible for:

-

proper sizing

-

proper torque

-

correct union placement

-

proper sediment trapping

-

correct valve orientation

-

correct sealing

-

pressure verification

A sloppy gas line is a safety hazard.

A perfect gas line is a signature of craftsmanship.

🧰 2. Tools Jake Uses for Leak-Proof Gas Connections

You can’t make a perfect gas connection with bargain-bin tools.

These are my non-negotiables:

✔ Two Adjustable Wrenches (10" & 12")

Never rotate one side only — always counterforce.

✔ Pipe Thread Sealant (Gas-Rated)

Tape alone is NOT acceptable on tapered pipe threads.

Use both sealant and reinforced tape.

External verified link:

• Rectorseal #5 Technical Data

https://rectorseal.com

✔ Yellow Gas Teflon Tape (PTFE)

Only yellow tape is gas-rated.

✔ Pipe Cutter or Threaded Nipple Assortment

No hack-saw burrs. Ever.

✔ Digital Manometer

To verify manifold pressure to Goodman spec.

External verified link:

• Fieldpiece Manometer Specifications

https://www.fieldpiece.com

✔ Bubble Leak Detector

Soapy water isn’t enough.

Use a professional formula.

External verified link:

• Oatey Gas Leak Detector

https://www.oatey.com

✔ Gas Pressure Test Gauge (0–30" WC)

To test supply pressure during operation.

🧱 3. Jake’s Rule: The Gas Line Must Never Put Stress on the Furnace Valve

Most installers get this wrong.

They run the black iron or flex line into the furnace’s gas valve at an angle or with tension, causing:

-

valve body stress

-

premature valve failure

-

leaks over time

-

rattling under burner startup

Jake’s Rule:

The gas line must enter the furnace gas valve perfectly straight, perfectly level, and without tension.

This means:

-

no forced alignment

-

no “pulling” the gas line into place

-

no weight hanging off the valve

-

no rigid pipe directly connected without proper support

A stressed gas valve is a future leak.

🔩 4. Sizing the Gas Line: The Forgotten Step Most Installers Skip

A Goodman 96% furnace has specific input BTUs — typically 80,000 BTU on the GR9S/GM9S960803BN — which means your gas supply must be able to handle:

-

total BTU load

-

line length

-

number of fittings

-

pressure drop

Undersized lines cause:

-

ignition delay

-

weak flame

-

burner flutter

-

high CO levels

-

furnace shutdowns

External verified link:

• NFPA 54 – Gas Piping Sizing Tables

https://www.nfpa.org

Jake’s rule:

**Minimum ½” line to furnace

¾” recommended for long runs or multiple appliances.**

When in doubt:

Go bigger. Never smaller.

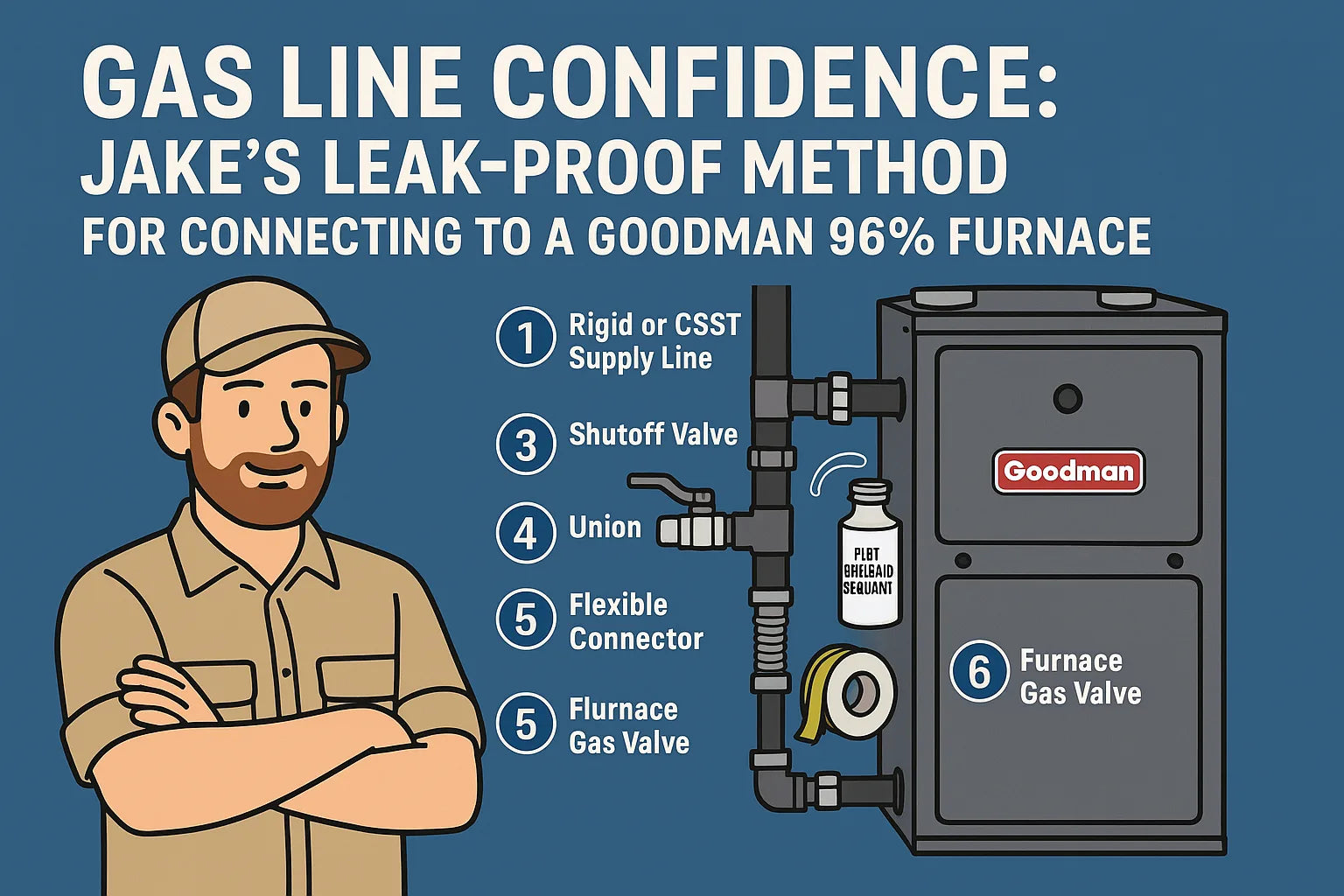

🧲 5. The Components of a Proper Leak-Proof Furnace Gas Connection

Here’s the order, exactly:

🟩 1. Rigid Black Iron or CSST Supply Line

Rigid pipe is ideal.

CSST must be bonded.

🟦 2. Drip Leg / Sediment Trap

This protects the gas valve from debris.

Must be installed before the furnace’s gas valve.

Goodman requires this. Period.

External verified link:

• Goodman Installation Manuals — Sediment Trap Requirements

https://www.goodmanmfg.com

🟧 3. Shutoff Valve (¼-turn ball valve, gas-rated)

Must be:

-

accessible

-

in the same room

-

upstream of the union

🟨 4. Union

Allows service and valve replacement without cutting.

Never install the union:

-

directly on the valve

-

inside the furnace cabinet

-

under tension

🟥 5. Flexible Connector (Approved Gas Flex)

Not required on all installs, but highly recommended for vibration isolation.

Never use appliance-grade flex inside a furnace cabinet.

🟪 6. Furnace Gas Valve Connection

Threaded male connector into the valve.

Proper torque:

Snug + ¼ turn — no more.

🔧 6. Jake’s Leak-Proof Threading Method (The Secret Sauce)

This is the part that eliminates 99% of leaks.

I use a three-layer technique:

✔ Step 1 — Clean Threads

No oil

No debris

No metal shavings

✔ Step 2 — Wrap Yellow Gas Tape

Wrap clockwise (right-hand thread direction).

3–4 wraps maximum.

✔ Step 3 — Brush on Pipe Thread Sealant

Apply a thin, even coat.

Most installers use too much.

Excess sealant creates debris inside the gas valve.

✔ Step 4 — Hand Thread First

If it doesn’t spin three full turns by hand, back off and restart.

✔ Step 5 — Tighten with Counterforce

Use two wrenches:

-

Wrench #1 stabilizes the pipe or valve

-

Wrench #2 tightens the fitting

This prevents valve twisting — a major cause of leaks.

🔥 7. Pressure Testing — Jake’s Gold Standard

After the line is assembled:

🧪 A. Static Pressure Test (No Furnace Running)

Check supply pressure with a gauge.

Natural gas should be:

5–10” WC (varies by utility)

Propane should be:

10–14” WC

🧪 B. Dynamic Pressure Test (Furnace Running)

This tells you the REAL story.

Turn on:

-

furnace

-

water heater

-

gas dryer

-

stove burners

This simulates max draw.

Watch for drops below:

-

4.5” WC natural gas

-

10” WC propane

If pressure drops, the line is undersized.

🧪 C. Manifold Pressure Test (At Furnace Gas Valve)

Adjust to Goodman spec:

-

Natural gas: 3.5” WC

-

Propane: 10” WC

External verified link:

• Goodman Furnace Manifold Pressure Specs

https://www.goodmanmfg.com

This ensures clean, stable flame.

🔍 8. Leak Testing: Jake’s Two-Stage Verification

Gas leaks hide.

Here’s how you find ALL of them.

1️⃣ Stage One — Bubble Solution Test

Apply professionally formulated gas leak detector.

Look for:

-

tiny pinhole bubbles

-

constant foaming

-

growing clusters

Even ONE bubble = leak.

2️⃣ Stage Two — 5-Minute Observation Test

Many leaks show up slowly.

Set a timer.

Watch the joint.

If you see ANY bubble forming:

Disassemble and redo the connection.

No exceptions.

🎯 9. Common Gas Line Installation Mistakes (Jake’s No-Fly List)

These mistakes keep me in business — because I get called to fix them.

❌ Using only Teflon tape

Tape + sealant is the correct method.

❌ Over-tightening

Cracks fittings.

Stresses valve.

❌ Under-tightening

Causes slow leaks.

❌ No sediment trap

Debris kills valves.

❌ Bending flex line too tightly

Kinks reduce flow.

❌ Gas line entering the valve at an angle

Creates long-term leaks.

❌ Union installed inside the cabinet

Illegal in most jurisdictions.

❌ Gas line touching sharp metal

Vibration rub-through.

❌ Line not supported

Weight pulls on valve.

❌ Wrong size gas line

Produces burner instability.

🔒 10. Jake’s 7-Point Reliability Check Before Closing the Furnace

This is my final safety test.

✔ 1. Gas valve perfectly aligned

✔ 2. No stress on the valve body

✔ 3. Shutoff valve easily accessible

✔ 4. Sediment trap installed correctly

✔ 5. All joints bubble-tested and dry

✔ 6. Manifold pressure adjusted

✔ 7. Burner ignition clean and quiet

When these 7 are perfect, the gas line is perfect.

🏁 Conclusion: Gas Line Confidence Comes From Discipline, Not Luck

A good HVAC installer makes clean sheet metal.

A great HVAC installer makes clean gas lines.

But a master-level installer — the kind of tech homeowners trust and inspectors respect — understands that gas work is:

-

precise

-

deliberate

-

methodical

-

tested

-

verified

-

documented

-

bulletproof

This is Jake’s Leak-Proof Method.

Follow it, and you’ll never fear a gas inspection — or a callback — again.

Your furnace will ignite smoothly.

Your burners will stay clean.

Your exhaust will stay stable.

And your Goodman 96% will run the way it was engineered to run.

Safe.

Efficient.

Confident.

Leak-free.

Buy this on Amazon at: https://amzn.to/48HGh2g

In the next topic we will know more about: The Condensate Equation: How Jake Routes Lines to Avoid Freeze-Ups, Backflow, and Nuisance Shutdowns