🔧 Introduction: Why Condensate Routing Is the Silent Killer of 96% Furnaces

High-efficiency furnaces like the Goodman 96% AFUE series (GM9S, GMVC, GC9) extract so much heat that the exhaust cools and condenses into water.

80,000 BTU 96% AFUE Upflow/Horizontal Single Stage Goodman Gas Furnace - GR9S960803BN

That water — the condensate — must be removed without interruption.

Even a tiny mistake in routing can turn into:

-

furnace shutdowns

-

pressure-switch trips

-

inducer flooding

-

coil pan overflow

-

drain pan fill-ups

-

frozen lines

-

sewer gas smells

-

corrosion inside the cabinet

-

water damage to floors or platforms

Most installers think condensate routing is simple because it's “just water.”

But on a 96% furnace, condensate is the heartbeat that keeps the whole system running.

I’ve seen perfect installs ruined by a bad drain line.

I’ve seen $8,000 systems shut down because of one 90° elbow installed wrong.

I’ve seen frozen lines destroy heat exchangers.

So I built a method — a formula, really — for routing condensate lines on Goodman furnaces that never freeze, never backflow, and never cause a single shutdown.

I call it The Condensate Equation.

Let’s break it down.

💧 1. The Science Behind Condensate — And Why 96% Furnaces Hate Bad Drains

A Goodman 96% furnace generates ½ to 1 gallon of condensate per hour during heavy operation.

This water:

-

is acidic (pH 3–5)

-

contains dissolved exhaust gases

-

carries heat exchanger byproducts

-

must flow downhill continuously

If it stalls anywhere in the system, you get:

-

gurgling

-

inducer blockage

-

pressure switch faults

-

premature shutdown

-

corrosion

And the worst part?

Condensate failures often mimic electrical, pressure, or ignition issues.

So techs misdiagnose it constantly.

Here’s the truth:

Most intermittent 96% furnace problems are actually hidden condensate problems.

When you learn the condensate equation, you solve 90% of “mystery” callbacks instantly.

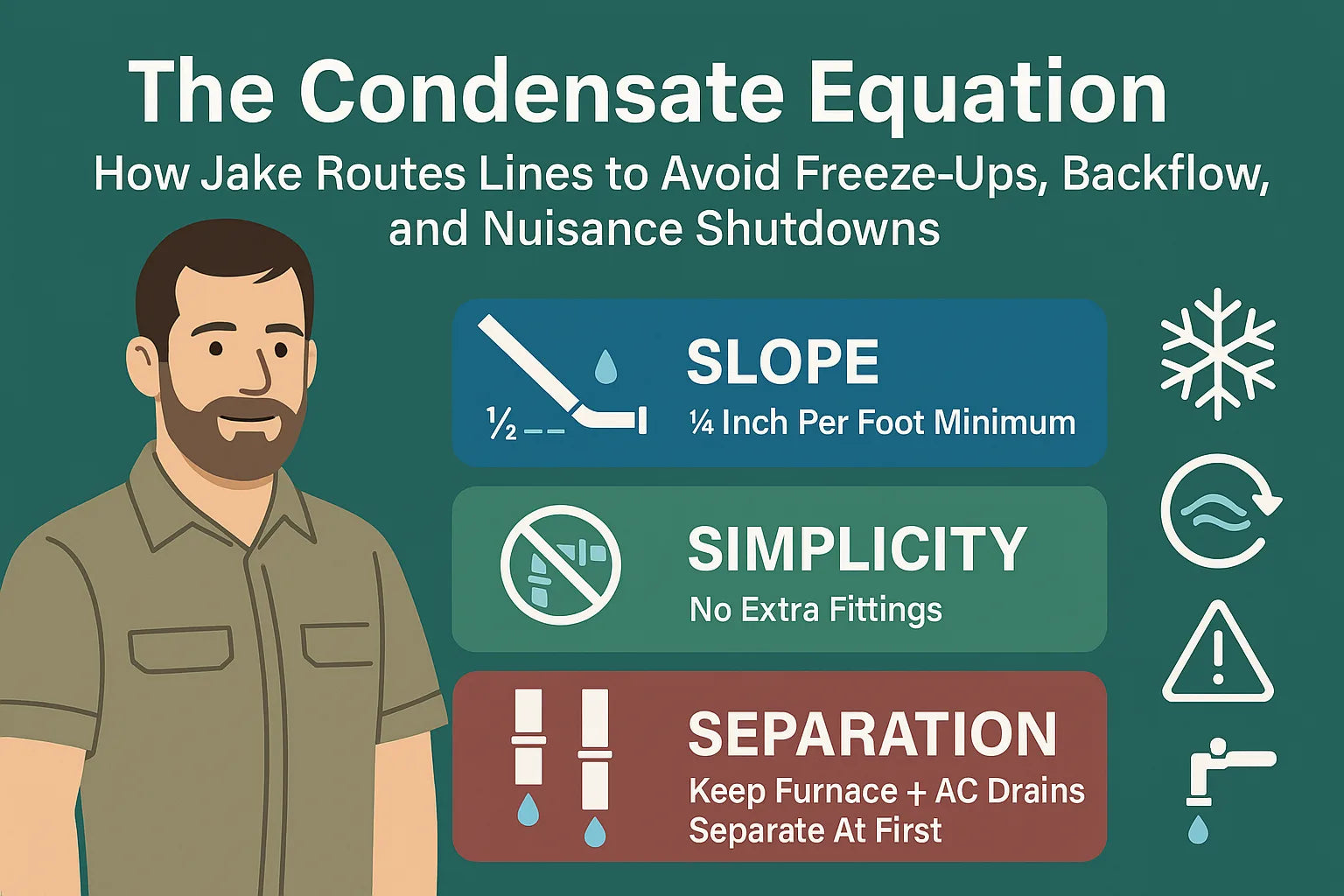

📐 2. Jake’s Condensate Equation: The Three Rules That Prevent 99% of Failures

After thousands of installs, I built this formula:

Slope + Simplicity + Separation = Zero Shutdowns

Let’s break it down.

🟦 RULE 1 — SLOPE (¼ Inch Per Foot Minimum)

Slope is the heart of the equation.

Horizontal runs longer than 3 feet must be sloped ¼ inch per foot, per code.

External verified link:

• International Plumbing Code – Condensate Disposal Slope Requirements

https://codes.iccsafe.org

If slope is too low:

-

water sits

-

algae grows

-

freezing starts

-

vacuum lock happens

-

inducer floods

When in doubt, increase slope.

Water never complains about moving too fast.

🟩 RULE 2 — SIMPLICITY (No Extra Fittings)

Every unnecessary elbow increases:

-

clog points

-

freeze points

-

friction

-

chances of backflow

Jake’s Rule:

One 90° elbow per 10 feet.

No more than three total in the entire run.

Use 45° fittings whenever possible.

🟥 RULE 3 — SEPARATION (Keep Furnace + AC Drains Separate At First)

Never combine the AC drain and furnace drain inside the cabinet or at the pan.

They must stay separate until:

-

after their traps

-

after their flow stabilizes

This prevents:

-

condenser coil backflow into furnace

-

inducer suction pulling AC water backward

-

shared blockage failures

AC drain → its own trap

Furnace drain → its own trap

Then combine downstream.

🧊 3. Freeze-Up Prevention — Jake’s Cold Climate Rules

If you install furnaces in cold climates, memorize this section like gospel.

❄️ Rule 1 — No Horizontal Runs in Unconditioned Spaces

Attics, crawlspaces, garages — forget it.

Run drains vertically as fast as possible until indoors.

❄️ Rule 2 — Insulation Is Mandatory

Use ½" wall foam pipe insulation.

Tape every seam.

External verified link:

• Armacell Pipe Insulation Specs

https://www.armacell.us

❄️ Rule 3 — No Low Spots, No Bellies, No Dips

These freeze first.

Support drains every 3–4 feet to prevent sagging.

❄️ Rule 4 — Heat Tape for Extreme Climates

If ambient temps go below 20°F, use electric heat tape rated for PVC.

❄️ Rule 5 — Never Let Drains Exit the Home Until They’re Flowing Warm

Every inch of exposed drain outside is a freeze point.

Route drains through:

-

conditioned space

-

insulated chase

-

basement

-

utility room

Then terminate.

🔄 4. The Furnace Trap: The Most Misunderstood Component on the Install

A Goodman 96% furnace has an external removable trap.

This trap is essential because:

-

the inducer creates negative pressure

-

without a trap, it will suck air through the drain

-

this air breaks condensate flow

-

causing gurgling and shutdowns

Jake’s Rules for the Trap:

✔ Never modify the factory trap

✔ Never install it backward

✔ Never add a second trap upstream

✔ Never “double trap” a furnace

✔ Trap must be accessible

✔ Trap must be removable

✔ Trap must be cleanable

Adding your own trap before the furnace’s built-in trap is a guaranteed failure.

🧱 5. Jake’s 7-Step Perfect Condensate Routing Method

This is the exact process I use on every Goodman 96% furnace.

🟦 STEP 1 — Connect the Furnace Drain with Straight, Vertical Drop

Directly off the furnace port:

-

6–12 inches vertical

-

no elbows

-

no dips

Let gravity win early.

🟧 STEP 2 — Install the Factory Trap at the Correct Height

Trap should sit:

-

level

-

accessible

-

below furnace drain outlet

Never let the trap touch the floor or cabinet wall.

🟩 STEP 3 — Transition to ¾” PVC or Vinyl Tubing

Rigid PVC = best for long runs

Vinyl tubing = best for short, flexible paths

Always use barbed fittings for tubing.

🟥 STEP 4 — Route the Line With Continuous Slope

Minimum ¼ inch per foot

Maximum 1 inch per foot (to prevent noise)

Use:

-

pipe hangers

-

clamps

-

nylon straps

Support every 3–4 feet.

🟪 STEP 5 — Avoid Every Unnecessary Elbow

Replace 90° elbows with:

-

two 45° bends

-

flexible radius curves

-

straight drops

🟫 STEP 6 — Keep AC Drain Separate Until After Both Traps

AC trapped drain

Furnace trapped drain

→ Tee together downstream

→ Terminate to floor drain or pump

Never merge untrapped drains.

🟨 STEP 7 — Terminate to One of Jake’s Four Approved Options

✔ Floor Drain

Best option. Never fails.

✔ Condensate Pump

For basements or long runs.

Must be mounted above pump inlet height.

External verified link:

• Little Giant Condensate Pump Specs

https://www.littlegiant.com

✔ Laundry Standpipe

Code-permitting.

✔ Indirect Drain With Air Gap

Where plumbing code requires it.

Never terminate into:

-

crawlspace

-

yard

-

flower bed

-

gutter

-

open sump pits

These freeze instantly in winter.

🔍 6. Backflow Prevention — The Hidden Failure Most Installers Never Check

Backflow happens when:

-

AC drain overwhelms furnace drain

-

sewer line backs up

-

condensate pump stalls

-

traps dry out

-

negative pressure pulls backward

Jake’s Backflow Shields:

✔ 1. Positive slope

✔ 2. Independent traps

✔ 3. No interior merging

✔ 4. Correct termination height

✔ 5. Trap priming

✔ 6. Proper venting near standpipes

Master these six, and your furnace never sees backflow.

🧪 7. Jake’s Testing & Commissioning Process (Don’t Skip This)

A drain line isn’t “done” until it passes all five of these tests.

TEST 1 — Gravity Flow Test

Pour 8–12 oz. of water through the trap.

It must:

-

evacuate immediately

-

without pulsing

-

without airlock

TEST 2 — Inducer Seal Test

Run the furnace on high heat.

Listen for:

-

gurgling

-

sucking

-

whistling

These indicate improper trap height or slope.

TEST 3 — Furnace Off / Slow Drain Test

Turn furnace off.

Observe for standing water.

Standing water = slope error.

TEST 4 — Freeze Simulation (Cold Climate Only)

Touch insulation.

Feel for cold spots.

Check for areas of sagging.

This prevents mid-winter emergencies.

TEST 5 — Condensate Pump Power Cycle

If using a pump:

-

unplug

-

replug

-

run furnace

Ensure pump restarts and drains properly.

🚨 8. Common Condensate Routing Mistakes (Jake’s “Never Do This” List)

I’ve fixed hundreds of bad installs.

Here are the red flags I look for immediately.

❌ TRAP INSTALLED ABOVE THE FURNACE DRAIN

Will cause water to backflow.

❌ DOUBLE TRAPPING

Creates vacuum lock.

❌ NO TRAP AT ALL

Inducer sucks air into drain → gurgling + shutdowns.

❌ HORIZONTAL RUNS IN COLD SPACES

Freeze city.

❌ DRAIN LINE TOUCHING HOT FLUE

Melts tubing.

❌ MERGING AC AND FURNACE DRAINS TOO EARLY

Causes cross-backflow.

❌ SAGGING LINES

Create micro-freeze points.

❌ FLEX LINE KINKED

Instant shutdown.

❌ TERMINATING OUTSIDE IN WINTER CLIMATES

Everything freezes.

❌ 90° ELBOW AT THE TRAP OUTLET

Creates vortexing.

📦 9. Jake’s Condensate Materials List (Bulletproof Components Only)

✔ ¾” PVC pipe

✔ 45° elbows

✔ Clear vinyl tubing (short runs only)

✔ ½” foam insulation

✔ PVC cement & primer

✔ Nylon pipe straps

✔ Goodman OEM trap assembly

✔ Condensate pump (Little Giant)

✔ Silicone or mastic for sealing cabinet penetrations

Cheap materials = expensive callbacks.

📘 Conclusion: The Condensate Equation Is the Backbone of a Zero-Callback Goodman Install

You can install the perfect:

-

plenum

-

venting

-

gas line

-

thermostat

-

duct transitions

…but if your condensate line is wrong?

Your entire system fails.

Proper condensate routing is:

-

physics

-

code

-

safety

-

craftsmanship

-

reliability

-

longevity

Jake’s Condensate Equation:

Slope + Simplicity + Separation = Zero Shutdowns

This is how you eliminate freeze-ups.

This is how you eliminate backflow.

This is how you eliminate the most annoying, repeating, and costly callbacks in HVAC.

Master the drain line —

and you master the 96% furnace.

Buy this on Amazon at: https://amzn.to/48HGh2g

In the next topic we will know more about: Return Air Reality Check: Jake’s Installation Audit That Prevents High Static Before the First Start-Up