🔧 Introduction: Venting Isn’t an Afterthought — It’s the Lifeline of the Furnace

The venting system is the lungs of a modern furnace.

It exhausts combustion gases, pulls in combustion air (if sealed), protects the heat exchanger, maintains draft, and keeps efficiency where it belongs.

Yet every week I see installers treat venting like a piece of leftover PVC:

-

too many elbows

-

too-long runs

-

bad transitions

-

flat sections

-

backwards slope

-

unsupported spans

-

forced offsets

-

unnecessary loops to “make it fit”

Modern high-efficiency units — especially 90%+ condensing furnaces like the Goodman GM9S/GMVC/GC9 models — are incredibly sensitive to vent design.

When your venting is sloppy, your furnace:

-

cycles harder

-

drafts slower

-

hits pressure switch lockouts

-

builds condensate in the wrong places

-

runs louder

-

runs less efficiently

-

shortens the inducer motor’s life

-

can even backflow exhaust

One simple rule fixes almost all of this:

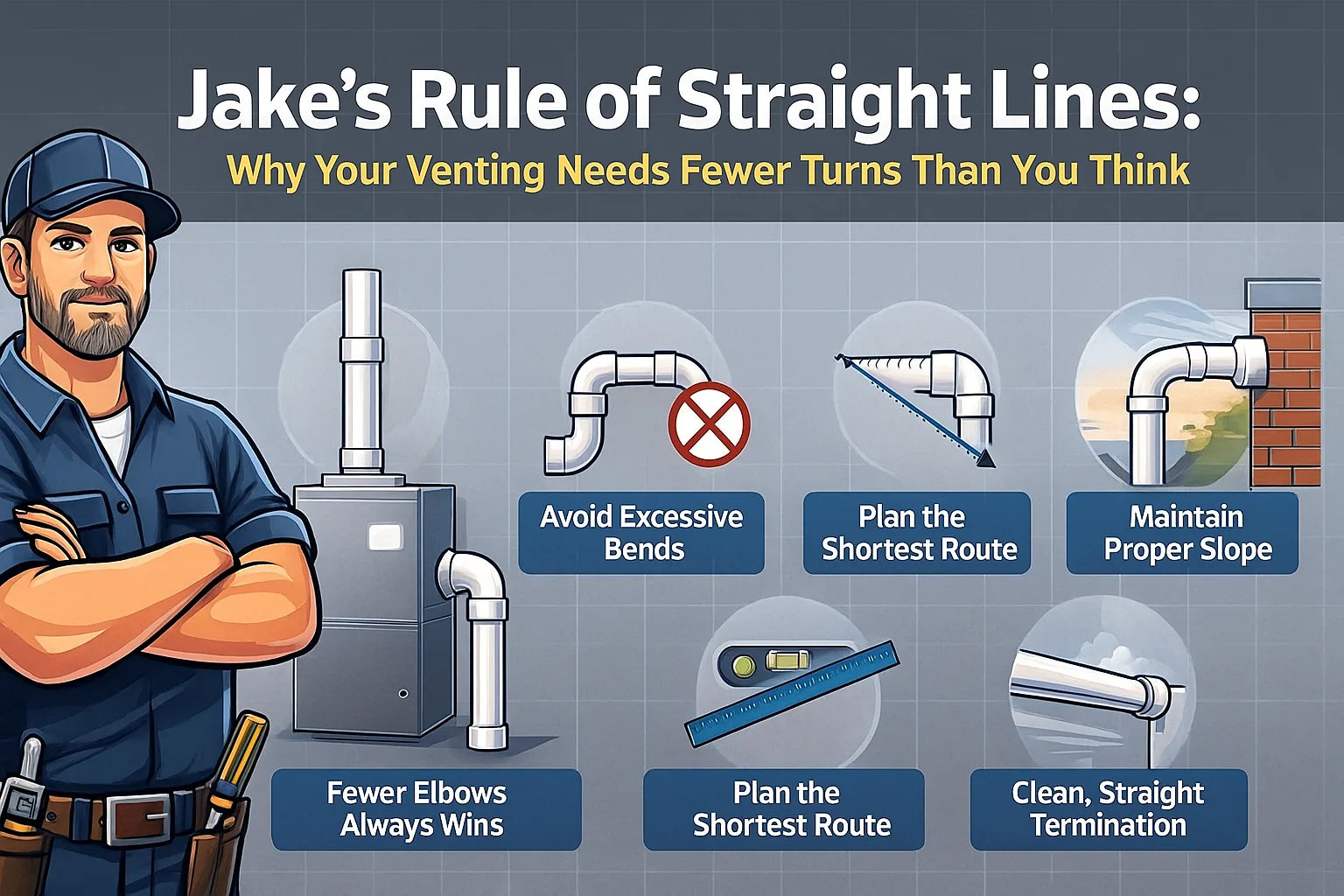

Jake’s Rule of Straight Lines:

If you can run it straight, you run it straight.

Every turn you eliminate buys you performance, silence, and longevity.

This article breaks down why venting should be straight, how every elbow hurts you, and the exact method I use to design venting that never causes callbacks.

80,000 BTU 96% AFUE Upflow/Horizontal Single Stage Goodman Gas Furnace - GR9S960803BN

🧭 1. The Physics Behind Jake’s Rule (Why Straight Lines Always Win)

Before you even touch a stick of PVC, understand this:

Every elbow = resistance.

Every elbow disrupts smooth airflow and forces the inducer to work harder.

That means:

-

more amperage draw

-

more noise

-

more heat

-

more vibration

-

more long-term wear

A 90° elbow is equivalent to 5–10 feet of pipe

Depending on model and manufacturer.

External verified link:

• Engineering Toolbox – Pipe Fittings Equivalent Length

https://www.engineeringtoolbox.com/

When you add two 90° turns at the furnace and two more at the termination, you may have added 40+ equivalent feet without realizing it.

A lot of guys think they have a “20-foot run.”

In reality, it’s behaving like 60 feet.

And many furnaces max out around 50–90 foot equivalent runs depending on:

-

diameter

-

climate

-

firing rate

-

venting configuration

-

termination type

So yes… elbows matter.

🛠️ 2. Why Installers Add Too Many Turns (and Why They’re Wrong)

Most guys add elbows because:

❌ They’re trying to work around clutter

(“The water heater’s in the way.”)

❌ They follow the existing vent path from the old furnace

(Which was wrong too.)

❌ They try to hug walls to “look cleaner”

(Straight lines look cleaner.)

❌ They don’t plan the run before gluing

(Every apprentice mistake I’ve seen.)

❌ They’re afraid to remove old unnecessary piping

(Don’t build around trash — remove it.)

❌ They don’t know the equivalent length chart

(The pressure switch does.)

What they should be doing is designing the vent BEFORE moving the furnace into place.

That’s where Jake’s Straight Line Method comes in.

📏 3. Jake’s Straight Line Method (My Field-Proven Blueprint)

Here is the exact process I follow on every Goodman 90%+ install.

🟦 Step 1 — Start at the Furnace Collar, Not the Wall

Most installers plan venting backward:

Wall ➝ Furnace

Wrong.

Start at the furnace’s outlet and imagine the shortest, straightest path to daylight.

The furnace location should support the venting — not the other way around.

🟦 Step 2 — The First 18 Inches Must Be Straight

This is non-negotiable.

A straight initial rise:

-

stabilizes draft

-

gives the inducer a clean launch

-

prevents pressure switch flutter

-

prevents condensate from sloshing back

Never elbow immediately out of the furnace.

🟦 Step 3 — Run Toward the Terminal in the Straightest Line Possible

Ask yourself:

“What path eliminates the most elbows?”

Choose THAT path, not the convenience path.

🟦 Step 4 — If a Turn Is Required, Make It a Long Sweep 90°

A long sweep 90° acts closer to a gentle redirect than an abrupt “dead stop then turn.”

Long sweeps drastically lower equivalent length.

External verified link:

• PVC Fittings – ASTM Standards

https://www.astm.org

🟦 Step 5 — Maintain Continuous Slope, Always Away From the Furnace

Slope requirements for venting:

-

Exhaust: ¼" per foot slope toward furnace (for condensing furnaces)

-

Intake: flat or slight slope away from termination

Follow manufacturer instructions for your specific Goodman model.

External verified link:

• Goodman Installation & Venting Manuals

https://www.goodmanmfg.com

🟦 Step 6 — Terminate Clean and Straight Outdoors

No weird offsets.

No excessive elbows to “look centered.”

The straighter the termination, the smoother the draft.

🌀 4. What Too Many Turns Actually Does to a Furnace

Let’s talk real consequences.

❗ 1. It Overworks the Inducer Motor

More static pressure = shorter life span.

❗ 2. It Causes Pressure Switch Trips

Every tech has been burned by this.

❗ 3. It Increases Furnace Noise

Air turns cause turbulence → turbulence causes rumble.

❗ 4. It Traps Condensate

Bad slope + too many elbows = internal flooding.

❗ 5. It Lowers Efficiency

The furnace wastes energy fighting airflow resistance.

❗ 6. It Shortens Heat Exchanger Life

Restricted exhaust = hotter furnace core.

❗ 7. It Can Cause Improper Combustion

Yes, your venting affects flame stability.

External verified link:

• NFPA 54 – National Fuel Gas Code

https://www.nfpa.org

🏗️ 5. The Four Elbows That Kill Most Installs

Jake’s red-flag elbows:

🔴 Elbow #1 — Immediately at the Furnace Outlet

This creates:

-

draft stall

-

turbulence

-

water pooling

-

noise

-

pressure switch flutter

I call this “The Lazy Elbow.”

🔴 Elbow #2 — Two 90s in a Row to Make a U-shape

Installers do this to “jump obstacles.”

Bad idea.

Use:

-

a 45° pair

-

a long sweep

-

or reroute entirely

🔴 Elbow #3 — Horizontal-to-Vertical Tight Turn

This creates a water trap.

🔴 Elbow #4 — The Decorative Termination Elbow

Installers sometimes offset the termination outside just to “make it look symmetrical.”

Symmetry is fine…

but not at the expense of three extra elbows.

🔍 6. Exceptions to Jake’s Rule — When a Turn Is Actually Necessary

Very rarely, a turn helps you.

⚪ 1. Avoiding a Gas Line or Electrical Conduit

Safety > straight line.

⚪ 2. Avoiding structural beams or joists

Don’t weaken structural members.

⚪ 3. To maintain proper slope

If slope is impossible without a turn, you must adjust.

⚪ 4. Termination clearance requirements

Code and manufacturer spacing comes first.

External verified link:

• IRC Mechanical Vent Termination Rules

https://codes.iccsafe.org

🧰 7. Jake’s Venting Materials: What I Use and Why

✔ 2" or 3" Schedule 40 PVC or CPVC

Strong, rigid, straight.

✔ Long Sweep 90° Elbows

Lower friction.

✔ Two-Hole Pipe Straps Every 3–4 Feet

Prevents sag, which creates water traps.

✔ Primer + High-Quality PVC Cement

Avoids leaks and weak joints.

✔ Stainless Outside Termination Kits

Prevents warping in sun.

🧪 8. Testing Your Venting Like Jake (Commissioning Checklist)

Any tech can glue pipe.

A pro tests it.

🔵 1. Manometer Pressure Testing

Ensure pressure switch readings match manufacturer specs.

🔵 2. Water Level Test (Condensate Behavior)

Pour water into the drain connection — watch the flow.

🔵 3. Smoke Test

Ensure draft pulls smoke cleanly through exhaust.

🔵 4. Inducer Sound Test

A straight vent sounds:

-

smooth

-

quiet

-

low vibration

Too many elbows = turbulence roar.

🔵 5. Outdoor Termination Inspection

Verify exhaust/intake are not cross-contaminating.

🧊 9. Cold Climate Venting — Why Straight Lines Matter Even More

In cold climates:

-

condensate thickens

-

elbows freeze faster

-

exhaust vapor crystallizes

-

intakes frost over

-

warm exhaust cools quicker

Straight pipe resists freeze-ups better than complex runs.

External verified link:

• Energy Star – Cold Climate Furnace Guidance

https://www.energystar.gov

🛑 10. The Number One Mistake: Venting Before Furnace Positioning

I see this constantly…

Installers position the furnace based on the vent path instead of designing venting around the furnace’s location.

NO.

The furnace must be:

-

centered under the coil

-

aligned with the plenum

-

aligned with the return

Then you choose the vent path that keeps the run straight.

Not the other way around.

✔️ 11. Jake’s Final Straight Line Checklist (Print This)

✔ Straight rise out of the furnace (18 inches minimum)

✔ Long-sweep elbows only

✔ Eliminate every elbow possible

✔ Maintain continuous slope (¼” per foot)

✔ Avoid double-90 “U-turns”

✔ Avoid elbow-out-of-the-furnace

✔ Use two-hole straps to prevent sag

✔ Keep intake/exhaust separated and level

✔ Keep termination straight and obstruction-free

✔ Verify equivalent length is within Goodman specs

Follow this list, and your venting will never cause a callback.

🔥 Conclusion: Straight Venting = Safe, Quiet, Efficient Heating

When venting is done right, the furnace practically whispers.

Draft is smooth.

Condensate drains perfectly.

The pressure switch never complains.

The inducer lives forever.

The heat exchanger stays healthy.

When venting is done wrong, every part of the furnace suffers.

Jake’s Rule of Straight Lines is simple:

If you think you need three elbows, you probably need one.

If you think you need two, you might need zero.

Straight lines win every time.

Master venting, and you master system performance.

Buy this on Amazon at: https://amzn.to/48HGh2g

In the next topic we will know more about: Gas Line Confidence: Jake’s Leak-Proof Method for Connecting to a Goodman 96% Furnace