When most homeowners think about their furnace, they picture the flame, thermostat, or warm air blowing from the vents. But one of the most critical — and overlooked — parts of any heating system is the venting system.

Without proper venting, your furnace can’t safely or efficiently remove combustion gases. That’s why the type of vent pipe — PVC or metal — matters more than you might realize.

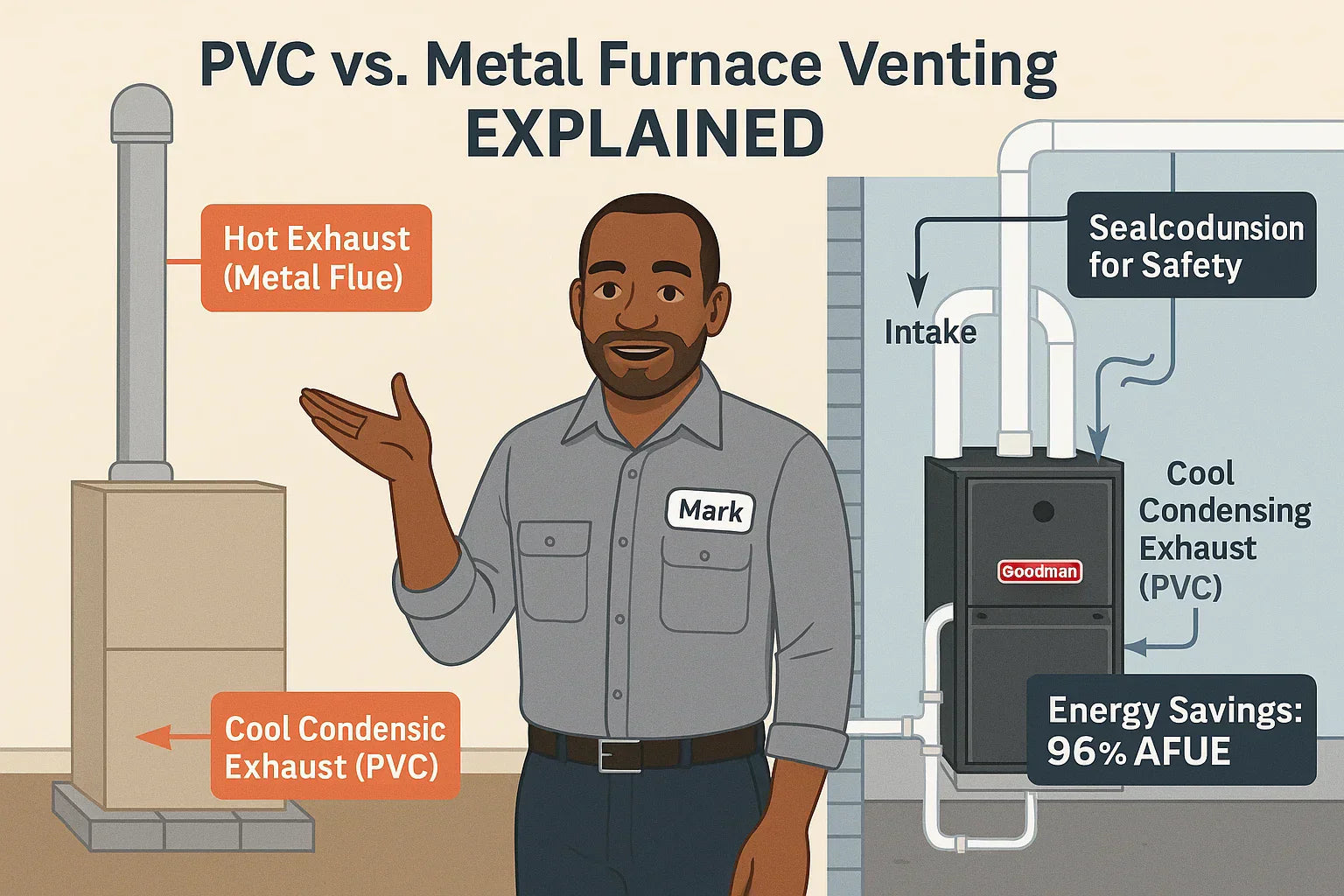

For homeowners like Mark, who recently upgraded to a Goodman 96% AFUE Two-Stage Furnace (Model GRVT961005DN), understanding venting was key to getting his installation right.

“I’d always had a metal flue through the roof. My new Goodman uses PVC pipes through the side wall — I didn’t know why until the installer explained how it works.”

In this guide, we’ll explain how furnace venting works, the difference between PVC and metal flues, and why Goodman’s high-efficiency furnaces are engineered for today’s advanced PVC venting systems.

🧭 1. Why Furnace Venting Matters More Than You Think

Every gas furnace produces heat by burning natural gas or propane. That combustion creates two things:

-

Warm air for your home, and

-

Byproducts like carbon dioxide, water vapor, and trace carbon monoxide.

Those byproducts must be vented safely outdoors. Venting also draws in oxygen for combustion and maintains pressure inside the heat exchanger.

If venting fails — even partially — you risk dangerous exhaust gases entering your home or damaging furnace components.

In short:

-

Venting = safety

-

Venting = efficiency

-

Venting = comfort

That’s why Goodman engineers their furnaces — including the GRVT961005DN — with sealed, efficient venting systems that match the furnace’s design and AFUE rating.

🌬️ 2. The Basics: What a Furnace Venting System Does

All gas furnaces handle combustion air and exhaust in three steps:

-

Intake Air – Fresh air enters the burner assembly to mix with gas.

-

Combustion & Heat Exchange – Gas ignites, heating metal coils that transfer heat to your home’s air.

-

Exhaust Venting – Remaining combustion gases are pushed out through a flue.

The difference between venting systems — metal vs. PVC — comes down to how efficiently a furnace burns fuel. Higher-efficiency furnaces create cooler exhaust, allowing new materials and venting methods.

The U.S. Department of Energy classifies furnaces into categories based on how they handle exhaust:

-

Category I: Standard (non-condensing, 80% AFUE, metal vent)

-

Category IV: Condensing (90–98% AFUE, PVC vent)

Goodman’s GRVT961005DN is a Category IV furnace — a sealed, fan-assisted, condensing unit that uses PVC venting for top-tier efficiency.

🔩 3. Metal Flue Systems: The Classic Choice for Older Furnaces

For decades, traditional gas furnaces used metal vent pipes, often galvanized steel or aluminum, connected to a chimney. These systems work through natural draft, where hot exhaust gases rise up the flue and exit through the roof.

🔧 How Metal Flues Work

-

Hot exhaust gases (300–450°F) rise naturally due to temperature difference.

-

The flue draws combustion gases up and out through gravity and heat.

-

Minimal mechanical assistance is needed — no fan required.

🧱 Pros of Metal Flues

-

Proven, simple technology.

-

Durable and long-lasting when properly maintained.

-

Suitable for older, 80% AFUE furnaces.

⚠️ Cons of Metal Flues

-

Hot exhaust wastes energy — up to 20% of fuel heat escapes.

-

Prone to corrosion over time.

-

Requires chimney or vertical venting — limits installation flexibility.

-

Inefficient for high-efficiency furnaces.

Mark’s old 80% model used this system:

“I had a galvanized metal pipe running through my attic. The installer said it was basically venting money out the roof.”

According to ASHRAE’s Venting Standards, metal flues are only suitable for non-condensing furnaces where exhaust gases stay hot enough to prevent water vapor from condensing inside the vent.

🧪 4. PVC Vent Systems: The Modern Solution for High-Efficiency Furnaces

When efficiency improves, exhaust gas temperature drops — and that changes everything. Furnaces like the Goodman GRVT961005DN extract so much heat from combustion that the remaining exhaust is cool enough (100–130°F) to vent safely through PVC pipes instead of metal.

🧱 How PVC Venting Works

-

The furnace uses a sealed combustion system, drawing in air through one PVC pipe and exhausting through another.

-

A draft inducer fan pushes cool exhaust outdoors.

-

Because the exhaust cools below the dew point, water vapor condenses into liquid, creating what’s known as a condensing furnace.

✅ Advantages of PVC Venting

-

Resistant to corrosion from acidic condensate.

-

Flexible routing: sidewall venting, no chimney required.

-

Sealed design prevents indoor air contamination.

-

Supports ultra-high efficiency (90–98% AFUE).

-

Safer and quieter operation.

⚠️ Potential Challenges

-

Condensate management is required.

-

Venting must be properly sloped to prevent water pooling.

-

Must use manufacturer-approved PVC/CPVC or polypropylene materials.

As EnergyStar.gov notes, PVC venting is an essential feature of modern ENERGY STAR-certified furnaces because it allows the use of cooler, slower, and more efficient exhaust systems.

⚙️ 5. Inside the Goodman GRVT961005DN: How Venting Works

The Goodman GRVT961005DN is a Category IV condensing furnace, which means it operates with sealed, fan-assisted venting.

🔧 Key Design Elements:

-

Dual-Pipe PVC System

-

One pipe pulls in outdoor air for combustion.

-

One pipe exhausts combustion gases.

-

Keeps indoor air sealed off for safety and efficiency.

-

-

Secondary Heat Exchanger

-

Extracts additional heat from exhaust gases.

-

Causes water vapor to condense, recapturing latent heat.

-

-

Condensate Management System

-

Collects and drains condensed water safely.

-

Includes integrated trap to prevent gas leaks.

-

-

Power Vent Fan

-

Ensures consistent exhaust flow regardless of external temperature or wind.

-

This setup makes the Goodman furnace nearly airtight — perfect for cold climates where natural draft systems can lose efficiency due to pressure changes.

You can review full specifications on GoodmanMfg.com.

💧 6. Condensation and Drainage: What Happens to the Water

High-efficiency furnaces don’t just produce heat — they produce condensate. When exhaust gases cool, water vapor turns to liquid inside the venting system.

⚙️ Condensate Management Steps:

-

Condensate forms inside the secondary heat exchanger.

-

It drains through PVC tubing to a floor drain or condensate pump.

-

Some homes add a neutralizer kit to balance acidity before disposal.

Mark’s installer added a small pump:

“It looks like a mini aquarium pump. Every so often, it hums quietly to push the water into the drain. Simple but effective.”

Proper condensate management ensures your venting system stays clear and prevents corrosion. It’s one of the major reasons PVC replaced metal for high-efficiency systems.

Learn more from HVAC.com’s Condensing Furnace Guide.

🧰 7. Upgrading: Switching from Metal to PVC Venting

If you’re replacing an older 80% furnace with a 96% Goodman model, your venting system must be upgraded. Here’s what to expect.

🧱 Retrofitting Steps:

-

Remove or cap old metal flue connected to chimney.

-

Install PVC vent and intake pipes through an exterior wall.

-

Add a condensate drain or pump.

-

Check local codes for termination clearance (often 12" above grade).

-

Seal joints with approved PVC cement.

💵 Cost Considerations

-

PVC materials: $200–$400

-

Labor for vent routing: $300–$600

-

Total retrofit cost: $400–$1,000, depending on layout and difficulty.

🏠 8. Common Venting Mistakes to Avoid

Proper installation is critical to avoid performance and safety issues. Here are common mistakes technicians (or DIYers) must steer clear of:

-

❌ Incorrect Vent Slope: PVC vent pipes must slope downward (¼" per foot) toward the furnace to allow condensate drainage.

-

❌ Improper Pipe Type: Use only Schedule 40 PVC/CPVC or approved polypropylene — never thin-wall plastic or drainpipe.

-

❌ Loose Joints: Use proper cement and primer; leaks can cause odor or performance loss.

-

❌ Vent Termination Too Close to Openings: Keep at least 12" above ground and 4 feet from windows or intakes.

-

❌ No Condensate Trap: Always install per manufacturer design to avoid sewer gas intrusion.

Goodman manuals clearly outline venting do’s and don’ts for each model — following them ensures warranty coverage and local code compliance.

For national standards, see NFPA 54 – National Fuel Gas Code.

🔥 9. PVC vs. Metal Flue: Side-by-Side Comparison

| Feature | PVC (Condensing Furnace) | Metal (Non-Condensing Furnace) |

|---|---|---|

| AFUE Efficiency | 90–98% | 80–83% |

| Exhaust Temperature | 100–130°F | 300–450°F |

| Combustion System | Sealed & fan-assisted | Open & natural draft |

| Material | PVC / CPVC / PP | Galvanized / Stainless Steel |

| Condensate | Yes (drain required) | No |

| Installation Type | Sidewall or roof vent | Chimney vent |

| Energy Waste | Minimal | Moderate to high |

| Safety | Sealed combustion | Risk of backdrafting |

| Maintenance | Drain and pipe checks | Chimney inspection |

Mark’s verdict after his Goodman upgrade:

“The new PVC system runs quieter, vents through the side of the house, and I don’t worry about backdrafting anymore. It’s cleaner, safer, and just works.”

🔍 10. Code and Safety Requirements for Furnace Venting

When it comes to gas furnace venting, following code isn’t optional — it’s essential.

Key National Standards

-

NFPA 54 (National Fuel Gas Code) – governs venting distances, pipe materials, and installation practices.

-

ANSI/ASTM D1785 – specifies Schedule 40 PVC/CPVC pipe standards.

-

IRC G2427 (International Residential Code) – regulates vent termination locations.

General Requirements

-

PVC vent terminations: minimum 12 inches above grade.

-

Maintain 4-foot clearance from windows, doors, and other air intakes.

-

Avoid venting under decks or soffits unless approved by the manufacturer.

-

All horizontal pipes must slope back to the furnace for proper drainage.

-

Only UL-listed pipe cement and fittings should be used.

Goodman furnaces are pre-certified for compliance with NFPA, CSA, and AHRI standards. Always verify your installer follows both manufacturer and local building codes.

🧹 11. Maintaining Your Venting System Year-Round

PVC and metal vent systems both need maintenance — but PVC systems are generally easier to care for.

🧰 Homeowner Maintenance Tips:

-

Inspect exterior vent openings monthly for snow, ice, or debris.

-

Clean condensate traps and drains annually to prevent clogs.

-

Check pipe joints and supports for cracks or loose fittings.

-

Have your furnace serviced every fall to verify vent pressure and fan operation.

During his annual tune-up, Mark’s technician performs a quick flue pressure check and flushes the condensate line — “simple preventive work that keeps things running perfectly.”

For more details, see Furnace Vent Maintenance Guide.

💬 12. Frequently Asked Questions

❓Why can’t I use my old metal vent for a new high-efficiency furnace?

Because the cooler exhaust gases from a 96% furnace cause condensation, which corrodes metal flues and leads to leaks.

❓Can I vent a high-efficiency furnace through the roof instead of a wall?

Yes — but sidewall venting is preferred for efficiency and easier drainage. Roof vents require longer runs and more slope management.

❓Do I need two PVC pipes for my Goodman furnace?

Yes. Goodman’s GRVT961005DN uses a two-pipe system — one for intake, one for exhaust — to ensure sealed combustion.

❓How long do PVC vent pipes last?

Typically 20–25 years when installed correctly. Inspect them annually for UV damage or brittleness.

⚡ 13. Real-World Example: Mark’s Furnace Upgrade

When Mark replaced his 25-year-old 80% metal-flue furnace with a Goodman 96% AFUE GRVT961005DN, the biggest change wasn’t the heat — it was the venting.

“Instead of running a big metal pipe through my attic, the installer drilled two 3-inch PVC pipes right through the basement wall. It’s cleaner, quieter, and it freed up attic space.”

He also noticed:

-

A 25% reduction in gas usage during the first winter.

-

No more chimney condensation stains.

-

Easier annual maintenance — just check the pipes and drain line.

That’s the difference modern venting makes.

🧩 14. Key Takeaways

✅ Metal flues are for 80% furnaces — hot exhaust, natural draft.

✅ PVC venting is for 96%+ high-efficiency furnaces — cool exhaust, sealed system.

✅ Goodman’s GRVT961005DN uses dual PVC venting for maximum safety and performance.

✅ Always follow slope, material, and clearance requirements during installation.

✅ Regular inspections keep your vent system safe and efficient.

In short, the flue may not be flashy, but it’s the backbone of your furnace’s performance.

📣 15. Final Thoughts: Safety, Efficiency, and Long-Term Value

Goodman’s approach to furnace design is simple: combine trusted engineering with modern venting technology for safe, efficient operation in every home.

Whether you’re upgrading from an older 80% system or building new, understanding PVC vs. metal venting helps you make smarter decisions for your comfort and safety.

So before your next installation, do what Mark did:

“Ask your installer to explain your venting setup. Once you see how it works, you’ll appreciate why Goodman designed it this way.”

In the next topic we will know more about: Energy Rebates and Tax Credits for 96% AFUE Furnaces in 2025