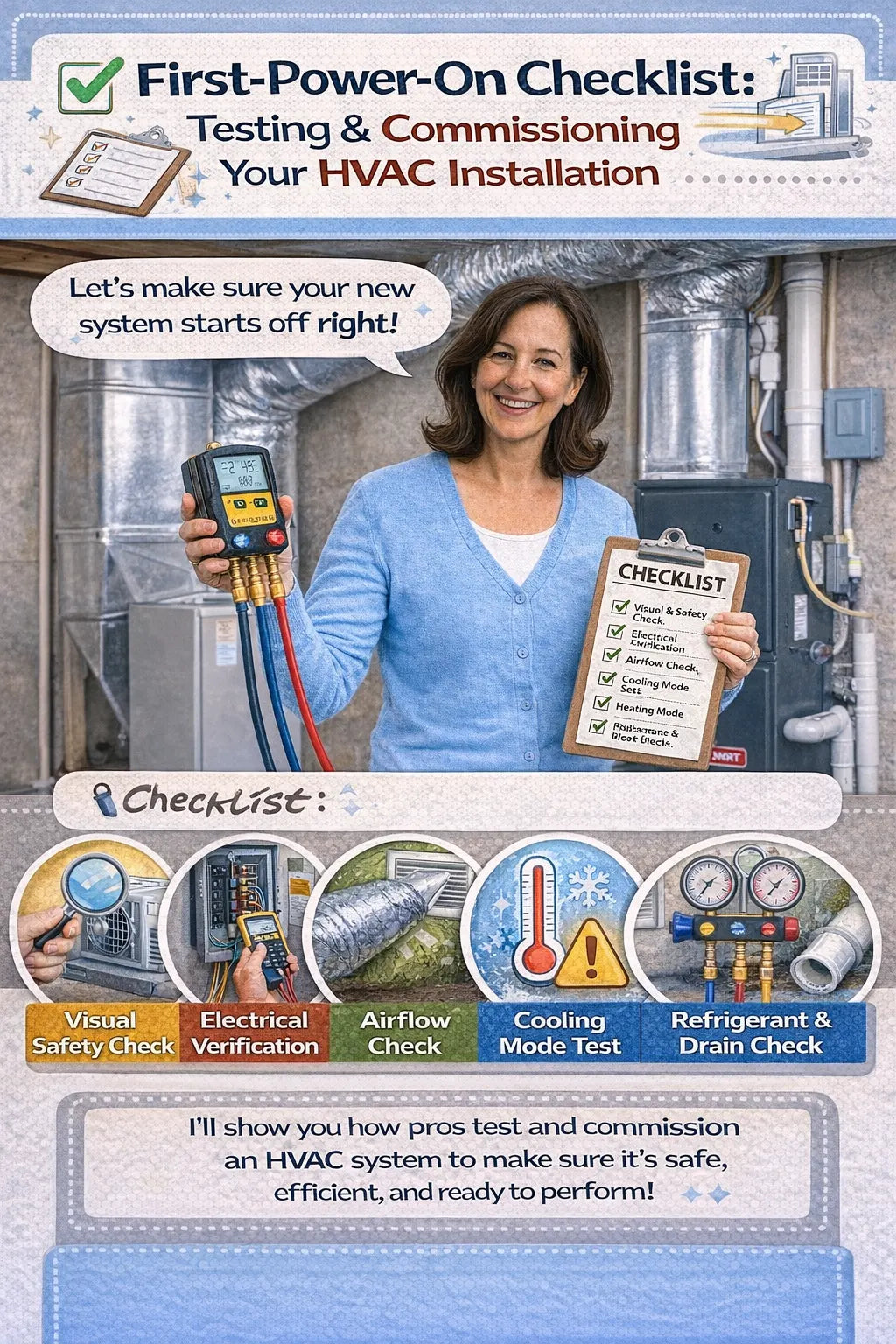

Turning on a brand-new HVAC system for the first time should feel exciting. Unfortunately, it’s also the moment when small installation mistakes reveal themselves—sometimes quietly, sometimes with a breaker trip, strange noise, or disappointing airflow.

That’s why professionals don’t just “flip the switch.”

They commission the system.

Commissioning is the process of testing, verifying, and documenting that your HVAC system is operating safely, efficiently, and exactly as designed. This guide walks you through a first-power-on checklist so you know what should happen, what to watch for, and what questions to ask—whether you’re DIY-installing parts of the system or supervising a professional install.

🧠 Why Commissioning Matters More Than Installation Alone

Installation answers one question:

👉 Is everything connected?

Commissioning answers the important ones:

-

Is airflow correct?

-

Is electrical load safe?

-

Is refrigerant charge accurate?

-

Are safety controls functioning?

-

Will this system last 15–20 years—or struggle in year one?

Skipping commissioning is like buying a new car and never checking oil pressure, tire pressure, or brakes.

🧾 Step 1: Pre-Power-On Visual & Safety Check

Before electricity flows, eyes and hands come first.

🔍 What should be verified visually

-

All panels securely installed

-

No loose wires or exposed terminals

-

Refrigerant line insulation intact

-

Condensate drain connected and sloped

-

Filters installed correctly (right size & direction)

🔒 Safety basics

-

Electrical disconnect accessible

-

Gas shutoff valve reachable (for furnaces)

-

No tools or debris left inside cabinets

If anything looks rushed or unfinished, pause before powering on.

⚡ Step 2: Electrical Verification Before Startup

Electrical issues are easiest to fix before load is applied.

What technicians should check

-

Correct breaker size (matches data plate MOCP)

-

Proper wire gauge

-

Tight, torqued connections

-

Correct polarity

-

Grounding and bonding intact

Undersized wiring or loose lugs may not fail immediately—but they will fail eventually.

🔗 External reference (NEC HVAC basics):

https://www.nfpa.org

🔌 Step 3: Initial Power-Up Sequence (What Should Happen)

When power is restored, the system should follow a predictable startup order.

Typical sequence

-

Control board powers up

-

System enters standby

-

Thermostat call initiates

-

Safety checks complete

-

Blower, inducer, or compressor engages (depending on mode)

Red flags

-

Immediate breaker trip

-

Repeated clicking or buzzing

-

Error codes on control board

-

Blower running without a call

If the system doesn’t behave calmly and predictably, stop and diagnose—don’t keep resetting.

🌬️ Step 4: Airflow & Blower Verification

Airflow is the foundation of comfort and efficiency.

What should be verified

-

Correct blower speed selected

-

Smooth, even airflow from registers

-

No excessive whistling or rattling

-

Return air unobstructed

A common mistake is leaving the blower on the factory default speed, which may not match your ductwork or system size.

🔗 External reference (airflow basics):

https://www.energy.gov/energysaver/maintaining-your-air-conditioner

🧊 Step 5: Cooling Mode Testing (Air Conditioners & Heat Pumps)

Once airflow is confirmed, cooling performance is tested.

Key checks

-

Outdoor condenser starts smoothly

-

Suction line becomes cool (not frozen)

-

Supply air temperature drops steadily

-

Condensate begins draining properly

Temperature split (general guidance)

-

16–22°F difference between return and supply air (context matters)

This is a diagnostic indicator, not a guarantee of correct charge—but it should be reasonable.

🔗 External reference (cooling performance fundamentals):

https://www.energy.gov/energysaver/air-conditioning

🔥 Step 6: Heating Mode Testing (Furnaces & Heat Pumps)

Heating tests focus on safety and stability.

Furnace checks

-

Inducer motor starts

-

Pressure switch closes

-

Ignition sequence completes

-

Flame is steady and even

-

Blower starts after delay

Heat pump checks

-

Reversing valve operation

-

No unusual noise during mode change

-

Proper airflow temperature rise

Temperature rise (furnaces)

Must fall within the manufacturer’s specified range—too high or too low indicates airflow issues.

🔗 External reference (furnace safety overview):

https://www.energy.gov/energysaver/furnaces-and-boilers

🧪 Step 7: Refrigerant System Verification

This is where commissioning becomes measured, not guessed.

Proper refrigerant checks include

-

System stabilized under load

-

Pressures within expected range

-

Subcooling or superheat verified per manufacturer

-

Line set length accounted for

-

No abnormal compressor sound

“Feels cold” is not commissioning. Numbers matter.

🔗 External reference (EPA refrigerant service practices):

https://www.epa.gov/section608/stationary-refrigeration-service-practice-requirements

💧 Step 8: Condensate Drain & Moisture Management

Water damage often shows up days—not minutes—after startup.

What to confirm

-

Condensate flowing freely

-

No leaks at joints or traps

-

Secondary drain protection functional

-

Condensate pump cycles correctly (if installed)

Pouring a small amount of water into the drain pan is a simple, effective test.

🧯 Step 9: Safety Control & Shutdown Testing

Safety devices must work before you trust the system.

Examples

-

Float switch shuts system off when triggered

-

Furnace limit switches respond correctly

-

Pressure switches open on vent obstruction

-

Breaker disconnects power when opened

No safety device should ever be bypassed—even temporarily.

🧠 Step 10: Thermostat Configuration & System Matching

Modern thermostats are powerful—but only when set correctly.

Verify:

-

Equipment type matches system (single vs multi-stage)

-

Heat source correctly identified

-

Fan settings appropriate

-

Wi-Fi and scheduling configured

Misconfigured thermostats cause many “new system” complaints.

🔗 External reference (thermostat setup basics)

🧾 Step 11: Documentation & Handover (Don’t Skip This)

A professional commissioning ends with paperwork.

What you should receive

-

Model & serial numbers

-

Startup readings (pressures, temps, static if measured)

-

Filter size and replacement schedule

-

Warranty registration confirmation

-

Installer contact info

This documentation protects you long after the installer leaves.

🚩 Common First-Power-On Red Flags

Stop and ask questions if you notice:

-

“We don’t need to check that”

-

No gauges or meters used

-

Thermostat left unconfigured

-

Safety switches disabled

-

No documentation offered

Commissioning isn’t optional—it’s responsible.

🧡 Samantha’s Final Advice

A system that starts isn’t the same as a system that’s ready.

Proper first-power-on commissioning:

-

prevents early failures

-

protects warranties

-

ensures comfort from day one

-

sets expectations for long-term performance

Buy this on Amazon at: https://amzn.to/43doyfq

In the next topic we will know more about: The Complete Step-by-Step Installation Guide for Your Goodman 3.5-Ton HVAC Unit