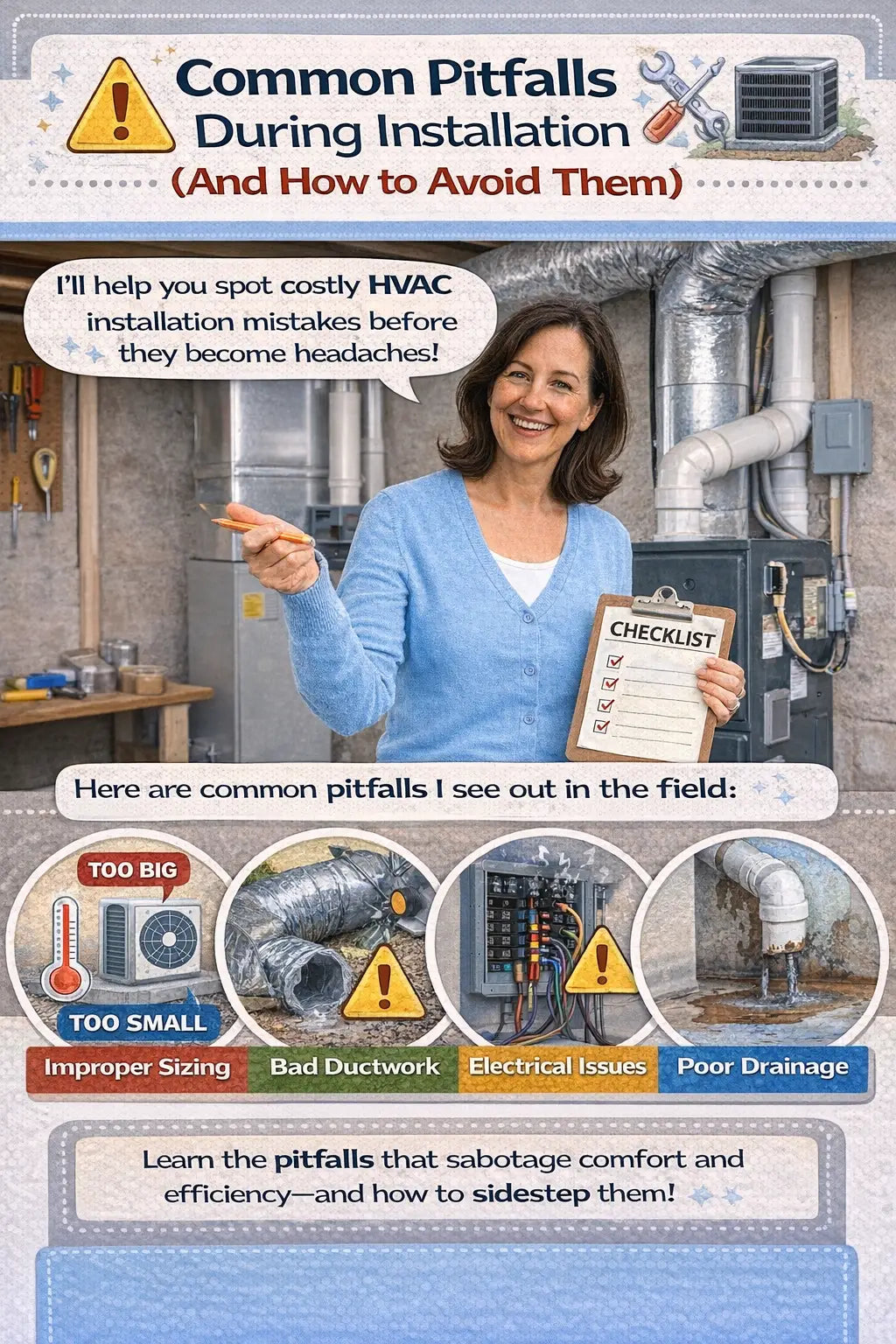

Most HVAC problems don’t start years later.

They start on installation day, quietly, when something is skipped, rushed, or assumed.

I’ve reviewed hundreds of installs where the equipment itself was perfectly fine—but comfort complaints, high bills, noise, or early failures showed up anyway. Almost every time, the root cause traced back to one or more common installation pitfalls.

This guide walks through the most frequent HVAC installation mistakes, explains why they matter, and—most importantly—shows you how to avoid them before they turn into expensive callbacks or long-term frustrations.

🧠 Why Installation Pitfalls Are So Common

Even good installers work under pressure:

-

tight schedules

-

labor shortages

-

reuse-what’s-there expectations

-

homeowners eager to “just get it running”

But HVAC systems aren’t forgiving. Small shortcuts compound into:

-

reduced efficiency

-

uneven comfort

-

shortened equipment life

-

failed inspections

-

voided warranties

Knowing what to watch for makes you an informed partner—not a difficult customer.

📐 Pitfall #1: Incorrect System Sizing (Too Big or Too Small)

This is the mistake that causes the most regret.

What goes wrong

-

Oversized systems short-cycle, struggle with humidity, and wear out faster

-

Undersized systems run constantly and never fully satisfy

Why it happens

-

“Rule of thumb” sizing

-

Replacing old equipment with the same tonnage without reevaluating the home

-

Skipping load calculations

How to avoid it

-

Insist on a Manual J load calculation

-

Account for insulation upgrades, windows, layout changes

-

Match equipment capacity to current home conditions—not past guesses

🔗 External reference (Manual J overview):

https://www.acca.org/standards/technical-manuals/manual-j

🌬️ Pitfall #2: Ignoring Ductwork Limitations

A new system cannot outperform bad ducts.

Common duct-related mistakes

-

Reusing undersized supply or return trunks

-

Crushed or sagging flex duct

-

Poor transitions right at the unit

-

Leaky connections sealed with tape only

Consequences

-

Loud airflow

-

Hot/cold rooms

-

Blower strain

-

Missed efficiency targets

How to avoid it

-

Evaluate duct sizing before installation day

-

Resize plenums when upsizing equipment

-

Seal with mastic, not just tape

-

Balance supply and return airflow

🔗 External reference (duct design & sealing basics)

🔌 Pitfall #3: Electrical Shortcuts and Undersized Circuits

Electrical issues don’t always fail immediately—they fail later.

What this looks like

-

Breakers tripping during heat waves

-

Burnt contactors

-

Control board failures

-

Failed inspections

Why it happens

-

Reusing old circuits not rated for new equipment

-

Incorrect breaker sizing

-

Poor grounding or bonding

How to avoid it

-

Verify MCA and MOCP on the equipment data plate

-

Upgrade circuits when required

-

Ensure proper disconnect placement and labeling

🔗 External reference (NEC basics for HVAC):

https://www.nfpa.org

🧊 Pitfall #4: Poor Refrigerant Line Practices

Refrigerant work is precision work—not guesswork.

Common refrigerant mistakes

-

Skipping nitrogen pressure testing

-

Inadequate evacuation (no micron gauge)

-

Incorrect line sizing or excessive length

-

“Topping off” instead of charging properly

What it leads to

-

Reduced capacity

-

Coil freezing

-

Compressor damage

-

Early system failure

How to avoid it

-

Pressure test with nitrogen

-

Evacuate to proper micron levels and verify decay

-

Charge by manufacturer-approved methods (weigh-in, subcooling, or superheat)

🔗 External reference (EPA refrigerant service practices):

https://www.epa.gov/section608/stationary-refrigeration-service-practice-requirements

💧 Pitfall #5: Improper Condensate Drainage

Water problems don’t announce themselves politely.

Typical mistakes

-

Flat or uphill drain lines

-

No secondary drain protection

-

Missing or incorrect traps

-

Drains routed where freezing occurs

What happens next

-

Ceiling stains

-

Mold growth

-

System shutdowns

-

Insurance claims

How to avoid it

-

Ensure proper slope on all drain lines

-

Use float switches where appropriate

-

Verify drainage before leaving the job

🔗 External reference (condensate & moisture control):

https://www.energy.gov/energysaver/moisture-control

🔥 Pitfall #6: Furnace Venting & Combustion Errors

These mistakes are safety-critical.

Red flags

-

Incorrect vent slope

-

Improper termination clearances

-

Intake and exhaust too close together

-

Pressure switches bypassed to “get it running”

Why it’s dangerous

-

Carbon monoxide risk

-

Flame rollout

-

Nuisance shutdowns

-

Failed inspections

How to avoid it

-

Follow manufacturer venting tables exactly

-

Maintain required clearances

-

Never bypass safety controls

🔗 External reference (furnace safety overview):

https://www.energy.gov/energysaver/furnaces-and-boilers

🧱 Pitfall #7: Poor Outdoor Condenser Placement

Where the condenser sits affects everything.

Common placement mistakes

-

Pad set directly on soil

-

Unit not level

-

Inadequate clearance for airflow

-

Placement where snow, debris, or water accumulate

Long-term impact

-

Noise complaints

-

Coil damage

-

Reduced efficiency

-

Premature compressor wear

How to avoid it

-

Use a stable, level pad or approved mount

-

Ensure proper drainage and clearance

-

Account for climate and yard conditions

🔗 External reference (manufacturer clearance guidance example):

https://iwae.com/media/manuals/goodman/glxs4b-installation.pdf

🧪 Pitfall #8: Skipping Commissioning & Verification

If it isn’t measured, it isn’t confirmed.

What often gets skipped

-

Static pressure testing

-

Airflow verification

-

Temperature rise checks

-

Final system documentation

Why this matters

Commissioning is where installers confirm the system operates as designed, not just that it turns on.

How to avoid it

-

Ask what commissioning steps are included

-

Request recorded readings

-

Ensure thermostat setup matches system staging

🔗 External reference (HVAC commissioning basics):

https://www.energy.gov/energysaver/maintaining-your-air-conditioner

🧾 Pitfall #9: Poor Documentation & Homeowner Handover

An install isn’t finished until the homeowner understands it.

Missing documentation leads to

-

Confusion during maintenance

-

Warranty issues

-

Difficulty troubleshooting later

How to avoid it

-

Keep model/serial numbers

-

Save startup readings

-

Understand filter sizes and schedules

-

Know who to call and when

Good installers educate. Great installers empower.

🚩 Universal Red Flags to Watch For

Pause the job if you hear:

-

“We always do it this way”

-

“That’s close enough”

-

“Inspections never check that”

-

“It’s normal for new systems to be loud”

Quality HVAC work is measured, verified, and explained.

🧡 Samantha’s Final Advice

Most installation mistakes aren’t malicious—they’re rushed or assumed.

But the difference between:

-

“It runs”

and -

“It runs beautifully for 15+ years”

is attention to these details.

Buy this on Amazon at: https://amzn.to/43doyfq

In the next topic we will know more about: First-Power-On Checklist: Testing & Commissioning Your HVAC Installation