🔌 What “3.5 kW Electric Heat” Really Means

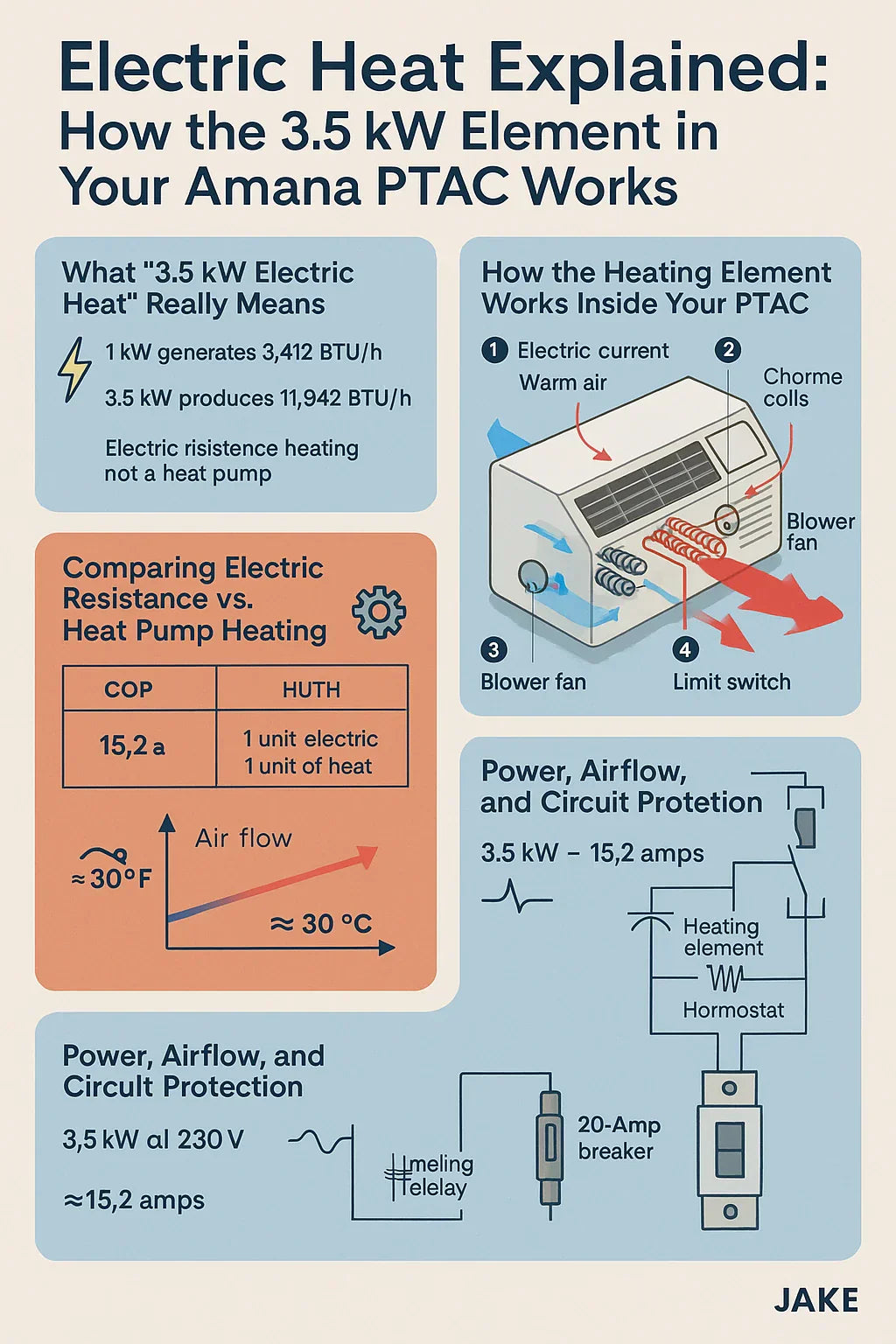

If you’ve ever looked at a PTAC spec sheet and seen “3.5 kW electric heat”, you might’ve wondered what that actually translates to in real-world comfort. In HVAC talk, “3.5 kilowatts” simply means the unit’s heater can draw up to 3,500 watts of electrical power.

Amana Distinctions Model 12,000 BTU PTAC Unit with 3.5 kW Electric Heat

Every watt you feed into an electric resistance heater becomes heat — no combustion, no compressor work. It’s 100 percent conversion efficiency.

To understand how much warmth that produces, convert kilowatts to BTUs (British Thermal Units):

1 kW = 3,412 BTU per hour

3.5 kW × 3,412 = ≈ 11,942 BTU/hr

So your Amana Distinctions PTAC’s electric heater adds nearly 12,000 BTUs of heating power, which lines up nicely with the unit’s 12,000 BTU cooling capacity. It’s like having one ton of cooling and one ton of electric heating built into the same wall chassis.

Why it matters:

-

🔥 Instant heat: Power flows, coils glow, warm air blows within seconds.

-

🧠 Simple design: No refrigerant change-over valves or compressors needed.

-

💪 Reliable backup: Works even in frigid weather when a heat-pump model may struggle.

📘 For a deeper dive into how electric resistance heating works, check out the U.S. Department of Energy’s overview.

🔥 How the Heating Element Works Inside Your PTAC

Inside the Amana PTAC chassis lives a small but mighty assembly of nichrome heating coils, similar to what’s in a toaster — just engineered for heavy-duty, controlled airflow.

Here’s the step-by-step:

-

Thermostat call for heat.

You set the PTAC to heat mode. When the sensed room temp drops below your setpoint, the control board energizes the heater relay. -

Electric current energizes the coils.

Electricity flows through the nichrome wire heating element. The high electrical resistance causes the wire to glow red-hot, typically between 1,400–1,800 °F. -

Blower draws room air across coils.

The fan inside the PTAC pulls cool room air across the element, picking up heat as it passes. -

Warm air circulates back into the room.

The heated air exits through the supply grille, quickly raising ambient temperature. -

Safety controls monitor operation.

Thermal limit switches and temperature sensors prevent overheating. If the air path gets blocked or the coil overheats, the circuit opens and shuts the heater down until it cools.

You can picture it like a miniature space heater built into your wall — but with professional-grade sensors, relays, and safety interlocks.

For wiring diagrams and component callouts, see the Amana PTAC Service Manual.

⚙️ Electric Resistance vs. Heat Pump Heating

Some PTACs use reverse-cycle heat pumps instead of, or in addition to, electric coils. The Amana Distinctions model we’re talking about relies solely on electric resistance heating.

🧊 Efficiency comparison

| System Type | Typical Coefficient of Performance (COP) | Notes |

|---|---|---|

| Electric resistance | 1.0 | 1 unit of electricity = 1 unit of heat |

| Heat pump | 2.0–3.0 | 1 unit of electricity = 2–3 units of heat moved |

In mild climates, a heat pump is usually cheaper to run. But in cold northern weather, its efficiency drops sharply — sometimes below that of simple resistance heat.

⚡ When electric heat shines

-

Works no matter how cold it gets.

-

Instant output — no frost or defrost cycles.

-

Lower maintenance: no compressor or reversing valve.

-

Great as a backup or supplemental heater in hotels and apartments.

As I like to say on job sites: “Electric heat never complains about the weather.”

Read the DOE’s Electric Resistance Heating Basics for more background.

💡 Power Draw, Amperage & Breaker Sizing

To make 3.5 kW of heat, your PTAC must pull some serious current. Here’s the math:

Because it’s a continuous load (can run for hours), code requires sizing at 125 % of that:

15.2 A × 1.25 = ≈ 19 A.

That’s why Amana specifies a dedicated 20-amp breaker and appropriately gauged wiring.

⚠️ Never plug a PTAC into a shared or undersized circuit — it can cause nuisance trips or overheated wires.

If you’re curious about the legal standards behind that rule, see the NFPA National Electrical Code.

🌡 Real-World Performance: What to Expect

When you switch to heat mode:

-

Warm air usually begins within 20–30 seconds.

-

Full temperature recovery for an average 400–500 sq ft room takes about 10–15 minutes.

-

Because there’s no compressor noise, heating mode often feels quieter than cooling.

Jake’s Tip 💬 – Keep the fan set to AUTO.

That allows the blower to cycle off once setpoint is reached, preventing continuous drafts and saving energy.

In the field, I often see 3.5 kW heaters hold a 70 °F room comfortably even when outdoor temps dip to 20–25 °F — assuming average insulation.

Here’s a quick reference:

| Room Size | Outdoor Temp | Expected Result |

|---|---|---|

| 400 sq ft | 35 °F | Maintains 72 °F easily |

| 500 sq ft | 25 °F | Maintains 70 °F with longer run time |

| 550 sq ft | 15 °F | May struggle to reach setpoint — needs supplemental heat |

That performance consistency is why hotels love 3.5 kW PTACs: guests expect instant heat regardless of weather.

🧰 Maintenance & Safety Tips for Electric Heat Elements

Even the simplest electric heater benefits from regular care. A dirty coil or clogged filter makes the element run hotter, shortening its life.

Jake’s Quarterly Checklist

-

Clean the air filter – Monthly in dusty areas.

-

Vacuum the coil area – Keep lint, pet hair, and dust off the element.

-

Check wiring terminals – Tighten any loose spade connectors.

-

Inspect the plug or hardwire – Discoloration or melted plastic = overheating.

-

Test the thermostat – Ensure the call for heat energizes only the intended circuit.

-

Listen for popping or humming – Could indicate a failing relay or loose connection.

Never spray cleaners directly onto the heating coil; use a dry brush or low-pressure vacuum.

For seasonal tune-ups, see the official Amana PTAC Maintenance Guide.

💰 Energy Efficiency and Operating Cost

Electric resistance heating is simple but can be energy-hungry. Let’s run the numbers:

Cost = Power (kW) × Hours × Rate ($/kWh)

Example:

3.5 kW × 3 hours/day × $0.14 = $1.47 per day

That’s about $44 per month if used daily for three hours.

Want to trim that?

-

Install a programmable or occupancy thermostat to shut off heat when the room is empty.

-

Use door and window seals to prevent drafts.

-

Keep filters clean for maximum airflow efficiency.

Check Energy Star’s PTAC Efficiency Tips for best-practice advice.

🧩 When to Use Electric Heat vs. Other Modes

Some Amana PTACs combine electric and heat-pump operation. The Distinctions 12 k BTU model is electric-only, but if yours has both, the controller decides automatically:

-

Above ≈ 40 °F: heat pump mode for efficiency.

-

Below ≈ 35 °F: electric resistance takes over.

In all-electric models, you just set your temperature and let the element handle it.

Jake’s Rule of Thumb 🧮 – Use electric heat for quick recovery or extreme cold; rely on the heat pump (if equipped) for mild conditions.

For a side-by-side breakdown, read The Furnace Outlet’s Electric vs. Heat Pump PTACs.

🧯 Safety Systems Built In

Amana designs multiple safety redundancies into each PTAC:

-

High-limit thermostat: Trips if coil surface exceeds safe temperature.

-

Thermal fuse: Single-use backup if limit fails.

-

Airflow switch: Ensures fan is running before element energizes.

-

Solid-state control board: Prevents simultaneous cooling/heating circuits.

If your unit ever shuts off and won’t restart until cooled, it’s likely these safeties doing their job. That’s a sign to clean filters or check for airflow obstruction — not to bypass the limit!

🧠 How the Thermostat and Relay Talk

Think of the PTAC as a small automation system:

-

The thermostat sensor measures room temp.

-

When heating is needed, the control board energizes a heater relay.

-

The relay closes, sending full line voltage to the coil.

-

Once the sensor detects setpoint reached, the board opens the relay.

It’s an elegant circuit that keeps power draw steady and avoids the massive inrush current spikes typical of baseboard heaters.

If you’re comfortable reading schematics, Amana’s manuals detail these logic sequences under “Electric Heat Control Operation.”

🧾 Understanding 3.5 kW in the Context of Room Load

Recall from the previous article that one ton of cooling ≈ 12,000 BTU. Since the 3.5 kW element outputs nearly 12,000 BTU/hr, your heater is essentially a one-ton electric furnace built into the wall.

For a 450–500 sq ft room with good insulation, that’s ample. If your space is larger or poorly sealed, you might need to run it longer or add secondary heat (baseboard, infrared panel, etc.).

🧮 Converting Electrical Input to Comfort

Let’s look at airflow and temperature rise.

A typical Amana PTAC moves ~370 CFM (cubic feet per minute).

Temperature rise ΔT = ( BTU / (CFM × 1.08) ).

Plug numbers: 11,942 / (370 × 1.08) ≈ 30 °F rise.

That means if the return air is 68 °F, supply air will be ~98 °F. That’s comfortably warm but not scalding — perfect for continuous use.

⚖️ Pros and Cons of Electric Resistance Heat

👍 Advantages

-

100 % efficient at point of use

-

Instant response

-

Low maintenance

-

No refrigerant handling

-

Reliable in any climate

👎 Disadvantages

-

Higher operating cost where electricity > $0.12/kWh

-

Requires dedicated circuits

-

Can’t leverage ambient heat like a heat pump

If your region has high electric rates, consider models that combine electric and heat-pump modes to balance cost and reliability.

🧩 Troubleshooting Common Electric Heat Issues

Even robust PTACs can develop hiccups. Here’s what I check first on service calls:

❄️ 1. Unit Blows Cold Air in Heat Mode

-

Heater relay stuck open

-

Blown thermal fuse

-

Open heating coil

Use a multimeter to verify coil continuity. If resistance reads infinite, replace the element.

⚠️ 2. Breaker Trips When Heating

-

Shorted wire or failing element

-

Over-amperage due to dirty filter (airflow restriction = overheat = higher current)

🌫 3. Smells Like Burning Dust

That’s common at first seasonal startup. Run the unit on fan-only for five minutes to clear residual dust.

💡 4. No Heat Light / Indicator

Could be a faulty control board or sensor mis-read. Check low-voltage signals to confirm call for heat.

The HVAC School PTAC Troubleshooting Guide covers these diagnostics in more depth.

🛠 Jake’s Pro Tips for Running Electric Heat Efficiently

-

Seal drafts first. Electric heat works best when your envelope is tight.

-

Use fan AUTO. Avoid running fan continuously — it pushes unheated air after the coil shuts off.

-

Night setback. Drop setpoint 3–4 °F while sleeping.

-

Routine cleaning. Dust is an insulator — keep coils clean.

-

Don’t block airflow. Leave at least 18 inches clear in front of the PTAC.

-

Inspect annually. A 10-minute inspection prevents costly repairs later.

🧾 Summary: Jake’s Takeaway on the 3.5 kW Amana PTAC

-

3.5 kW = ≈ 12,000 BTU/hr of steady, reliable heat.

-

Perfect for rooms ≈ 400–500 sq ft with average insulation.

-

Requires a dedicated 20-amp circuit.

-

Virtually maintenance-free aside from cleaning.

-

Instant comfort in cold weather without the complexity of heat pumps.

If you understand what 3.5 kW really means — how it draws power, how it delivers heat, and how to maintain it — you’ll squeeze every bit of performance and efficiency out of your Amana PTAC for years to come.

In the next topic we will know more about: Amana Distinctions vs. GE Zoneline vs. Hotpoint: Which PTAC Is the Better Buy?