🏡 Introduction: “Most duct problems hide in plain sight — until the system turns on.”

Samantha has walked into hundreds of homes where the furnace or AC was blamed for comfort issues:

-

“The system is too loud.”

-

“My new furnace doesn’t heat the upstairs.”

-

“The airflow feels weak ever since the upgrade.”

-

“My energy bill went UP after installing a high-efficiency unit.”

She hears the same line again and again:

“The equipment must be defective.”

But 8 times out of 10, the equipment is perfectly fine.

The real issue is the ductwork — especially ductwork that was installed quickly, cheaply, or without understanding airflow physics.

Samantha calls these post-installation duct regrets, because they are mistakes homeowners only recognize after the system is running and the comfort problems appear.

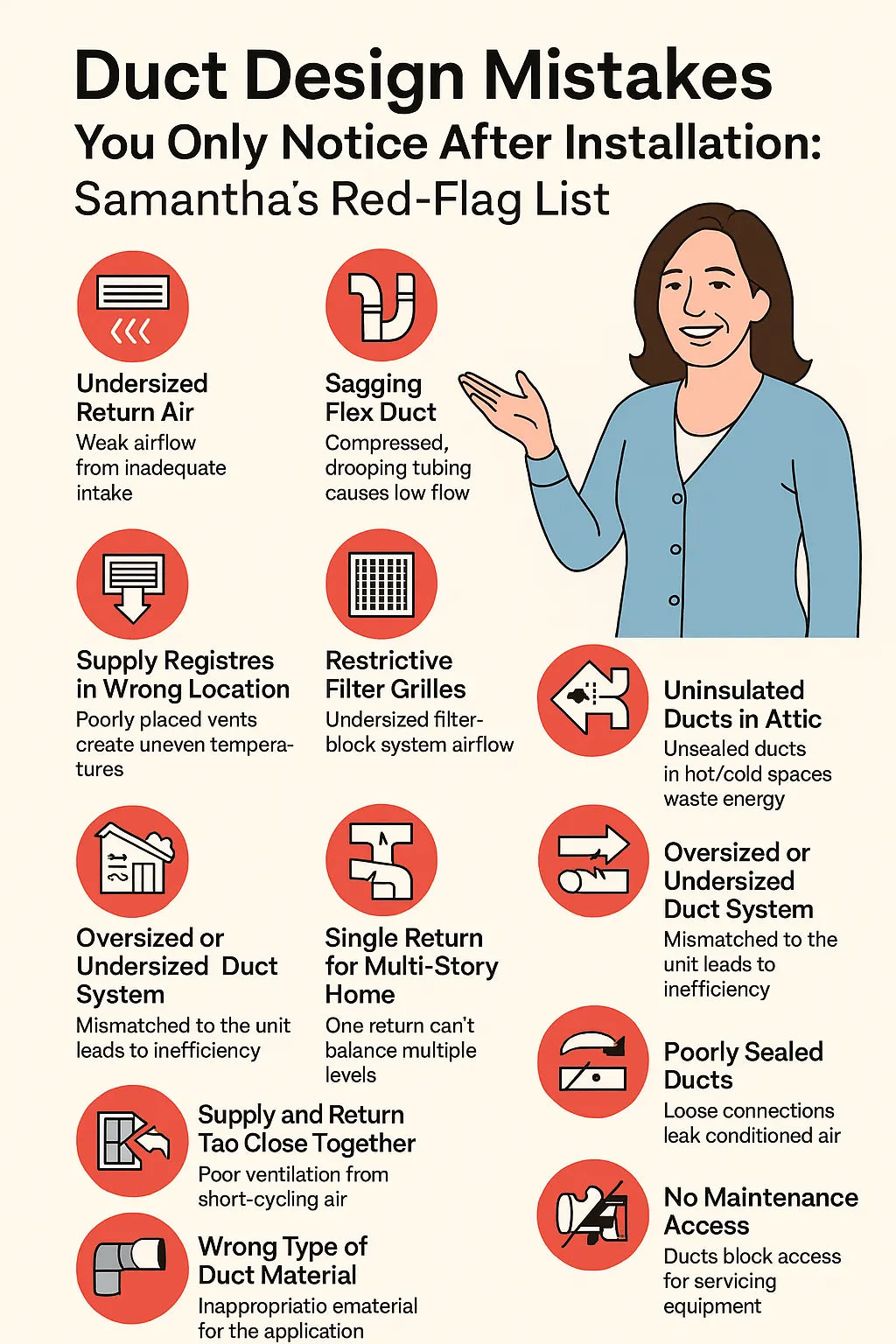

In this guide, Samantha walks you through the most common duct design red flags she finds — the ones that silently sabotage comfort, efficiency, and noise.

80,000 BTU 96% AFUE Upflow/Horizontal Two Stage Goodman Gas Furnace - GR9T960804CN

And most importantly: she shows how homeowners can identify these mistakes themselves.

🔴 1. Undersized Return Air — Samantha’s #1 Most Damaging Duct Mistake

(“Your system can only blow out what it can pull in.”)

Samantha always starts with returns because low return airflow destroys everything else:

-

static pressure spikes

-

blower noise increases

-

efficiency drops

-

rooms become uneven

-

coils freeze

-

furnaces overheat

ENERGY STAR has published data showing that improper duct sizing and return restrictions are among the top causes of poor HVAC performance:

🧠 Why This Happens

Because most installers size supply ducts carefully — but treat return ducts as “whatever fits.”

And that never works.

Samantha explains the homeowner version:

“If your system can’t breathe in, it can’t breathe out. Period.”

🛑 Samantha’s Red Flags

You may have an undersized return if:

-

your system sounds “windy” at the furnace closet

-

the blower is loud

-

return grille whistles

-

bedrooms pressurize when doors are closed

-

filters clog unusually fast

-

airflow drops when a clean filter is installed

🧰 Samantha’s Fixes

-

add additional return grilles

-

enlarge the return trunk

-

switch to a media filter cabinet

-

avoid return filter grilles with 1-inch filters

-

add jump ducts or transfer grilles to bedrooms

🔴 2. Long Runs of Sagging Flex Duct — The Silent Airflow Killer

(“Flex is great… until it becomes a hammock.”)

Flex duct is easy to install and inexpensive — which makes it the most abused material in residential HVAC.

Samantha sees the same mistakes:

-

sagging

-

kinks

-

sharp bends

-

compressed insulation

-

unsupported long runs

The Department of Energy warns that flex duct installed without proper support dramatically reduces airflow.

🧠 Why It Matters

Every bend adds resistance.

Every sag reduces airflow.

Every compression reduces internal diameter.

Samantha describes it simply:

“Flex duct needs to be pulled tight like a guitar string — not drooping like a jump rope.”

🛑 Samantha’s Red Flags

-

rooms with noticeably weaker airflow

-

loud airflow “rushing” noise

-

flex ducts lying directly on attic insulation

-

kinks near takeoffs

-

flex runs longer than 15–20 feet without rigid sections

🧰 Samantha’s Fixes

-

shorten runs using rigid trunk lines

-

support flex every 4 feet

-

replace crushed or kinked sections

-

keep bends at 45° or less when possible

-

stretch the flex tight (it increases effective diameter)

🔴 3. Too Many 90-Degree Elbows — The “Airflow Speed Bumps”

Right-angle fittings are fast and cheap.

They are also static pressure generators.

Samantha explains:

“Every 90-degree turn is like asking your system to sprint and then stop on a dime.”

ASHRAE guidelines show that elbows dramatically increase resistance inside ducts:

🔗 https://www.ashrae.org/

🛑 Samantha’s Red Flags

-

rattling noises

-

hot and cold spots

-

supply vents that hiss

-

registers that barely move air

🧰 Samantha’s Fixes

-

replace 90° elbows with long-sweeping elbows

-

use turning vanes for metal duct corners

-

reroute duct paths more naturally

-

increase trunk diameter to compensate

🔴 4. Supply Registers in the Wrong Location — The Comfort Wrecker

Register placement matters far more than most homeowners realize.

Samantha teaches:

“It’s not the vent. It’s where the vent POINTS.”

Incorrect register placement leads to:

-

uneven temperatures

-

poor circulation

-

drafts

-

stagnant air pockets

-

comfort “dead zones”

🛑 Samantha’s Red Flags

-

registers blowing upward into ceilings

-

vents behind furniture

-

vents facing walls or cabinets

-

registers placed too close to returns

-

registers firing air in the wrong direction for room shape

🧰 Samantha’s Fixes

-

move vents to exterior walls (ideal for heat load)

-

use high-throw registers to push air across long rooms

-

reposition returns away from supplies

-

upgrade to directional multi-blade registers

-

avoid blowing air directly into obstacles

🔴 5. Restrictive Filter Grilles — The “Loud but Low-Airflow” Design Mistake

Many installers place filters in return grilles, not in a filter cabinet.

This works with large grilles.

It fails with small ones.

Samantha calls this mistake “the 1-inch choke.”

A 1-inch filter behind a small grille becomes:

-

loud

-

restrictive

-

inefficient

-

high-static

Lennox and Carrier both publish pressure-drop data showing dramatic airflow loss when filters are too small:

🔗 https://www.lennox.com/residential

🔗 https://www.carrier.com/residential/en/us/

🛑 Samantha’s Red Flags

-

loud whistling at return grilles

-

blower noise increases with a new filter

-

home feels dusty despite frequent filter changes

-

weak airflow even with a clean filter

🧰 Samantha’s Fixes

-

replace the 1-inch grille with a full media cabinet

-

increase return grille size

-

relocate the filter to the furnace

-

use lower-pressure-drop filters (MERV 8–11 instead of MERV 13+)

🔴 6. Single Return for a Multi-Story Home — Samantha’s “Gravity Problem”

One return vent cannot serve:

-

a two-story home

-

a large ranch

-

a home with closed-off rooms

-

bedrooms with tight doors

Samantha explains it simply:

“Air wants to take the easiest path. With only one return, it never reaches the rooms that need it.”

🛑 Samantha’s Red Flags

-

second floor too hot in summer

-

first floor too cold in winter

-

bedrooms feel stuffy at night

-

temperatures swing 2–6 degrees between rooms

🧰 Samantha’s Fixes

-

add returns to upper floors

-

add transfer grilles or jump ducts

-

widen the main return drop

-

install return pathways into closed rooms

🔴 7. Ducts Installed in Unconditioned Spaces Without Proper Insulation

This is a hidden efficiency killer.

Ducts running through:

-

attics

-

crawlspaces

-

garages

…lose enormous amounts of energy.

DOE estimates 20–30% of heating/cooling is lost through uninsulated ducts in unconditioned spaces:

🛑 Samantha’s Red Flags

-

AC runs long on hot days

-

furnace cycles frequently in winter

-

attic ducts feel warm/cold to the touch

-

insulation around ducts is crushed or missing

🧰 Samantha’s Fixes

-

insulate ducts to R-8 or higher

-

seal joints with mastic, not tape

-

keep ducts low in the attic, under insulation where possible

-

cover exposed metal trunks

🔴 8. Oversized or Undersized Duct Systems — The “Math Mistake” That Hurts Everything

Samantha often finds that the furnace or AC was sized correctly —

but the ducts were not.

Ducts must be sized by:

-

CFM

-

friction rate

-

static pressure

-

blower capability

-

run length

-

fittings

Most installers “guesstimate.”

Samantha does duct math.

🛑 Samantha’s Red Flags

-

new system is louder than the old one

-

equipment short-cycles

-

airflow feels “weak and fast” instead of “smooth and full”

-

static pressure over 0.6–0.8 in. w.c. (too high)

-

temperature split is too large

🧰 Samantha’s Fixes

-

recalc supply CFMs per room load

-

resize trunk lines

-

reduce static pressure by enlarging returns

-

choose ECM blower settings matched to duct size

🔴 9. Poorly Sealed Ducts — The Invisible Comfort Leak

Samantha says leaking ducts are like “throwing conditioned air into the walls.”

Common leakage areas:

-

supply boots

-

trunk-to-branch connections

-

seams in metal trunk lines

-

around air handler cabinet

-

panned floor joists (illegal in many areas)

DOE states that duct leakage wastes up to 30% of heating and cooling energy

🛑 Samantha’s Red Flags

-

dust streaks around duct seams

-

spiderwebs moving near leaks

-

inconsistent temperatures between rooms

-

high utility bills

-

visible gaps or incomplete mastic seal

🧰 Samantha’s Fixes

-

seal seams with mastic

-

insulate after sealing

-

replace leaky flex boots

-

avoid tape-only joints

🔴 10. Supply and Return Too Close Together — The “Air Short-Circuit” Problem

Samantha has seen homes where the supply blows warm or cold air straight into the return grille.

That means:

-

wasted airflow

-

poor circulation

-

fast cycling

-

humidity issues

She explains:

“The air doesn’t have a chance to mix with the room. It goes straight back to the furnace like a boomerang.”

🛑 Samantha’s Red Flags

-

return grille is on the same wall as a supply

-

uncomfortable room despite high airflow

-

quick temperature swings

-

system cycles too frequently

🧰 Samantha’s Fixes

-

relocate either the supply or return

-

use high-throw registers to spread air farther

-

add additional supply registers

🔴 11. Using the Wrong Type of Duct Material for the Application

Samantha sees duct materials used incorrectly:

Metal where flex should be

(too loud, too rigid for tight spaces)

Flex where metal should be

(too much pressure loss)

Old ductboard still in use

(prone to mold if aging)

Uninsulated metal trunks in attics

(huge energy losses)

🛑 Samantha’s Red Flags

-

loud metal popping noises

-

moisture on ductboard

-

flex runs over 25 feet

-

exposed metal in unconditioned spaces

🧰 Samantha’s Fixes

-

use metal for trunks

-

use flex only for short, final connections

-

replace aging ductboard

-

wrap exposed ducts with proper insulation

🔴 12. No Thought Given to Maintenance Access — The “We Can’t Reach It” Problem

Samantha has seen furnaces and air handlers boxed in by:

-

tight closets

-

narrow attics

-

blocked return cavities

-

inaccessible filter cabinets

-

duct transitions covering service panels

This leads to:

-

expensive service calls

-

neglected maintenance

-

dirtier coils

-

clogged filters

-

higher static pressure over time

This mistake isn’t immediately obvious — but it always bites later.

🛑 Samantha’s Red Flags

-

filter impossible to reach

-

blower door blocked by ducts

-

technician complains about access

-

return duct blocking service panel

🧰 Samantha’s Fixes

-

reroute ductwork to allow a service corridor

-

move filter cabinet to an accessible location

-

rebuild cramped transitions

-

use compact duct fittings

⭐ Samantha’s “Installation Survivors Checklist”

(Every homeowner should use this after a new system is installed.)

Airflow & Pressure

-

Return ducts sized correctly

-

Flex pulled tight

-

No kinks or crushed runs

-

Static pressure under 0.6 in. w.c.

Noise

-

No hissing supply vents

-

No whistling returns

-

Registers blowing in correct direction

Comfort

-

No room more than 2°F different than others

-

Good airflow at each register

-

No dramatic pressure changes when doors close

Construction

-

Long-sweep elbows

-

Straight ducts where possible

-

Sealed connections (mastic)

-

Insulated ducts in unconditioned spaces

Maintenance

-

Filter easily accessible

-

Coil access not blocked

-

Furnace panels open freely

🌟 Conclusion: “Good Equipment Can’t Save Bad Ductwork — But Good Ductwork Can Save Any System.”

Samantha loves reminding homeowners:

“Your ducts are the highways your comfort travels on.”

If those highways are:

-

narrow

-

blocked

-

twisted

-

leaking

-

noisy

-

too long

-

poorly insulated

…then even the best furnace or AC in the world can’t deliver comfort.

But when ductwork is designed well, your home feels:

-

quieter

-

more even

-

more efficient

-

more stable

-

more comfortable

And your system lasts longer with fewer repairs.

Because duct design isn’t just a technical detail — it’s the heart of the entire HVAC experience.

Buy this on Amazon at: https://amzn.to/4hJt23t

In the next topic we will know more about: Duct Design Mistakes You Only Notice After Installation: Samantha’s Red-Flag List