🌬️ Introduction: “A High-Efficiency Furnace Only Stays Efficient If You Vent and Drain It Properly.”

Most homeowners assume installing a 96% AFUE furnace is simple:

replace the old unit, connect the gas line, and turn it on.

Samantha knows better.

High-efficiency furnaces are powerful, intelligent machines — but they are also condensing appliances, and that means:

-

water comes out of the exhaust

-

drains can freeze

-

vent slopes matter

-

pipe size matters

-

pipe length matters

-

termination placement matters

-

traps and pumps matter

-

safety switches matter

In other words:

A 96% furnace doesn’t just heat your home — it breathes, drains, slopes, and flows.

And the system only performs as well as the venting and condensate design behind it.

That’s why Samantha teaches homeowners her simple, practical set of rules—the same rules that prevent 90% of comfort and reliability problems she sees with high-efficiency furnaces.

80,000 BTU 96% AFUE Upflow/Horizontal Two Stage Goodman Gas Furnace - GR9T960804CN

Today, she walks you through everything a homeowner needs to know to ensure their furnace runs quietly, safely, efficiently, and stress-free for years.

🏠 1. Why 96% Furnaces Need Special Venting (Samantha’s “Combustion Chemistry” Explanation)

A 96% AFUE furnace extracts so much heat from the combustion gases that the exhaust cools enough to turn the vapor into liquid water.

This is why it’s called a condensing furnace.

Samantha explains it simply:

“Your furnace vents out warm moisture — not hot smoke.”

This changes everything.

Instead of hot metal flue pipes, high-efficiency furnaces use PVC or polypropylene pipes because the exhaust is cool enough to touch.

But the moment water enters the vent system, Samantha says two things must be perfectly designed:

1. The vent slope

To guide condensed water back to the furnace drain.

2. The vent termination

To prevent wind, snow, or pressure from blocking airflow.

And she emphasizes:

“If your venting is wrong, nothing else in the system can work right.”

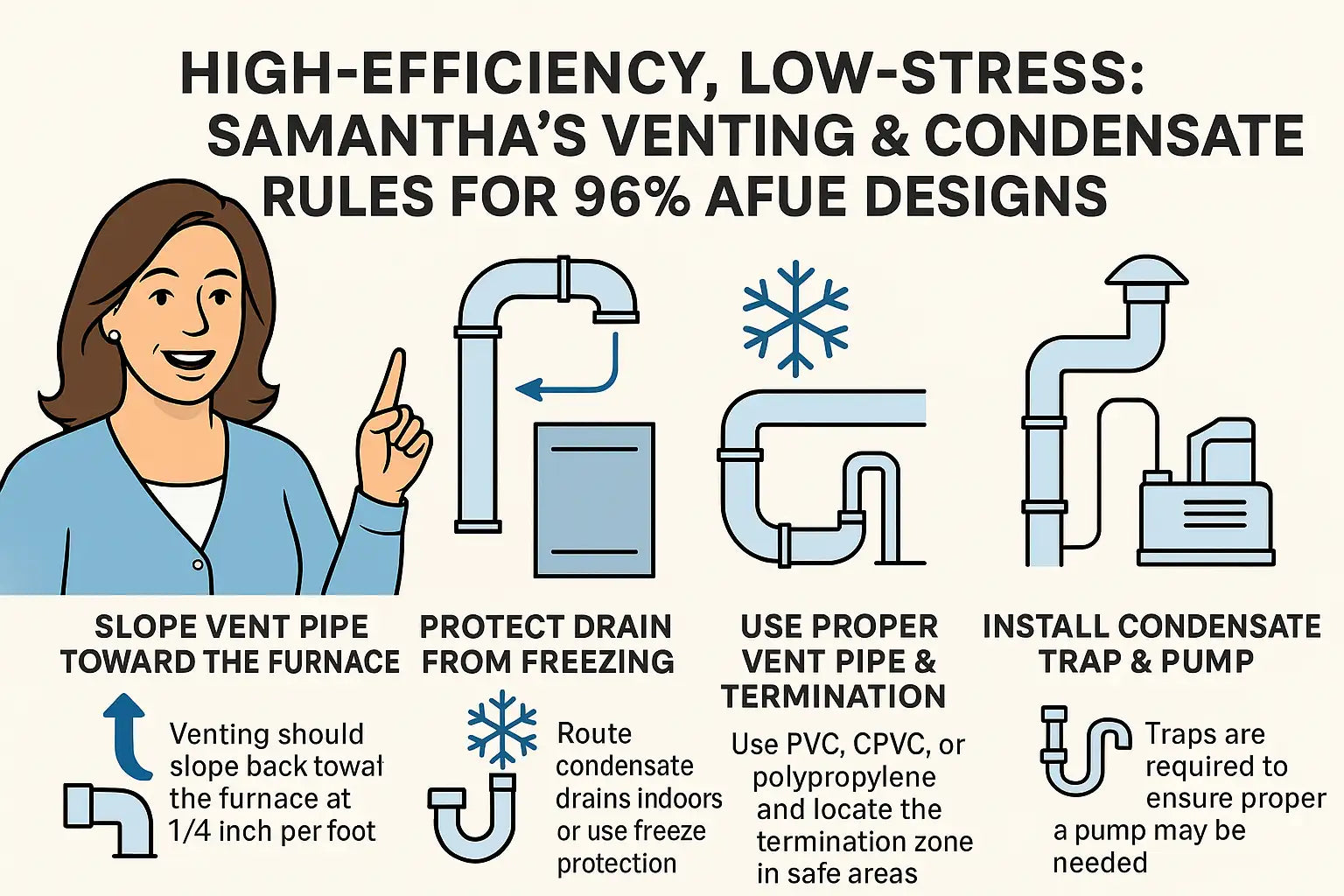

📏 2. Samantha’s First Rule: The Vent Must Always Slope Toward the Furnace

Every condensing furnace manufacturer — from Goodman to Carrier to Trane — requires a specific vent slope.

Most state:

¼ inch per foot toward the furnace.

(Also referenced in manufacturer instructions and code standards.)

Carrier’s installation guide makes this explicit:

🔗 https://www.carrier.com/residential/en/us/

Goodman’s instructions echo the same rule:

🔗 https://www.goodmanmfg.com/resources

Samantha explains the “why” in her calm, approachable tone:

“Think of the vent like a roof gutter. The water must run downhill — or it backs up.”

If the slope is wrong, condensation pools inside the vent.

This leads to:

-

gurgling noises

-

blocked exhaust

-

pressure switch trips

-

furnace shutdowns

-

corrosion at fittings

Homeowners often think their furnace is “broken,” but Samantha knows to check slope first.

🧊 3. Samantha’s Second Rule: Protect the Vent Against Freezing

In cold climates, any standing water in the vent can turn into a plug of ice.

Samantha has seen:

-

frozen vents

-

cracked PVC elbows

-

ice buildup at termination caps

-

furnaces shutting down repeatedly

DOE also warns that improper venting in cold climates increases failure risk:

🔗 https://www.energy.gov/energysaver/furnaces-and-boilers

To prevent ice problems, Samantha follows this checklist:

❄️ Cold-Weather Vent Protection Checklist

-

Use 2" or 3" pipe based on manufacturer recommendations

-

Slope piping toward furnace (never away)

-

Avoid pipe sagging (support every 3–4 feet)

-

Keep vent terminations above snow lines

-

Use concentric vent kits with drip protection

-

Seal wall penetrations against drafts

-

Avoid shaded areas with freezing airflow

She explains the most common problem:

“The vent freezes when the slope is wrong, not because the weather is cold.”

🧪 4. Samantha’s Third Rule: Use the Right Vent Pipe Material (PVC, CPVC, Polypropylene)

Samantha walks homeowners through this in simple language.

PVC (most common)

Rated for low-temperature exhaust from high-efficiency furnaces.

CPVC (for longer runs or warmer exhaust temps)

Stronger and more heat-tolerant.

Polypropylene (modern, smooth, and efficient)

Used in some premium furnaces for ultra-quiet airflow.

Manufacturers specify acceptable materials in their installation requirements — it’s critical to follow those charts.

⚠️ What Samantha Warns About

-

Never mix PVC and ABS

-

Never oversize vent pipes

-

Never use plumbing-grade PVC (only vent-grade)

-

Never install pipes without primer (local code may require purple primer)

She explains:

“Your furnace creates pressure. The vent must match that pressure — exactly.”

🔧 5. Samantha’s Fourth Rule: Intake and Exhaust Must Be Balanced

A 96% furnace uses two pipes:

-

intake (fresh outdoor air)

-

exhaust (vapor + gases)

These pipes must be:

-

sized correctly

-

the same length (ideally)

-

terminated in the same pressure zone

Samantha says:

“You wouldn’t breathe through a coffee straw and exhale through a garden hose.”

Your furnace is no different.

🌬️ Samantha’s Balanced Venting Checklist

Length

The intake and exhaust should be close in total length so the furnace doesn’t fight uneven pressure.

Number of elbows

Each elbow counts as length in vent calculations.

Termination zone

Both pipes should end:

-

on the same side of the house

-

away from windows

-

away from dryer vents

-

away from plumbing vents

-

away from prevailing winds

This aligns with manufacturer rules and IRC vent termination guidelines:

🔗 https://codes.iccsafe.org/

💧 6. Samantha’s Condensate Rule #1: The Drain Must Have a Proper Trap

Condensing furnaces produce gallons of water per day — all of which must drain safely.

This is why they include:

-

a primary drain

-

an internal or external trap

-

sometimes a condensate pump

Samantha says:

“If the trap isn’t there, air blows out instead of water draining out.”

Without a trap:

-

furnace loses suction

-

pressure switches fail

-

water backs up

-

system shuts down

This is a common oversight in improper installations — and one of the easiest to diagnose.

🛁 7. Samantha’s Condensate Rule #2: The Drain Must Be Protected From Freezing

In cold climates, drains can freeze solid.

To prevent this, Samantha teaches:

Cold-Climate Condensate Protection

-

Route the drain indoors as long as possible

-

Never drain outside without heat tape or insulation

-

Use heated drain lines if draining into a garage

-

Install overflow safety switches

-

Ensure the drain slopes continuously (no dips)

DOE’s guidance on drain protection stresses similar requirements:

🔗 https://www.energy.gov/energysaver/air-conditioning

Her simple explanation:

“Water doesn’t wait for spring. If the drain freezes, the furnace stops.”

🧼 8. Samantha’s Condensate Rule #3: Use the Right Pump (and Maintain It!)

Homes without gravity drainage need a condensate pump.

Samantha prefers pumps that include:

-

overflow safety switches

-

easy access covers

-

removable reservoirs

She tells homeowners:

“A dirty condensate pump can shut down a perfect furnace.”

Signs a pump needs service:

-

gurgling

-

repeated cycling

-

water pooling

-

furnace shutting off on safety

Samantha recommends cleaning pumps every 6–12 months.

🚿 9. Samantha’s Condensate Rule #4: Avoid Long Horizontal Drains

Condensate drains must be sloped.

Water sitting horizontally leads to:

-

mildew

-

bacterial slime

-

line blockage

-

pump overspill

Samantha requires:

¼ inch per foot slope minimum

(Same as plumbing best practices.)

She emphasizes:

“Where water sits, problems grow.”

🚨 10. Samantha’s Safety Rule: Never Combine Furnace and AC Condensate Lines Without a Plan

Combo drain lines are common — but dangerous when done incorrectly.

Samantha’s rule is clear:

“Two appliances can share a line only if each has its own trap.”

This prevents:

-

crossflow

-

suction issues

-

blower interference

-

coil flooding

-

furnace lockouts

A shared line without proper trapping is a recipe for disaster.

🔇 11. Samantha’s Noise Rule: Venting Affects System Sound

Homeowners rarely connect venting to noise — but Samantha explains it beautifully:

“Your furnace is quiet. Bad venting makes it loud.”

Common noise culprits:

-

elbows too close to the furnace

-

vent termination exposed to wind

-

improper vent sizing

-

vent pipes touching joists

-

vent vibration transmitted to framing

🔧 Samantha’s Noise-Minimization Tips

-

Use long-radius elbows

-

Add pipe insulation between framing contacts

-

Terminate the vent where wind is minimal

-

Use concentric vent kits for smoother airflow

-

Support pipes every 3–4 feet

This can reduce furnace noise by 30–50%.

🧠 12. Samantha’s Complete High-Efficiency Venting Checklist

This is the list she uses on every 96% install:

Vent Pipe Rules

✔ Correct diameter

✔ PVC/CPVC/PP per manufacturer

✔ Slope ¼ inch per foot

✔ Supported every 3–4 ft

✔ Air sealed at wall penetrations

✔ Protected from freezing

✔ Intake/exhaust balanced

✔ Terminated in safe zones

Condensate Rules

✔ Trap installed

✔ Drain sloped

✔ Pump if required

✔ Overflow switch

✔ Freeze protection

✔ Separate furnace/AC traps

Safety

✔ Vent clearances per code

✔ No mixing pipe materials

✔ No long horizontal traps

✔ No shared atmospheric venting

✔ CO detectors near bedrooms

🌟 Conclusion: “A High-Efficiency Furnace Only Delivers High-Efficiency Comfort When the Venting & Drainage Are Done Right.”

Samantha reminds homeowners that great heating isn’t just about equipment — it’s about design:

-

the slope

-

the drain

-

the trap

-

the venting

-

the airflow

-

the freeze protection

-

the pressure balance

It’s all invisible.

But it determines everything.

“Quiet comfort isn’t an accident — it’s what happens when the furnace can breathe and drain the way it was built to.”

When homeowners follow Samantha’s venting and condensate rules, their furnace runs:

-

quieter

-

safer

-

longer

-

more efficiently

-

without stress

And that’s what high-efficiency living is all about.

Buy this on Amazon at: https://amzn.to/4hJt23t

In the next topic we will know more about: Duct Design Mistakes You Only Notice After Installation: Samantha’s Red-Flag List