If you want your PTAC, through-the-wall AC, or heat pump to last 10–20 years, you can’t just choose the right unit — you’ve got to build the right structure around it.

Too many homeowners slap a PTAC sleeve into a random cavity, screw it into drywall, and hope the wall “holds up.” Then they wonder why the room shakes, the unit vibrates, or the sleeve starts pulling away after a few seasons.

Amana Distinctions Model 12,000 BTU PTAC Unit with 3.5 kW Electric Heat

Durability doesn’t come from luck.

Durability comes from load paths, solid framing, proper sleeve support, and vibration isolation.

This guide covers every structural rule I follow before installing any wall-mounted HVAC system. Build the wall right, and the unit will run quieter, last longer, and cost far less to maintain.

Let’s dig in.

🧱 1. Why Structural Design Matters More Than Most Homeowners Realize

Installing HVAC equipment into a wall isn’t like hanging a picture. A PTAC or through-the-wall AC:

-

Vibrates

-

Expands and contracts

-

Pulls inward from suction

-

Pushes outward during fan cycles

-

Gets heavy when condensate accumulates

-

Transfers energy into the studs and sheathing

If the wall isn’t designed to handle that movement, you get:

❌ Noise

❌ Rattling

❌ Warping

❌ Water leaks

❌ Structural cracking

❌ Loose sleeves

❌ Failing anchors

❌ Vibration echoing through the room

Durability starts with structure.

📏 2. Step One — Confirm Wall Type & Load Capacity

Before cutting anything, Mike checks what kind of wall he’s working with.

Common wall types:

✔️ Wood stud walls (most residential)

Best for easy framing and reinforcement.

✔️ Metal stud walls

Require reinforcement to prevent flex.

✔️ Masonry or concrete

Excellent for rigidity but may need sleeve spacers.

✔️ Mixed wall systems (retrofits)

Often need customized framing.

To identify your wall:

-

Tap and listen for hollowness

-

Use a stud finder

-

Check attic/basement framing

-

Remove outlet plates to peek inside

Once you know the wall type, you can calculate the structural needs.

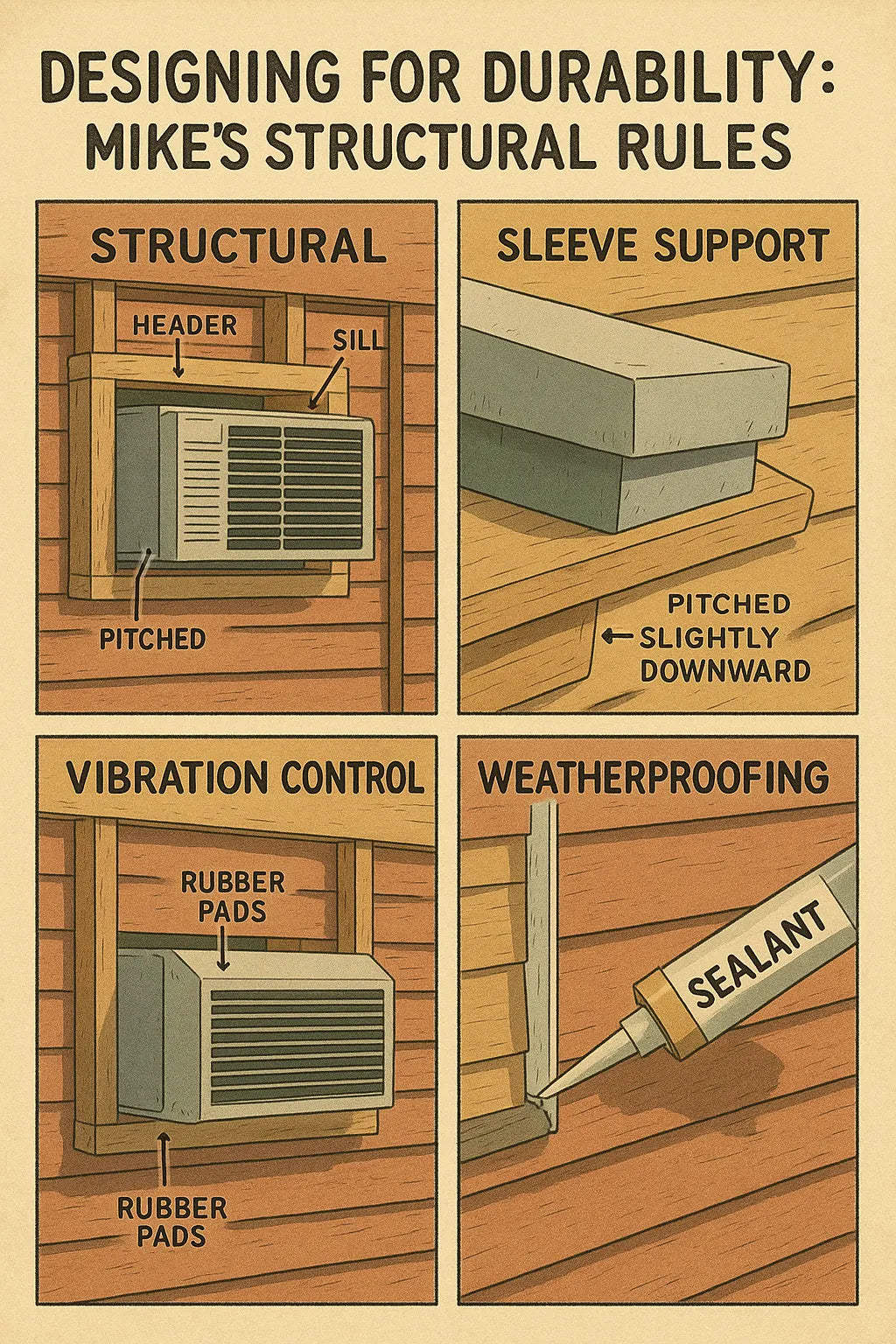

🪚 3. Step Two — Build a True Bearing Frame Around the Sleeve

A PTAC sleeve relies on framing strength, not drywall, to hold it steady.

Mike’s standard is a “four-sided structural frame”:

✔️ Header (top)

A horizontal support beam redistributing weight to studs.

✔️ Sill (bottom)

Supports the sleeve weight and keeps it level.

✔️ King studs (sides)

Full-height studs bracing each edge.

✔️ Jack studs

Additional vertical support under the header.

✔️ Cripple studs

Used below windows or irregular openings.

This creates a mini “window frame” for the PTAC sleeve — solid, square, and load-bearing.

🧰 4. Step Three — Choose the Correct Materials for Long-Term Support

Durability is all about materials that resist:

-

Moisture

-

Movement

-

Thermal expansion

-

Weight

-

Vibrations

Mike’s go-to materials:

✔️ Pressure-treated lumber

For the sill plate or bottom framing.

✔️ Kiln-dried studs

Minimizes warping and shifting.

✔️ Exterior-grade plywood

Provides rigid backing behind the sleeve.

✔️ Galvanized screws

Won’t rust, even near condensation.

✔️ Exterior-grade sealants

Prevent infiltration and moisture intrusion.

✔️ Closed-cell spray foam

Locks gaps without compressing over time.

Avoid interior-grade materials. They deteriorate fast with HVAC moisture.

🔧 5. Step Four — Ensure the Wall Can Handle Sleeve Weight & Movement

A PTAC sleeve doesn’t just sit in the wall — it becomes part of the building structure.

Here’s what to consider:

✔️ Sleeve weight

Typical PTAC sleeves weigh 15–30 lbs.

✔️ Operating weight

Units can reach 100–130 lbs installed.

✔️ Condensate weight

Add several more pounds during peak cooling.

✔️ Torque forces

Fans and blowers create rotational strain.

✔️ Expansion

Metal sleeves expand & contract with temperature swings.

To handle this, Mike reinforces:

-

Sill plates

-

Stud edges

-

Mounting flanges

-

Support brackets

This keeps everything square and prevents long-term wall sagging.

📐 6. Step Five — Get Perfect Level, Pitch & Alignment

Durability collapses when installations are crooked.

Sleeves must be:

✔️ Perfectly level left-to-right

Prevents uneven vibration and fan noise.

✔️ Slightly pitched outward

Usually ¼" downward to allow drainage.

✔️ Squared inside the framing

Anything out of square = friction, noise, and leaks.

✔️ Flush with exterior wall

Prevents internal condensation buildup.

Tools Mike uses:

-

Torpedo level

-

Laser line level

-

Shims

-

Precision square

Incorrect angles cause long-term damage to both the unit and the wall.

🌬️ 7. Step Six — Control Vibration Before It Enters the Structure

Here’s where most installs fail:

Vibration travels through the sleeve and into the studs, which becomes noise inside the room.

To stop this, Mike uses:

✔️ Rubber isolation pads

Placed between sleeve + framing.

✔️ Foam gasket kits

Prevent metal-on-wood contact.

✔️ Vibration-damping tape

Applied to sleeve edges.

✔️ Anti-vibration mounting brackets

Especially for powerful blowers.

✔️ Acoustic caulk

Absorbs vibration instead of reflecting it.

Soundproofing standards reference (ASHRAE noise control)

This alone eliminates 80% of noise issues.

🛡️ 8. Step Seven — Weatherproofing That Protects Your Wall for Decades

Water is the enemy of durability.

A leaking PTAC sleeve can rot studs in 2–3 years.

Mike weatherproofs every install with:

✔️ Exterior-grade flashing

Stops water from entering the sleeve perimeter.

✔️ High-quality silicone sealant

UV-resistant, flexible, long-lasting.

✔️ Expanding closed-cell foam

Seals gaps but never becomes spongey.

✔️ Exterior drip edge

Prevents water from pooling above the sleeve.

✔️ Backer rod

Provides a buffer for sealant to flex.

Resource for weatherproofing best practices

🧊 9. Step Eight — Sleeve Selection Matters for Durability

Sleeves come in different materials:

✔️ Galvanized steel

Strongest and longest-lasting.

✔️ Composite

Good for corrosion resistance; lighter.

✔️ Aluminum

Lightweight but can flex more.

Mike’s rule:

“If you want durability: metal sleeve, reinforced framing, and vibration isolation.”

Sleeve compatibility ensures perfect fit, drainage, and noise reduction.

🛠️ 10. Sleeve Installation Rules That Guarantee Long-Term Stability

Here are Mike’s non-negotiables:

✔️ Fasten sleeve to framing studs — never drywall

✔️ Use 6–8 mounting points minimum

✔️ Seal interior AND exterior

✔️ Add a lightweight backstop to keep sleeve square

✔️ Avoid over-tightening screws (prevents metal bending)

Once installed, Mike always:

✔️ Runs a vibration test

✔️ Checks drainage with 1 cup of water

✔️ Confirms flush alignment

A 10-minute test saves 10 years of headaches.

🔇 11. Reducing Operational Noise Through Better Structural Design

Noise complaints usually stem from:

-

Metal-to-wood contact

-

Uneven framing

-

Loose fasteners

-

High resonance wall cavities

-

Sleeve flexing

Mike solves this with:

✔️ Foam isolation strips

✔️ Rubber gaskets

✔️ Rigid support brackets

✔️ Acoustic mat beneath unit

✔️ Backerboard reinforcement

✔️ Flexible sealant

With proper structure, even high-BTU PTACs run whisper-quiet.

🧭 12. Structural Red Flags That Tell Mike “Do NOT Install Here”

If any of these conditions appear, Mike refuses installation until corrected:

🔻 Rotting studs

🔻 Mold or moisture damage

🔻 Bowed or warped walls

🔻 Insufficient structural depth

🔻 Metal studs without reinforcement

🔻 Electrical or plumbing interference

🔻 Unstable siding or exterior sheathing

🔻 Brick or masonry cracks

🔻 Insufficient exterior drainage slope

Fix the wall first — then install HVAC.

📋 13. Mike’s Durability Checklist (Print This Before Installing)

Structural

-

☐ Studs reinforced

-

☐ Full frame built (header/sill/jacks)

-

☐ Sleeve fits perfectly

-

☐ Sleeve properly pitched

Vibration Control

-

☐ Rubber isolation pads installed

-

☐ Gaskets applied

-

☐ No metal-on-wood contact

-

☐ Unit runs without resonance

Weatherproofing

-

☐ Flashing installed

-

☐ Exterior sealant applied

-

☐ Foam perimeter sealed

-

☐ Drip edge added

Alignment

-

☐ Level side-to-side

-

☐ Pitch outward

-

☐ Flush with exterior

-

☐ No interior gaps

Noise

-

☐ No rattling

-

☐ No flexing

-

☐ No wall echo

-

☐ Airflow smooth

If all these are checked — your system is built for decades.

🎯 Conclusion: Durability Isn’t an Upgrade — It’s the Foundation

A PTAC or through-the-wall AC can only perform as well as the wall behind it.

If the structure is weak, everything else fails.

But if you follow Mike’s rules for:

✔️ Strong framing

✔️ Proper sleeve support

✔️ Vibration control

✔️ Perfect leveling

✔️ Effective weatherproofing

✔️ Correct material selection

Your HVAC system will run quieter, last longer, and deliver better comfort from day one.

You don’t get durability by accident — you design it.

Buy this on Amazon at: https://amzn.to/3WuhnM7

In the next topic we will know more about: The Install Triangle: Mike’s Three-Point Check for Clearance, Power & Drainage Before Picking the Wall