When I decided to install a Daikin 20 Ton 14.2 IEER2 packaged rooftop unit for my building, I assumed the hardest part would be wiring or ductwork. But before a crane even lifted the unit, I learned that clearance and space planning can make or break a project.

This guide walks you through everything I wish I knew ahead of time — from roof load capacity to service clearances, crane lifts, and duct transitions — so you can avoid costly mistakes and delays.

🏗️ The Size & Weight of a 20 Ton Packaged Unit

The first shock? These units are huge.

-

Dimensions: A Daikin 20 Ton packaged rooftop unit is typically 7–8 feet long, 4–5 feet wide, and 4–5 feet tall.

-

Weight: Between 2,000 and 2,500 lbs, depending on options like economizers or factory-installed controls.

-

Impact: This weight sits on a roof curb, so your building’s structure must be able to handle a concentrated load.

👉 My unit weighed just over 2,200 lbs. I had to hire a structural engineer to confirm my roof beams could support it. Without that, my city wouldn’t even issue a permit.

📎 Daikin Applied – Packaged Rooftop Units

📏 Rooftop Structural Requirements

Installing on a roof isn’t just about finding flat space.

Load Calculations

-

Engineers check dead load (weight of unit) + live load (workers, snow, wind).

-

Beams may need reinforcement to prevent sagging.

Roof Curb Prep

-

The roof curb supports the unit and connects it to ductwork.

-

It must be installed, flashed, and sealed in advance to prevent leaks.

Wind & Seismic Considerations

-

In some states, building codes require wind uplift calculations or seismic bracing.

👉 I spent about $3,500 on curb reinforcement and flashing — worth every penny when the first storm hit.

📎 ASHRAE Structural Requirements for Rooftop Units

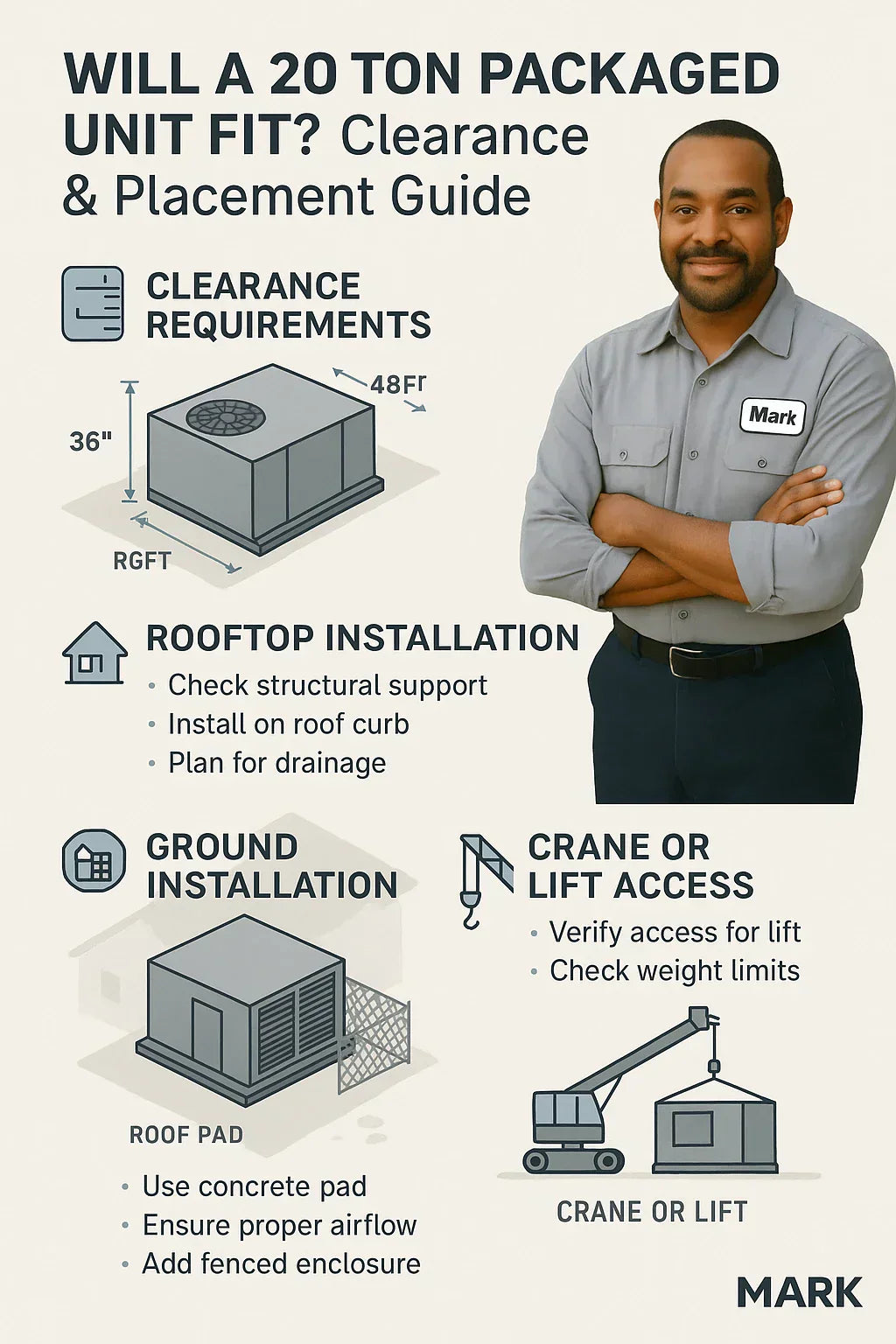

📐 Service Clearances & Access

This is where most first-time buyers slip up. Even if the unit “fits,” can you service it?

Daikin Clearance Guidelines (typical):

-

36 inches minimum on service sides

-

48 inches for coil cleaning access

-

6 feet overhead clearance for vertical discharge fans

-

Unobstructed panel access for electrical compartments

Why It Matters

-

Techs need to open side panels for maintenance.

-

Coil cleaning requires hose access and room for tools.

-

Without space, you’ll pay extra labor because service takes longer.

👉 I initially planned to place my unit near a parapet wall. My contractor pointed out it would block one access panel. I had to move the curb 18 inches to comply.

🏢 Rooftop vs. Ground Pad Installation

Not every 20 Ton unit has to go on a roof. Some buildings use ground pads.

Rooftop Installation

✅ Saves ground space

✅ Reduces vandalism risk

✅ Keeps noise away from tenants

❌ Requires crane lifts (expensive, permit-heavy)

Ground Pad Installation

✅ Easier service access

✅ No crane needed if forklift available

✅ Lower structural cost (no roof reinforcement)

❌ Requires fenced enclosure for security

❌ Needs vibration pads to reduce noise transfer

❌ Must plan condensate drainage carefully

👉 If I had the space, I might have gone ground pad. But in a downtown area, rooftop was my only option.

📎 Energy.gov – Rooftop vs. Ground HVAC Considerations

🚧 Crane & Rigging Considerations

One of the biggest surprises in my install was crane coordination.

What to Plan For

-

Permits: Some cities require street closures. I paid $1,200 for mine.

-

Scheduling: Wind or weather delays add cost. My first lift was canceled due to 20+ mph gusts.

-

Rigging: Use spreader bars and lift lugs to avoid damaging the unit.

-

Safety: Follow OSHA fall protection and lifting protocols.

👉 Lesson learned: Always schedule the crane early in the morning, when winds are calmer and traffic is lighter.

🛠️ Electrical & Ductwork Space Planning

Even if the unit fits, you’ll need space for connections and transitions.

Electrical Access

-

460V 3-phase disconnect switch must be within sight of the unit.

-

Allow space for conduit routing and safe technician access.

Ductwork Transitions

-

Packaged units connect directly to supply and return ducts through the roof curb.

-

Custom sheet metal is often needed to match existing duct sizes.

-

Flexible connectors recommended to reduce vibration.

👉 My contractor built a transition box that extended 18 inches out. If I hadn’t planned clearance for it, the ducts would have interfered with a roof vent.

📎 National Electrical Code (NEC)

💡 Mark’s Checklist Before Ordering

Here’s the exact checklist I used before ordering my Daikin 20 Ton:

-

✅ Structural engineer confirmed roof load

-

✅ Roof curb reinforced, flashed, and sealed

-

✅ Minimum 36–48 inch service clearances measured

-

✅ Crane permit secured and scheduled

-

✅ Electrical service (460V, 3-phase) confirmed

-

✅ Disconnect switch location mapped

-

✅ Duct transitions designed and approved

-

✅ Drainage slope checked (for rooftop condensate runoff)

👉 Following this checklist saved me thousands in rework.

✅ Final Thoughts

Will a 20 Ton Daikin packaged unit fit on your roof or pad? The short answer: probably — but only if you plan for clearance, weight, and access.

For me, space planning was just as important as choosing the right unit. By addressing roof load, clearances, crane access, and duct transitions upfront, my installation went smoothly — and my tenants stayed comfortable without costly downtime.

Bottom line: Measure twice, order once.

In the next topic we will know more about: Do 20 Ton Commercial AC Systems Qualify for Rebates or Tax Credits in 2025?