When my Daikin 20 Ton 14.2 IEER2 rooftop packaged unit stopped cooling properly in the middle of July, I learned the hard way that even the best systems can run into problems. The key is knowing how to troubleshoot quickly, so you can decide what’s a simple fix and what requires a professional.

This guide walks you through the most common cooling issues with large commercial packaged AC units like Daikin’s — based on my own experiences as a building owner, plus best practices from HVAC techs I’ve worked with.

❄️ Symptoms to Watch For

Before you start poking around, identify exactly what your system is doing (or not doing).

-

System running but no cooling – Fans blow, but air is warm.

-

Uneven cooling across zones – Some offices chilly, others sweltering.

-

Short cycling – AC turns on and off rapidly without fully cooling.

-

Unit won’t start – Completely dead or unresponsive to thermostat.

-

High humidity indoors – Feels sticky even when setpoint is reached.

👉 Logging these symptoms helps your HVAC tech narrow down the issue faster.

📎 Energy.gov – AC Troubleshooting Basics

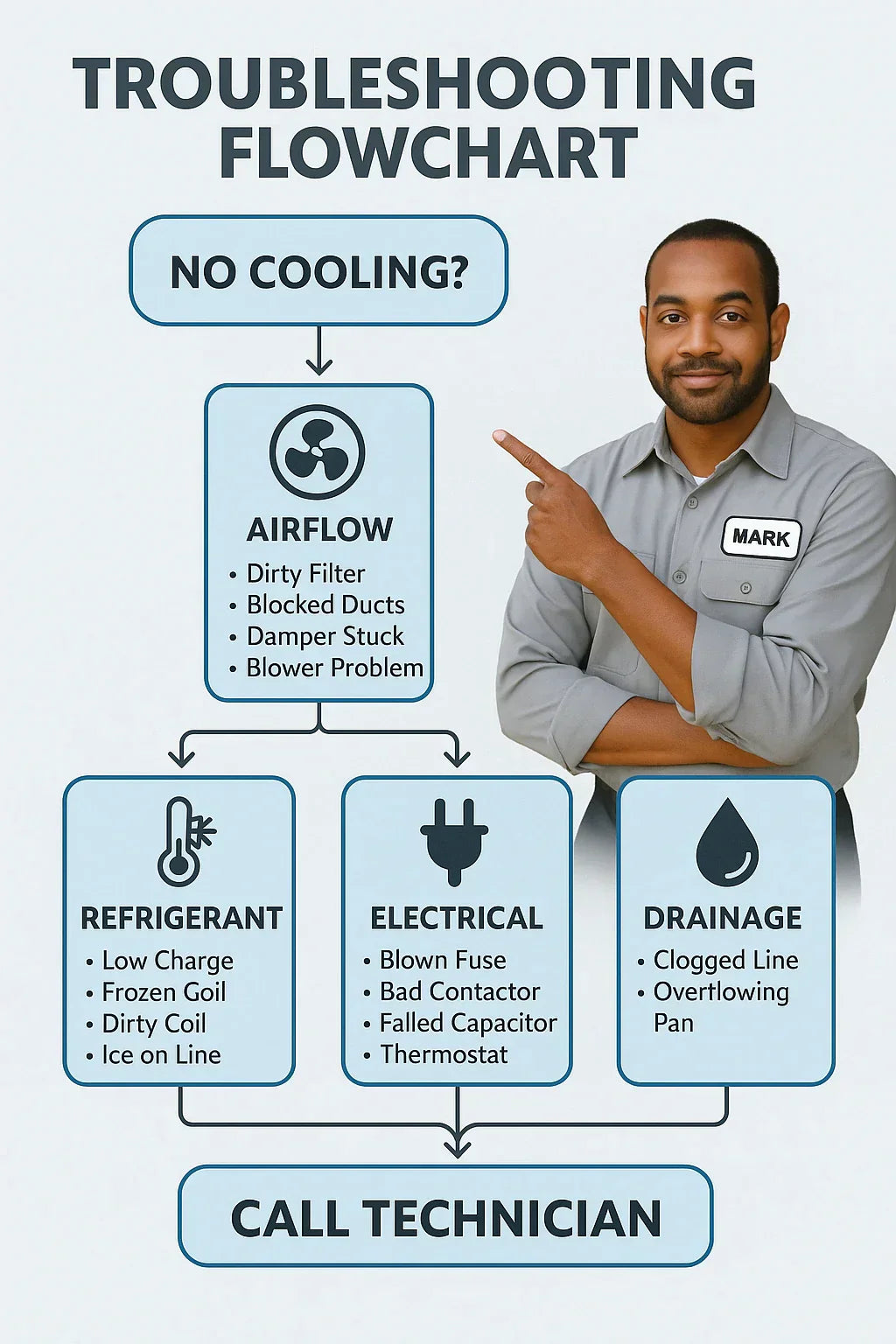

🧽 Airflow Issues

Most rooftop AC problems start with restricted airflow.

Common Causes

-

Dirty filters – The #1 culprit. A clogged filter increases static pressure and reduces cooling.

-

Blocked ducts or registers – Construction debris or insulation collapse can choke airflow.

-

Stuck dampers/economizers – If dampers don’t open, airflow is restricted.

-

Blower belt slip or break – Without the blower fan, no air gets circulated.

Mark’s Experience

I once ignored a belt squeal, and within a week the blower failed completely. The result? My system iced up, and it took a tech half a day to thaw and reset.

📎 ASHRAE Standard 62.1 – Ventilation for Acceptable Indoor Air Quality

🌡️ Refrigerant & Coil Problems

If airflow is fine, the issue may be in the cooling circuit.

Signs of Refrigerant Issues

-

Low refrigerant charge:

-

Warm air from vents

-

Bubbling/hissing at service valves

-

-

Frozen evaporator coil:

-

Ice on refrigerant lines

-

Weak airflow

-

⚠️ Important: Only an EPA-certified technician can legally handle refrigerant.

Coil Problems

-

Dirty condenser coil: Restricts heat rejection → higher head pressure.

-

Dirty evaporator coil: Limits heat absorption → warm supply air.

-

Oil stains on coils: May indicate leaks.

📎 EPA Section 608 Refrigerant Requirements

👉 Lesson I learned: Cleaning coils twice a year prevents 80% of cooling complaints.

🔌 Electrical & Control Failures

Sometimes, the cooling issue has nothing to do with refrigerant — it’s electrical.

Common Failures

-

Blown fuse/tripped breaker – Check both the main panel and the rooftop disconnect.

-

Loose/corroded connections – Vibration can loosen terminals over time.

-

Bad contactor – If contacts are burned, the compressor won’t energize.

-

Faulty capacitor – Weak capacitors cause fans or compressors to struggle starting.

-

Thermostat/BAS miscalibration – Sometimes the issue is as simple as a thermostat set incorrectly.

📎 National Electrical Code (NEC)

👉 My Daikin once “failed to cool,” but it turned out to be a tripped breaker from a power surge. Resetting it solved the problem — but I installed surge protection afterward.

💧 Drainage & Humidity Issues

Even if your unit cools, poor drainage can make the space feel uncomfortable.

Common Problems

-

Clogged condensate drain line – Algae, dirt, or debris cause water backup.

-

Overflow safety switch tripped – Shuts down cooling to prevent leaks.

-

Leaking drain pan – Corrosion can cause water damage.

-

High humidity – Can signal oversized equipment or faulty controls.

👉 I had a drain pan overflow once — water dripped into a tenant’s office ceiling. After that, I added pan tablets every spring.

🔍 Quick DIY Checks Before Calling a Pro

Some issues are simple enough to check yourself:

-

✅ Replace filters

-

✅ Reset breakers and disconnect

-

✅ Inspect for visible ice on coils or lines

-

✅ Confirm thermostat settings (cooling mode, fan auto)

-

✅ Clear debris from condenser intake (leaves, trash, nesting birds)

👉 If these don’t fix it, it’s time to call a licensed HVAC tech.

🧑🔧 When to Call a Technician

These are not DIY fixes — they require a pro:

-

Refrigerant charging or leak repair

-

Electrical component replacement (contactors, capacitors, motors)

-

Compressor failures

-

Recurring breaker trips

-

BAS control logic issues

📎 Daikin Applied – Technical Support Resources

👉 In my case, a frozen coil led to a refrigerant check. My tech found a slow leak at a valve core, repaired it, and recharged the system. Worth every penny.

💡 Mark’s Real-World Lessons

After dealing with a few “not cooling” calls, here are my takeaways:

-

Keep spare filters and belts onsite. Saves hours in downtime.

-

Don’t ignore small noises. A squeak or rattle today = breakdown tomorrow.

-

Always log error codes. Daikin units often display diagnostic codes on their control board.

-

Preventive maintenance prevents 80% of issues. Quarterly contracts are cheaper than emergency calls.

✅ Final Thoughts

A 20-ton Daikin rooftop unit is a workhorse, but no system is immune to problems. The key is knowing what to check yourself and when to bring in a professional.

By staying on top of maintenance and catching small issues early, you’ll keep your building comfortable, your tenants happy, and your utility bills under control.

In the next topic we will know more about: Clearance & Space Planning: Will a 20 Ton Packaged Unit Fit on Your Roof or Pad?