🏢 Introduction: When the Cooling Stops

I’ll never forget the first summer day when our office’s 10 ton AC system suddenly stopped cooling. Phones were ringing, employees were fanning themselves with folders, and I could feel the frustration rising.

Sound familiar?

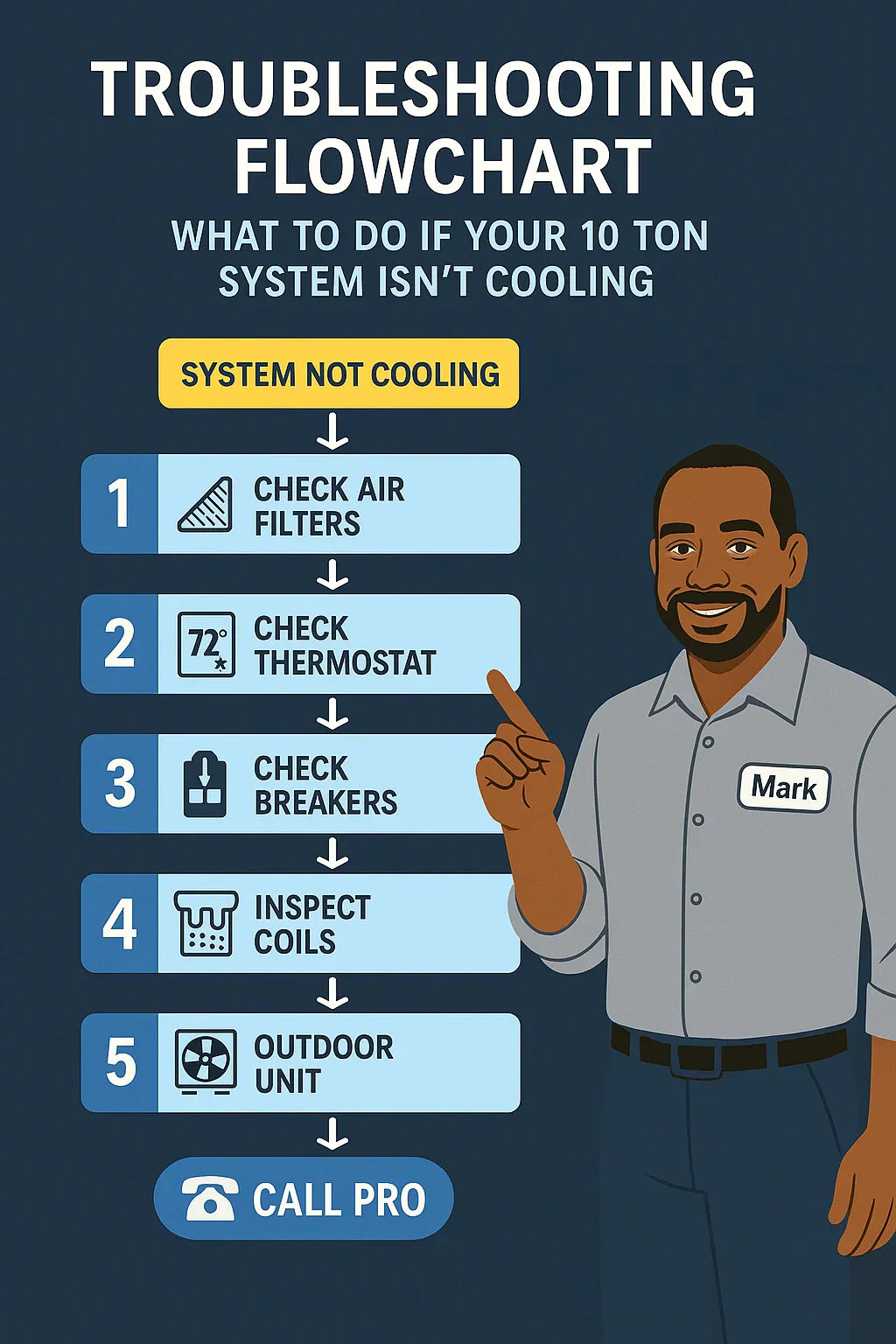

Here’s the good news: not every cooling issue means your system is dead or requires a costly emergency service call. Many times, the problem is simple and preventable—something you can check yourself before calling in the pros.

In this guide, I’ll walk you through the step-by-step troubleshooting process I use whenever a Daikin (or any other 10 ton commercial system) isn’t cooling properly.

🧹 Step 1: Check Air Filters

It may sound too simple, but trust me: dirty filters are the #1 cause of “no cooling” complaints I’ve dealt with.

Why Filters Matter

-

Filters trap dust, pollen, and debris.

-

Over time, they clog and restrict airflow.

-

Reduced airflow = weak cooling, frozen coils, and high energy bills.

What to Do

-

Pull out the return air filters.

-

If they’re gray or covered in dust, replace them.

-

Standard rule: replace filters every 1–3 months depending on use.

📖 See ENERGY STAR filter maintenance guide.

❄️ Step 2: Inspect the Thermostat

If your system isn’t cooling, sometimes the thermostat is the culprit.

Common Issues

-

Someone changed settings (set to heat instead of cool).

-

Wrong setpoint (set to 78°F instead of 72°F).

-

Batteries dead or display blank.

-

Smart thermostats misprogrammed.

Quick Fixes

-

Make sure thermostat is in cool mode.

-

Lower setpoint by at least 3–5°F.

-

Replace batteries if needed.

-

Reset programming or schedule.

📖 ENERGY STAR Smart Thermostats Guide.

🌬️ Step 3: Verify Airflow

Walk through your building and check vents.

What to Look For

-

Are vents blowing air, even if warm?

-

Are some rooms strong and others weak?

-

Any vents blocked by furniture, boxes, or ceiling tiles?

Common Problems

-

Closed dampers: Sometimes accidentally shut during cleaning.

-

Blocked vents: Furniture pushed against supply registers.

-

Collapsed flex duct: Can choke airflow.

Fixes

-

Open dampers fully.

-

Clear obstructions.

-

If airflow is weak everywhere, the blower motor or ductwork may be the issue.

⚡ Step 4: Check Electrical Breakers

Large systems like a Daikin 10 ton pull serious power. Electrical issues can shut the whole system down.

What to Check

-

Go to the breaker panel.

-

Look for tripped breakers labeled “AC” or “air handler.”

-

Reset once if safe.

Warning Signs

-

Breaker trips again immediately—stop and call a pro.

-

Repeated tripping means deeper issues (short circuit, failing motor, overloaded heat kit).

📖 ASHRAE standards require proper electrical inspection during commissioning.

🧊 Step 5: Look for Frozen Coils

One of the clearest signs of trouble is ice buildup on the evaporator coil or refrigerant lines.

Why Coils Freeze

-

Dirty filters restricting airflow.

-

Low refrigerant charge.

-

Blower fan not running.

How to Check

-

Open the air handler access panel.

-

Look for frost or ice on coils or refrigerant lines.

What to Do

-

Shut system off immediately to prevent compressor damage.

-

Replace filters if clogged.

-

Call a licensed HVAC technician if ice persists.

📖 Energy.gov – Maintaining Your Air Conditioner.

🔌 Step 6: Inspect Outdoor Unit

Sometimes the issue isn’t indoors at all—it’s with the condenser outside.

What to Look For

-

Debris blocking airflow (grass, leaves, trash).

-

Fan not spinning.

-

Strange noises (buzzing, clicking, grinding).

Quick Fixes

-

Clear away debris.

-

Listen for compressor running—if silent, could be capacitor or motor.

-

Check disconnect switch is on.

Pro Problems

-

If the outdoor fan isn’t running but the unit hums, the capacitor may be bad.

-

If the compressor won’t start, that’s a professional repair.

📖 HVAC.com – AC Troubleshooting.

🛠️ Step 7: Assess Refrigerant & Leaks

Low refrigerant is a common but serious problem.

Signs of Low Refrigerant

-

Warm air from vents.

-

Frozen coils.

-

Hissing sound near lines.

What to Do

-

Only licensed technicians can add refrigerant.

-

Don’t attempt DIY—it’s illegal and unsafe.

-

If refrigerant is low, find and fix the leak before recharging.

🧾 Common Issues & Quick Fixes

Here’s a cheat sheet for quick diagnosis:

-

Dirty filters → Replace filters.

-

Thermostat wrong mode → Reset settings.

-

Blocked airflow → Clear vents/dampers.

-

Tripped breaker → Reset once, call pro if repeat.

-

Frozen coil → Shut system off, call tech.

-

Outdoor unit blocked → Clear debris.

-

Refrigerant leak → Call licensed contractor.

📖 ACHR News Troubleshooting Guide.

✅ When to Call a Pro

DIY troubleshooting is great, but here’s when to stop and call a licensed HVAC contractor:

-

Refrigerant issues (adding or repairing leaks).

-

Compressor not engaging.

-

Repeated breaker trips.

-

Burnt wiring smells.

-

No airflow even with blower running.

If you push past DIY limits, you risk damaging expensive parts like the compressor, which can cost $3,000–$5,000 to replace.

🧹 Preventive Maintenance to Avoid Future Problems

Troubleshooting is great, but prevention is better.

Seasonal Checklist

-

Spring: filters, coils, refrigerant levels.

-

Summer: thermostat programming, duct balancing.

-

Fall: test heat kit, inspect wiring.

-

Winter: check duct insulation, cycle system occasionally.

📖 ENERGY STAR – Heating & Cooling Maintenance Tips.

📈 Conclusion: Stay Cool with a Plan

If your 10 ton system stops cooling, don’t panic. Start with the basics: filters, thermostat, airflow, breakers, and coils. Many problems are simple fixes that save you time and money.

But know your limits. When it comes to refrigerant, compressors, or repeated electrical failures, call in a pro. The faster you address problems, the less costly they become.

Mark’s takeaway: “Troubleshoot what you can, but don’t ignore the signs of a bigger issue. Your comfort—and your wallet—depend on acting fast.”

In the next topic we will know more about: Will a 10 Ton Multi-Positional System Fit in Your Mechanical Room?