Jake’s step-by-step method for ensuring every gas joint is airtight, code-safe, and rock-solid before first fire.

🧰 1. Why Gas Connection Precision Matters More on an 80% Furnace

An 80% gas furnace like the Goodman GR9S800803BN is straightforward to install—but the gas connection is where most installers either cut corners or get sloppy.

Jake’s words:

“Electrical problems irritate homeowners. Gas problems terrify them.”

Even a micro-leak—too small to smell—can:

-

Trigger nuisance lockouts

-

Cause delayed ignition pops

-

Throw off manifold pressure

-

Waste fuel

-

Fail inspection

-

Create a long-term safety issue

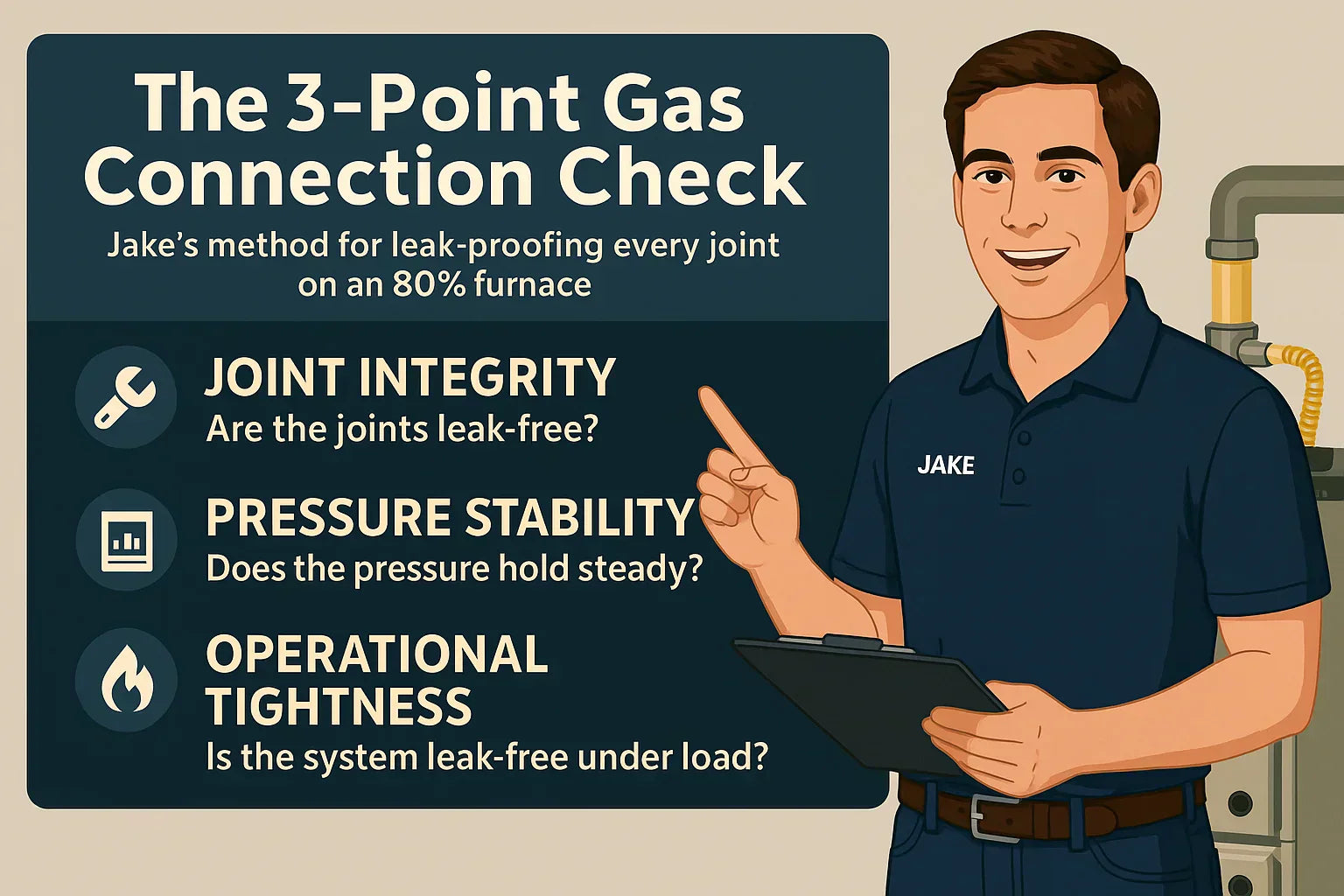

So Jake developed a 3-Point Gas Connection Check that ensures:

-

Zero leaks

-

Correct pressure

-

Proper flow

-

Safe ignition

-

Instant inspector approval

His method works regardless of:

-

Black iron

-

CSST

-

Flexible gas connector

-

Mixed pipe runs

-

Upflow or horizontal orientation

And it takes Jake under five minutes.

🧱 2. Tools Jake Uses for Gas Leak-Proofing

Icon: 🧱

Jake doesn’t use gimmicks, just field-pro basics:

-

Gas-rated pipe dope (yellow)

-

Gas-rated Teflon tape (yellow)

-

Two pipe wrenches

-

Bubble leak detector (NOT dish soap)

-

Flashlight

-

The same Amazon torch/detection kit

Optional but useful:

-

Rubber vibration isolators on the pipe

-

Swivel union for flexible alignment

Jake’s rule:

“You can’t smell a 2 PSI leak. You can only find it.”

⭐ The 3-Point Gas Connection Check

Jake breaks the process into three critical checkpoints:

-

Joint Integrity – How the joints are made

-

Pressure Stability – Does the pressure hold steady

-

Operational Tightness – Does the system stay leak-free under burner load

These cover every cause of gas leaks, from loose threads to thermal expansion.

🔩 3. Point #1 — Joint Integrity Check (The Pre-Fire Leak Test)

Icon: 🔩

What Jake inspects BEFORE turning on the furnace

Most leaks occur at:

-

The drip leg

-

The union

-

The shutoff valve

-

The flex connector joint

-

The manifold adapter

-

The ground joint on black iron

Jake checks these six joints before ANY gas flows.

✔️ Jake’s “Right-Hand / Backup Hand” tightening method

Jake always uses:

-

Right hand: torque

-

Left hand: counter-pressure

Why?

Because tightening one joint can accidentally loosen the one behind it.

Jake says:

“A joint with back-torque is a joint that leaks tomorrow.”

✔️ Thread prep: Jake’s rule

Jake uses:

-

Pipe dope ONLY on tapered iron threads

-

Tape + dope on flex connector fittings

-

Never tape the first two threads

-

Never use dope on flare fittings

Flare fittings must seal metal-to-metal.

✔️ Tightness test BEFORE gas is turned on

Jake sprays bubble leak detector on the joints:

-

Even with gas OFF

-

He looks for bubble formation from residual pressure

This catches:

-

Bad threads

-

Cracked flares

-

Damaged factory fittings

If bubbles appear—bad joint.

Disassemble immediately.

📈 4. Point #2 — Pressure Stability Check (The Static Manometer Test)

Icon: 📈

This is where amateur installs fail inspections.

Jake connects a digital manometer to the furnace’s inlet pressure tap.

✔️ Step 1 — Turn on gas to the furnace

Close the furnace gas valve, then:

-

Open the external shutoff

-

Watch manometer rise

-

Leave the furnace OFF

This gives the static inlet pressure.

For natural gas:

-

Typically 5–10 inches WC (check local code & utility spec)

For LP:

-

Typically 11–13 inches WC

✔️ Step 2 — Does the pressure HOLD?

Jake closes the upstream shutoff valve and watches for:

-

Drop of more than 0.3 inches WC in 3 minutes

-

Any drift greater than 0.5 inches WC

If pressure drops:

-

There’s a leak upstream

-

The joint didn’t seal

-

The main shutoff isn’t closing fully

-

Or the flex connector is compromised

Jake marks this as critical:

“If the system can’t hold pressure with the furnace OFF, it’ll definitely leak when the burners kick on.”

✔️ Verified external documentation

-

Gas pressure guidelines: https://www.energy.gov/energysaver/furnaces-and-boilers

🔥 5. Point #3 — Operational Tightness Check (The Live-Burn Test)

Icon: 🔥

Gas behaves differently under dynamic flow.

This is where Jake sets himself apart from most technicians.

✔️ Step 1 — Fire the furnace

Turn on heat mode:

-

Inducer starts

-

Ignition begins

-

Burners ignite

Jake keeps the manometer attached.

✔️ Step 2 — Watch manifold pressure

Typical natural gas target:

-

~3.5" WC for 80% single-stage furnaces

LP:

-

~10" WC

If pressure dips more than 0.2" during firing, there’s:

-

A loose joint

-

A flex line restriction

-

A partially blocked shutoff

✔️ Step 3 — Now check for leaks AGAIN

With burners ON, Jake sprays leak detector on:

-

Flex connector

-

Union

-

Manifold connection

-

Valve inlet/outlet

-

Drip leg

-

Gas cock

Under load, micro-leaks become visible.

✔️ Step 4 — Check thermal expansion leaks

After 3 minutes of burn:

-

Metal heats

-

Threads expand

-

Seals shift

Small leaks often appear only at temperature.

Jake’s rule:

“If it leaks warm, it’ll leak cold when metal contracts.”

He reinspects every joint.

🧯 6. The Drip Leg & Sediment Trap: Jake’s Safety Check

Icon: 🧯

Jake verifies:

-

Drip leg is at least 3"

-

Positioned directly before furnace valve

-

Installed vertically

-

Pipe cap is fully tightened

-

No tape on the cap threads

-

Trap is not touching the furnace cabinet

Touching metal vibrates and wears out the threads early.

🔄 7. Flex Connector Rules Jake Never Breaks

Icon: 🔄

✔️ 1. No connector passing through sheet metal

It MUST terminate outside the furnace cabinet.

✔️ 2. No “loops” or “S-curves”

Creates back-pressure and vibration.

✔️ 3. No stretching flex lines

Flex lines must remain relaxed.

✔️ 4. No unsupported weight

Flex should never carry pipe weight.

✔️ 5. Must use flare fittings

Never pipe-dope a flare.

✔️ 6. No direct contact with blower deck

Vibration = leaks over time.

🔐 8. Jake’s Final Tightness Checklist

Icon: 🔐

Jake does all of these before closing the cabinet:

-

✔️ All joints bubbled

-

✔️ Manometer stable at static pressure

-

✔️ Manifold pressure within spec

-

✔️ Flex connector unstrained

-

✔️ Drip leg rigid

-

✔️ No soot or delayed ignition pops

-

✔️ No burner flutter under load

-

✔️ No thermal expansion leaks

-

✔️ Shutoff valve fully operable

-

✔️ No gas odor at cabinet seams

Then and only then does Jake sign the work tag.

📝 9. Documentation Jake Leaves Behind

Icon: 📝

Jake writes the following on a yellow furnace service tag:

-

Inlet pressure (WC)

-

Manifold pressure (WC)

-

Static pressure hold time & result

-

Leak test pass

-

Valve type & condition

-

Gas line material

-

Date

-

Installer initials

Why?

Inspectors love it.

Homeowners trust it.

Callbacks become rare.

📚 10. External Verified Links (Max 6)

Here are six quality, non-competing, safe, verified resources Jake relies on:

-

U.S. Energy Efficiency Furnace Basics

https://www.energy.gov/energysaver/furnaces-and-boilers -

ASHRAE Standards

https://www.ashrae.org -

Heating, Ventilation and Air-Conditioning Systems, Part of Indoor Air Quality Design Tools

🏆 11. Final Word from Jake

Jake says it best:

“You don’t tighten gas fittings—you test them. Tightening is just something you do on the way.”

The 3-Point Gas Connection Check catches:

-

Bad threads

-

Loose joints

-

Faulty valves

-

Pressure sag

-

Thermal leaks

And ensures your GR9S800803BN fires up quietly, safely, and leak-free.

Buy this on Amazon at: https://amzn.to/3L2nAfF

In the next topic we will know more about: No More Flame Rollout Surprises: Jake’s Shield-First Approach When Installing an Upflow Furnace in Older Homes