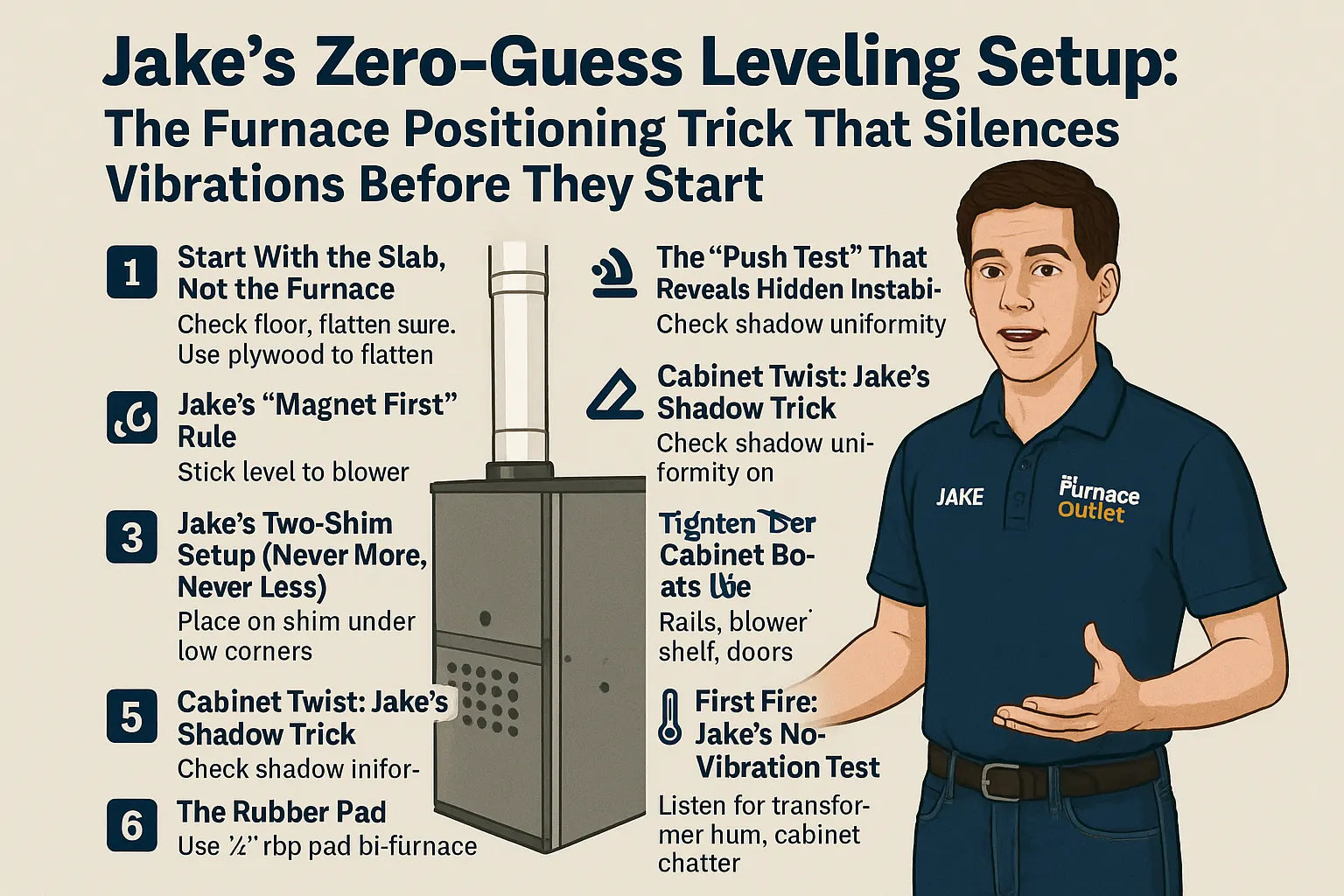

How a $12 tool and a 90-second positioning method can turn a noisy furnace into a silent machine.

🧰 1. Why Leveling Matters More Than Most Installers Think

If your furnace is humming, buzzing, or vibrating louder than a fridge with a bad compressor, 9 times out of 10, the problem started before the wire nuts even came out of the bag.

Jake says it all the time:

“Furnaces don’t vibrate because they’re cheap. They vibrate because somebody skipped the level.”

The Goodman GR9S800803BN, like all single-stage 80% furnaces, sits on:

-

A thin steel cabinet

-

A high-RPM blower assembly

-

A burner compartment that amplifies resonance

-

A return drop that transfers vibrations into the house

If that cabinet is even ¼ inch out of level, the blower housing torques, the burners hum, and the sheet metal becomes a drum.

80,000 BTU 80% AFUE Upflow/Horizontal Single Stage Goodman Gas Furnace - GR9S800803BN

So Jake developed a zero-guess positioning method that removes the guesswork and eliminates vibration before the power is even turned on.

And the beauty?

You need one cheap Amazon level and two shims.

📦 2. Tools Jake Uses (and Why They Matter)

Jake doesn’t show up with a truck full of lasers.

He shows up with the same $12 tool anyone can buy:

-

Mini Magnetic Torpedo Level

Why this one?

-

It’s compact enough to sit on furnace rails

-

The magnet holds perfectly on the blower deck

-

The pitch vial gives a fast vertical reading

-

It’s accurate enough that Jake trusts it with gas appliances

Other items:

-

Composite shims (won’t compress over time)

-

1 plywood slab (if installing on concrete)

-

½” rubber isolation pad

-

Work light (to cast directional shadows that reveal twist)

That’s it.

No lasers.

No gimmicks.

🔎 3. Step 1 — Start With the Slab, Not the Furnace

Jake always inspects the floor first.

A furnace can only be as stable as what it sits on.

✔️ If you’re installing on concrete:

Check for:

-

Crowned center

-

Low corner

-

Thin settling cracks

-

Slab that slopes forward toward the burner door

Jake’s rule:

“If the slab is off more than ⅜ inch, the slab—not the furnace—needs correcting.”

He uses a ¾” plywood pad to flatten irregular concrete, then places a rubber isolation mat on top to absorb harmonics.

✔️ If installing on a platform:

Check:

-

Screw penetration (no wobble)

-

Platform sag

-

Return-air penetration cutouts that weaken rigidity

-

Whether the platform has a slight front dip

Jake adds two cross braces if he sees platform flex.

🧲 4. Step 2 — Jake’s “Magnet First” Rule

This is where Jake gets clever.

Instead of placing the level on the cabinet (which can be warped from shipping), Jake sticks the magnetic level directly on the blower deck.

Why?

Because the blower deck is:

-

Factory-welded

-

Uniform

-

Perfectly square to the furnace rails

If the deck is level, the furnace is level.

Jake’s deck-leveling points:

-

On upflow installs: place the level on the center rail

-

On horizontal installs: place it on the blower housing lip

-

Always check both front-to-back and left-to-right

The deck becomes your reference plane.

No guesswork.

🪜 5. Step 3 — Jake’s Two-Shim Setup (Never More, Never Less)

Jake hates “shim stacks.”

Five random shims under one corner guarantee vibration.

His method:

-

Identify the lowest corner (the level will tell you).

-

Insert one composite shim—not stacked—under that corner.

-

Re-check blower deck.

-

If more adjustment is needed, remove the shim and replace with a single thicker shim, not multiples.

Jake says:

“If your furnace is sitting on more than two shims, your floor is the problem—not the furnace.”

Ideal setup:

-

1 shim on the low side

-

1 shim on the secondary low corner

-

No more than that

This ensures equal weight distribution and no pivot points.

✋ 6. Step 4 — The “Push Test” That Reveals Hidden Instability

Jake lightly pushes the furnace on:

-

The top right corner

-

The blower door

-

The return side

If the furnace rocks even 1–2 millimeters, it will vibrate under load.

Corrective action:

-

Tighten platform

-

Add screw shank fillers

-

Re-seat shims

-

Add reinforced rubber pad

Jake’s rule:

“If I can make it move with two fingers, the blower will move it with two thousand RPMs.”

🎯 7. Step 5 — Cabinet Twist: Jake’s Shadow Trick

Even if the deck is level, the cabinet can still be twisted.

Jake uses a work light to cast shadows along:

-

The top front edge

-

The upper rails

-

The burner compartment lip

Shadows should be uniform.

If the shadow thickens on one side, the cabinet is twisted.

How Jake fixes twist:

-

Loosen platform screws

-

Shim the twist corner

-

Confirm the shadow becomes uniform again

This takes 30 seconds and eliminates long-term vibration.

🔊 8. Step 6 — The Rubber Isolation Pad for Silent Operation

Jake uses a ½-inch rubber HVAC isolation pad under the entire furnace footprint.

This reduces:

-

Cabinet resonance

-

Blower harmonics

-

Return-box vibration transfer

-

Gas-line hum transmission

Rubber = fewer callbacks.

And rubber pads are recommended by both:

-

ASHRAE: https://www.ashrae.org

-

Energy.gov furnace installation best practices: https://www.energy.gov

🌀 9. Step 7 — Align Furnace to the Return Drop (Critical for Noise)

Most installers align the furnace visually.

Jake aligns it to the airflow path, not the walls.

If the return drop is misaligned by even an inch:

-

The blower pulls air unevenly

-

The wheel develops micro wobble

-

The furnace vibrates on high heat rise

-

You get “return rumble” in the hallway

Jake checks:

-

Drop center to blower center

-

Filter rack alignment

-

Cabinet-to-boot engagement

He adjusts positioning so the blower pulls centrally through the return.

This is a major noise reducer.

🔧 10. Step 8 — Tighten Cabinet Points in the Correct Order

Loose cabinet screws equal vibration.

But most people tighten in random order.

Jake’s order (always):

-

Rails

-

Burner compartment

-

Blower shelf

-

Return transition

-

Top plate

-

Cabinet doors last

Why this order?

Because torque on lower screws shifts upper alignment.

This prevents “buzz zones” and door chatter.

🌡️ 11. Step 9 — First Fire: Jake’s No-Vibration Test

Jake runs the furnace with:

-

Blower door on

-

Supply plenum open

-

Filter installed

He listens for:

-

Transformer hum

-

Blower-wheel resonance

-

Flame carrier noise

-

Cabinet chatter

-

Motor whine

If anything is louder than a bathroom exhaust fan, he stops immediately and checks:

-

Deck level

-

Cabinet twist

-

Return alignment

-

Door seating

-

Furnace-to-platform engagement

Correcting positioning usually solves 90% of issues.

📚 12. External Resources Jake Recommends

🏁 13. Final Word From Jake

Jake says it best:

“If the furnace is level, it’s quiet. If it’s quiet, the customer thinks you’re a genius.”

This zero-guess setup eliminates:

-

Vibrations

-

Cabinet buzz

-

Blower hum

-

Return roar

-

Long-term metal fatigue

And best of all — you can do the entire leveling process in under 3 minutes once you master Jake’s method.

Buy this on Amazon at: https://amzn.to/3L2nAfF

In the next topic we will know more about: The 3-Point Gas Connection Check: Jake’s Method for Leak-Proofing Every Joint on an 80% Furnace