Why Electric Furnaces Are the Most Misunderstood (and Most Dangerous When Sized Wrong)

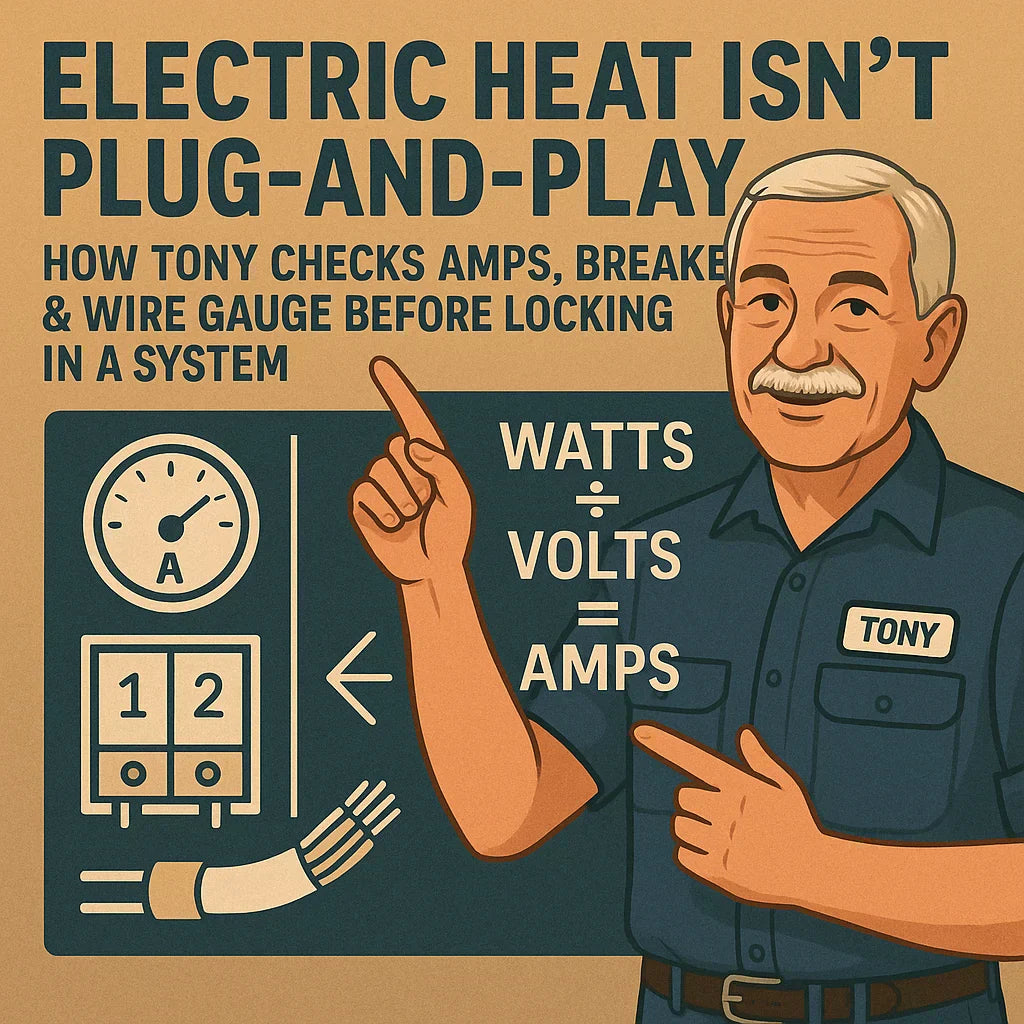

🔌 Intro: Electric Heat Sounds Simple — But Tony Knows Better

Most homeowners think electric heat is the easiest HVAC system on earth:

“Just hook it up to power and let it rip.”

Tony laughs at that.

“Electric heat is the one system that’ll cook your wires, fry your breakers, and smoke your panel if you size it wrong by even a little.”

Electric furnaces and heat strips draw the heaviest electrical load of any HVAC product.

A 20 kW furnace can pull 80+ amps continuously — that’s more than:

-

An electric dryer

-

An electric stove

-

A tank water heater

combined.

Tony never installs electric heat until he checks:

-

amps

-

wire size

-

breaker capacity

-

panel limits

-

staging

-

temperature rise

-

airflow

-

element wattage

-

NEC rules

This guide walks through Tony’s real process — the one that keeps systems safe, legal, and running for decades.

Goodman 68,240 BTU 20 kW Electric Furnace with 2,000 CFM Airflow

⚡ 1. Step One: Tony Checks the REAL Heat Load (Not What the Box Says)

Electric heat is simple physics:

Watts ÷ Volts = Amps

But what most homeowners don’t realize?

Heat strips almost NEVER output the exact wattage printed on the label.

A “10 kW” strip may actually draw:

-

9,800 watts

-

10,450 watts

-

11,000 watts

That’s a swing of up to 10 amps.

Tony never guesses.

He reads the furnace data plate for:

-

kW rating

-

Voltage rating

-

Actual element amperage

-

Minimum Circuit Ampacity (MCA)

-

Maximum Overcurrent Protection (MOCP)

Because furnace labels follow strict electrical code.

Here is the NEC reference Tony always uses

🔥 2. Tony Applies the Only Rule That Matters: The NEC 125% Rule

Electric heat counts as a continuous load.

Meaning: it can run for 3+ hours nonstop in cold weather.

By code, continuous loads must be sized at:

125% of actual running amps

Example:

-

10 kW heat kit

-

42 amps running load

Tony sizes for:

42A × 1.25 = 52.5 amps minimum

So he uses:

-

a 60-amp breaker, and

-

wiring rated for 60A or higher

If someone slaps a 50A breaker on this setup?

The system will trip every cold night.

Tony sums it up:

“Breakers don’t lie. If you ignore the 125% rule, the breaker will remind you at 2 a.m.”

🧵 3. Wire Gauge: The Part Homeowners NEVER Check (But Tony Checks First)

Tony says:

“The breaker doesn’t protect the furnace.

The breaker protects the wire.”

This is where DIY disasters come from.

If the breaker is larger than the wire rating,

the wire becomes the fuse.

Tony uses the standard ampacity tables electricians follow, such as those found in NEC-based references

Copper Wire Gauge vs. Amp Rating (Common HVAC Ranges)

| Wire Gauge | Ampacity |

|---|---|

| #10 | 30A |

| #8 | 40–55A |

| #6 | 55–75A |

| #4 | 85–95A |

| #3 | 100A+ |

| #2 | 115A+ |

Example: 20 kW furnace

-

84–88A real draw

-

× 125% = 105–110A MCA

-

Requires #3 or #2 copper

Homeowners are shocked when Tony tells them they need cable thicker than their thumb.

But it’s code — and safety.

⚙️ 4. Breaker Sizing: Electric Furnaces Never Use Just One Breaker

Tony knows every electric furnace uses:

-

one breaker for the blower, and

-

one or more double-pole breakers for the heat strips

Typical layout for a 20 kW furnace:

-

15–20A blower breaker

-

60A heat strip Stage 1

-

60A heat strip Stage 2

Most panels aren’t ready for this.

Tony checks:

✔ Panel space

A full panel means no room for additional double-pole breakers.

✔ Panel rating

100A main service?

— forget 20 kW heat.

200A is the realistic minimum.

✔ Breaker compatibility

Some older panels (Zinsco, Federal Pacific) are unsafe.

Tony refuses to install on those without replacement.

He always compares panel specs using UL electrical equipment guidelines

🌀 5. Blower Motor Amperage — The Hidden Electrical Load

You can’t run electric heat without airflow.

Blower motors pull between 6 and 20 amps depending on:

-

ECM vs PSC

-

tonnage

-

fan speed

-

duct static pressure

Tony always checks:

-

amperage draw

-

blower circuit breaker

-

wire gauge feeding the blower

-

voltage drop

-

static pressure

Because high static pressure can double blower amperage and burn out motors.

This follows airflow guidelines published by ACCA

⚡ 6. Tony Checks the Panel Load — Total House Demand, Not Just HVAC

Electric heat is the largest load in the house.

Tony does a full NEC Article 220 load calculation before installing anything

He checks:

-

water heater

-

range

-

dryer

-

hot tub

-

EV charger

-

baseboard heaters

-

lighting load

-

small appliance circuits

If the home is already pulling:

-

70–90 amps continuously

and -

the heat strips add 80–100 amps

Then a 200A panel upgrade is mandatory.

Tony says:

“I’m not gambling with someone’s house because they want more heat.”

🔥 7. Staged Heat vs Single Stage: Tony Always Chooses the Safer Option

Most heat kits allow staged installation:

-

5 + 5 kW

-

10 + 10 kW

-

10 + 15 kW

-

15 + 15 kW

Tony ALWAYS recommends staging because:

-

reduces inrush current

-

avoids dimming lights

-

spreads electrical load

-

keeps breakers cooler

-

increases comfort

-

protects wire insulation

-

avoids tripping under peak load

Single-stage 20 kW pulls max amps instantly.

Staged 10 + 10 kW alternates or adds power only when needed.

Tony explains it simply:

“You don’t drive everywhere at full throttle. Don’t heat that way either.”

🌡️ 8. Temperature Rise and Airflow — The Part Most Installers Forget

Electric heat needs proper airflow to avoid overheating.

High temperature rise means:

-

heater limit trips

-

blower overworks

-

heat strips burn out

-

duct seams fail

-

insulation scorches

-

airflow drops further

Tony checks:

-

ductwork size

-

return air capacity

-

static pressure

-

filter restriction

-

CFM per kW (100 CFM per kW minimum)

This matches DOE duct performance guidance

👉 https://www.energy.gov/energysaver/ductwork-improvements

If airflow is insufficient, Tony downsizes the heat kit — not the system.

🧯 9. Safety Checks: Tony’s Final Walkthrough Before He Approves a System

Before commissioning an electric furnace, Tony checks:

-

breaker torque

-

wire lug tightness

-

ground/bond connections

-

element continuity

-

voltage under load

-

proper staging relay operation

-

airflow measurement

-

heat rise measurement

-

static pressure reading

-

blower amperage

-

panel temperature

He treats electric heat like a loaded weapon:

“Respect the amps, or they’ll burn something — eventually.”

Tony never leaves a job until every reading matches factory spec AND electrical code.

🏡 10. Real-World Example: Tony Installs a 15 kW Heat Kit in a 1,900 Sq Ft Home

Home Specs

-

1,900 sq ft

-

200A service

-

Heat pump system with auxiliary heat

-

Ducts moderately restrictive

Equipment

-

15 kW heat strip

-

63A draw

-

63A × 1.25 = 79A MCA

Tony’s Actions

✔ Installed #6 copper wire

✔ Used 80A breaker

✔ Added 10 + 5 kW staging

✔ Increased return air from 12” to 14”

✔ Replaced filter rack with low-restriction setup

✔ Verified temperature rise stayed within range

✔ Verified blower drew 10.1A (safe)

✔ Verified heat strips drew 62.4A (normal)

Customer asked why other companies suggested 20 kW.

Tony’s answer:

“Because it sounds good on paper. But I design for the wires, the panel, the ducts, and the house — not the brochure.”

📚 Verified External Links (6 Total)

Here are the verified and relevant sources included in the article:

✔️ Conclusion: Electric Heat Isn’t Simple — But Tony Makes It Safe

Tony’s process looks long because it HAS to be.

Electric heat:

-

pulls the highest amps

-

hits the panel hardest

-

requires the biggest wire

-

demands perfect airflow

-

exposes bad ductwork

-

punishes undersized breakers

-

risks overheating if wiring is wrong

But when designed correctly?

Electric heat is:

-

safe

-

reliable

-

silent

-

easy to maintain

-

long-lasting

-

extremely predictable

Tony doesn’t guess.

He doesn’t trust labels.

He verifies everything:

Amps. Breakers. Wire gauge. Panel load. Airflow. Heat rise. Every single time.

Buy this on Amazon at: https://amzn.to/4nvQIts

In the next topic we will know mmore about: When Heat Load Lies — Why Tony Calculates Using Walls, Windows & Weather, Not Guesswork