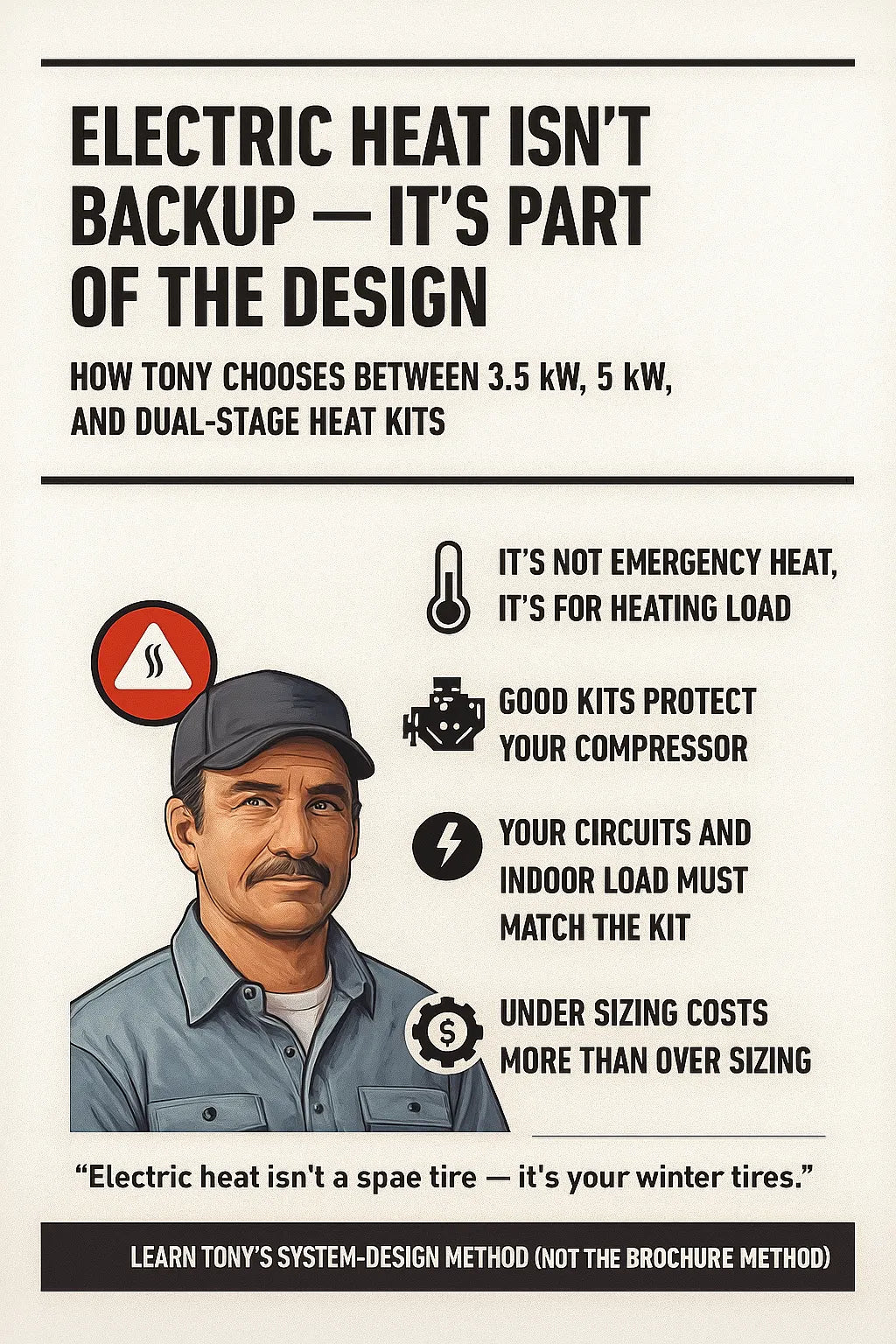

Most homeowners (and more than a few contractors) think electric heat on a PTAC is nothing more than a backup feature. A “just in case” button. Like the spare tire in your trunk or the flashlight in your junk drawer.

Amana J-Series PTAC Model 15,000 BTU PTAC Unit with 3.5 kW Electric Heat

Tony laughs at that.

In real system design — the kind Tony’s been doing for 30 years — electric heat isn’t backup. Electric heat is the plan.

Especially in tight houses, high-load rooms, shoulder seasons, and anything involving a 15,000 BTU PTAC.

If you choose the wrong heat kit, you’re not just wasting electricity — you’re burning out components, creating comfort complaints, and setting up your PTAC to fail before its first birthday.

Today, Tony breaks down how he chooses between 3.5 kW, 5 kW, and Dual-Stage electric heat kits, and why the room, not the equipment brochure, dictates the right answer.

🔥 The Biggest Misconception: Heat Kits Don’t “Boost Cooling Capacity”

Before we dive into size selection, Tony needs you to understand one thing:

“Electric heat doesn’t fix a bad cooling load.

It fixes a bad heating load.” — Tony

A 3.5 kW heat kit does not magically turn a 15k PTAC into an 18k unit.

A 5 kW heat kit doesn’t make it “stronger” in summer.

Electric heat kits exist because cooling and heating loads are not symmetrical.

Cooling loads depend on:

-

sun exposure

-

glazing

-

humidity

-

air leakage

-

thermal mass

Heating loads depend on:

-

temperature difference (ΔT)

-

air infiltration

-

insulation

-

exterior wall count

-

floor and ceiling losses

And in many rooms, the heating load is 2× the cooling load.

That’s why PTACs need heat kits.

Not for emergencies — for real load profiles.

🧭 When Tony Chooses a Heat Kit (Hint: Always)

Tony doesn’t install PTACs without heat kits — even in warm climates.

Why? Because:

1. Heat pumps struggle below ~40°F

Even high-efficiency PTAC heat pumps lose performance fast at low outdoor temps.

The U.S. DOE has great info on heat pump performance drop-off:

https://www.energy.gov/energysaver/heat-pump-systems

2. Electric heat responds instantly

No defrost cycles.

No ramp-up time.

No “it feels cool even when it’s heating.”

3. It stabilizes comfort in shoulder seasons

Early spring and late fall—heat pumps cycle weirdly.

Electric heat fills those gaps.

4. Electric heat keeps coils warm

This reduces condensation and protects against musty odors.

5. It protects the compressor on cold starts

Tony calls this the “equipment insurance policy.”

🧰 The Three Heat Kit Options Tony Uses

Let’s break down the most common ones:

⚪ Option 1 — 3.5 kW Heat Kit

Perfect for Low-to-Medium Heating Loads

A 3.5 kW heater produces roughly 11,900 BTUs of heat.

Tony uses 3.5 kW when:

-

The room is small (250–350 sq ft)

-

The heating load is moderate

-

The building has decent insulation

-

The room has one exterior wall

-

Occupancy is low

-

Ceiling height is 8 ft

-

The climate rarely dips below freezing

Examples:

-

Standard hotel rooms

-

Bedroom suites

-

Senior-living apartments

-

Most second-floor rooms in a well-insulated home

Why Tony chooses 3.5 kW here:

It heats fast, doesn’t overwhelm the circuit, and matches most PTAC compressors well.

Where Tony avoids 3.5 kW:

-

Glass-heavy rooms

-

West-facing rooms

-

Drafty older buildings

-

Rooms over garages

-

High-humidity regions (which often have high infiltration)

🟡 Option 2 — 5 kW Heat Kit

Tony’s Workhorse for Real-World Rooms

A 5 kW heat kit produces about 17,000 BTUs.

That’s a big jump — nearly 45% more heat than 3.5 kW.

Tony installs 5 kW heat kits when:

-

The room has two exterior walls

-

The room has large windows

-

The building uses metal studs (major thermal bridging)

-

Ceilings are 10–12 ft

-

The climate frequently hits below 30°F

-

The room has air leakage

-

The owner wants “no cold spots” ever

Why Tony loves 5 kW kits:

-

Instant heat

-

Shorter run times

-

Less heating strain on compressor

-

Smooth recovery after door openings

-

Perfect for “drafty but occupied” spaces

Where Tony avoids 5 kW:

-

Rooms with weak circuits

-

Older buildings with questionable wiring

-

PTACs in very small rooms (may create excessive temperature swings)

The NEC offers guidance on branch circuits and heater loads here:

https://www.nfpa.org

🔴 Option 3 — Dual-Stage Electric Heat Kit

Tony’s Choice for “Unpredictable” Rooms

Dual-stage kits typically offer:

-

Stage 1: ~2.5–3.5 kW

-

Stage 2: ~5 kW

But the beauty is they don’t run at full blast unless the room needs it.

Tony chooses dual-stage when:

-

The room has major daily swings (sunrise freezing → afternoon roasting)

-

Occupancy varies

-

The building is semi-tight, not fully tight

-

The climate has heavy swings in shoulder seasons

-

The owner wants the most stable comfort

-

Electrical capacity supports it

-

The PTAC is a premium model like the Amana J-Series 15k BTU

Why Dual-Stage is powerful:

-

Smooth temperature control

-

Less cycling

-

Lower energy bills

-

Longer equipment life

-

Best for large rooms where heating load varies

Dual-stage is what Tony calls “comfort insurance.”

🌡️ Why Electric Heat Needs Design — Not Just Installation

Electric heat uses a LOT of power.

More than most homeowners expect.

A 5 kW heater at 230V uses:

A 3.5 kW heater uses:

PTACs themselves often draw 6–8 amps cooling.

This means Tony MUST consider:

-

Circuit size

-

Wire gauge

-

Breaker type

-

Voltage quality

-

Inrush current

The U.S. DOE has reference material on electric resistance heating here:

https://www.energy.gov/energysaver/electric-resistance-heating

Tony never installs a heat kit without checking:

-

the panel

-

the run length

-

the breaker quality

-

the building age

-

the conductor type

-

the outlet conditions

Because electric heat is unforgiving.

🧮 Tony’s Load-Based Heat Kit Sizing Method (Not a Chart!)

Tony sizes heat kits by heating load, not by room size.

This formula gets you close:

Step 1. Calculate heating ΔT (difference between indoor setpoint and outdoor design temp)

Example:

Indoor setpoint: 70°F

Outdoor winter design temp: 20°F

ΔT = 50°F

Step 2. Multiply ΔT by room leakage class

-

Tight room = ×1.0

-

Normal = ×1.3

-

Leaky = ×1.6

Step 3. Multiply by room’s load shape factor

-

One exterior wall = ×1.0

-

Two walls = ×1.3

-

Heavy glass = ×1.5

-

Over garage = ×1.4

Results give Tony the heating severity score:

| Severity Score | Recommended Heat Kit |

|---|---|

| 1–2 | 3.5 kW |

| 2–3.5 | 5 kW |

| 3.5–5 | Dual-Stage |

This is not textbook sizing.

It's real-world Tony sizing.

🧊 Heat Pump Limitations (And When Electric Must Take Over)

Most PTAC heat pumps lose 30–60% of output as outdoor temps fall.

At 35°F, a PTAC heat pump may produce only 40–60% of its rated output.

At 20°F?

It may produce almost no usable heat, forcing electric heat to carry the full load.

ASHRAE’s heat pump performance research backs this behavior:

https://www.ashrae.org/technical-resources/ashrae-handbook

This is why Tony says:

“If you live where it freezes, the heat pump is the face.

The electric heat kit is the muscle.”

🧱 Room Scenarios and Tony’s Heat Kit Choices

Here are Tony's real-life examples:

🛏️ Scenario 1: Standard Hotel Room

-

275 sq ft

-

One exterior wall

-

8 ft ceiling

-

Normal insulation

-

Mild winter climate

Tony picks: 3.5 kW

Enough to carry the load, low electrical strain, smooth heating.

🌇 Scenario 2: West-Facing Apartment Bedroom

-

340 sq ft

-

Big sliding door

-

Mid-rise building

-

Heat pump struggles in mornings

Tony picks: 5 kW

Because morning recovery loads are high.

🧱 Scenario 3: Basement Suite With Two Exterior Walls

-

400 sq ft

-

High humidity

-

Poor insulation

-

Two occupants working from home

Tony picks: 5 kW

Possibly dual-stage depending on infiltration rate.

🏢 Scenario 4: Loft Office With 12 ft Ceilings

-

280 sq ft

-

Metal stud framing

-

Variable occupancy

-

Large windows

Tony picks: Dual-Stage

Two reasons:

-

Big swings

-

High ceiling + metal studs = massive morning load

🛋️ Scenario 5: Living Room With 15k Amana PTAC

-

450 sq ft

-

Two exterior walls

-

High traffic

-

Furniture blocking airflow

-

Tight schedule of heating & cooling switches

Tony picks: Dual-Stage always.

This matches the strength of the 15k compressor and provides the most stable comfort.

🧯 Why Oversizing a Heat Kit Is Almost Impossible

Unlike cooling, you cannot realistically oversize electric heat.

If a room only needs Stage 1, dual-stage units avoid overheating.

Even a 5 kW heater will simply cycle more efficiently in a small room if airflow is correct.

💨 But Undersizing Heat Kits Causes Expensive Problems

Here’s what Tony sees when people choose too-small heat kits:

-

Long run times

-

High electricity bills

-

PTAC overheating

-

Burned-out overload switches

-

Slow recovery

-

Cold complaints

-

Compressor stress

-

Blower motor strain

-

Mold issues from cool, damp interiors

Most heat kit failures come from one thing:

“The installer sized it for the brochure, not the room.”

🛡️ Safety Isn’t Optional With Electric Heat

Tony checks ALL of the following before installing a heat kit:

-

Wire gauge

-

Breaker size

-

GFCI/AFCI requirements

-

Voltage stability

-

Panel load calculation

-

Sleeve airflow path

-

Filter condition

-

Supply/return clearance

The NFPA has strict guidelines on electrical heat safety

🧩 Heat Kit + Sleeve + Room = Full System Design

Tony always treats the heat kit as one part of a 3-component system:

1. The PTAC (cooling/heating engine)

2. The Sleeve (airflow restriction device)

3. The Room (the load boss)

If any of the three are mismatched, system performance plummets.

This is why Tony builds designs around the room, not the equipment spec sheet.

📐 Tony’s Final Sizing Cheat Sheet

| Room Condition | Heat Kit |

|---|---|

| One exterior wall, mild winters | 3.5 kW |

| Two exterior walls | 5 kW |

| High ceilings | 5 kW or Dual |

| Large windows | 5 kW or Dual |

| High humidity | 5 kW |

| Over garage or basement | Dual |

| Daily temp swings | Dual |

| Very tight homes | Dual |

| Older buildings with drafts | 5 kW |

🏁 **Final Word — Electric Heat Is the System

Not the Backup**

If you're sizing PTACs like it’s 1995 — cooling first, heat as an afterthought — you're doing it wrong.

Tony’s system-design truth:

“Cooling is predictable. Heating is where systems fail.

Get the heat kit right, and your whole PTAC runs right.”

When you choose the right heat kit:

-

Rooms warm faster

-

Energy bills stabilize

-

PTACs last longer

-

Compressors stay protected

-

Customers stop complaining

-

Comfort stays consistent year-round

When you choose the wrong one…

You’ll wish you had listened to Tony.

Buy this on Amazon at: https://amzn.to/47cH9ut

In the next topic we will know mmore about: A PTAC Can Only Breathe Through the Sleeve — So Don’t Cheap Out