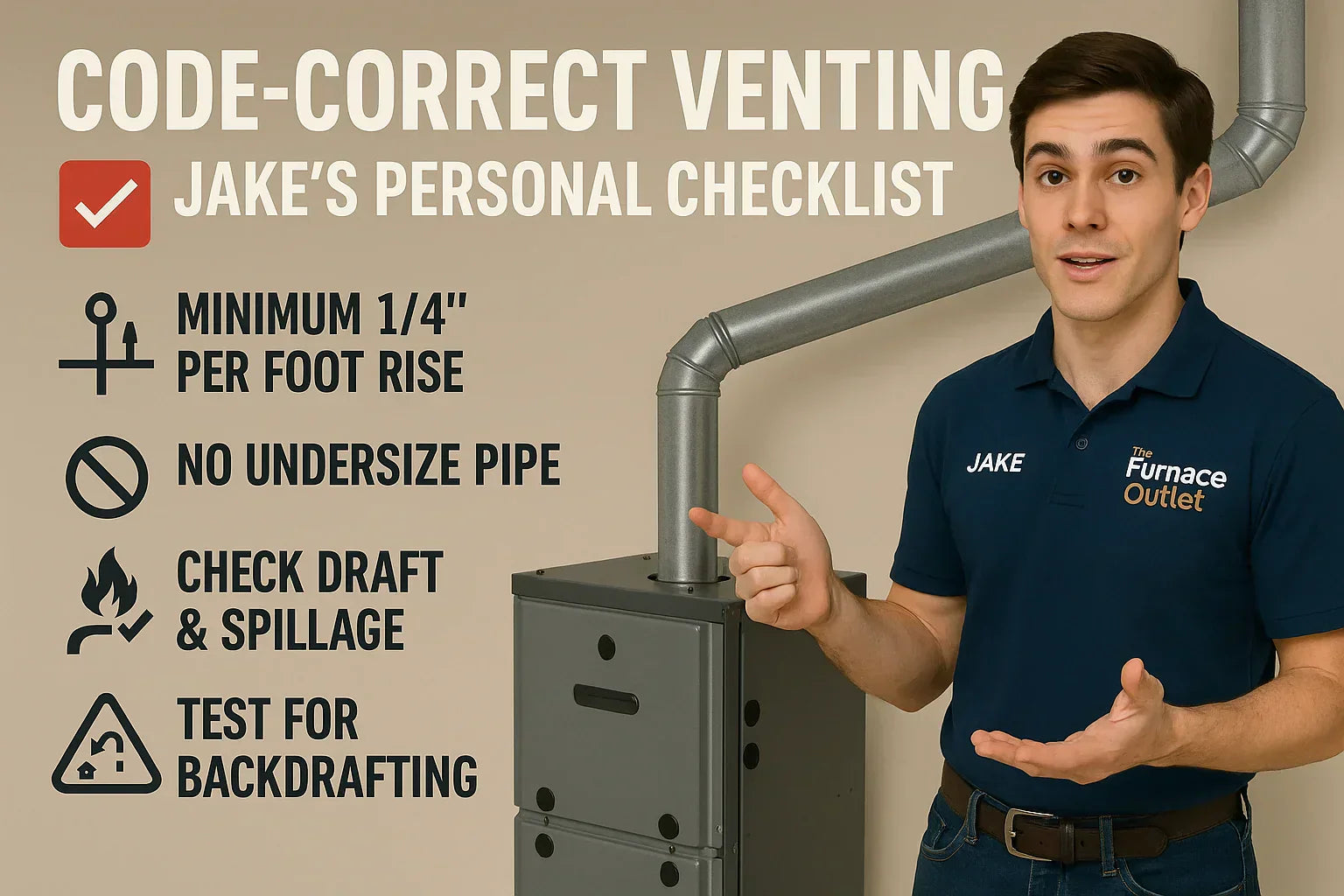

Jake’s proven method for ensuring every 80% furnace vents safely, drafts correctly, and never dumps combustion gases back into the home.

🧭 1. Why 80% Furnaces Fail More Often at the Vent, Not the Burner

Icon: 🧭

Most installers think an 80% furnace is “simple.” No PVC. No condensate trap. No fancy ECM draft inducer. Just metal pipe and a basic rise.

80,000 BTU 80% AFUE Upflow/Horizontal Single Stage Goodman Gas Furnace - GR9S800803BN

Jake shakes his head every time:

“80% furnaces are simple—until the venting is wrong. Then you get rollout, backdrafting, soot, and ruined heat exchangers.”

80% furnaces rely entirely on:

-

Natural draft airflow

-

Proper rise angle

-

Correct pipe sizing

-

Adequate combustion air

-

Chimney reliability

If ANY of the above is off even slightly:

-

Flue gases spill

-

Flame pulls sideways

-

Heat exchanger overheats

-

CO levels spike

-

Draft hood spills

-

Upstairs smells like hot metal

-

Rollout switch trips

Jake built his Code-Correct Venting Checklist because, in his words:

“A furnace doesn’t know the code. It only knows physics.”

And physics ALWAYS wins.

Jake’s Code-Correct Venting Checklist (The 11 Critical Steps)

Each step comes with real-world explanation + Jake’s field logic.

📏 2. Step 1 — Confirm the Vent Rise Angle: Minimum ¼” Per Foot, Jake Aims for 1/2”

Icon: 📏

Code requires:

⬆️ 1/4 inch rise per foot

(Per common mechanical code guidelines)

But Jake installs ½ inch per foot whenever possible.

Why?

Because draft on 80% units is weak compared to modern 90–96% systems.

Draft needs HELP.

Jake’s rule:

“If it barely meets code, it barely drafts.”

Jake’s ideal vent angle:

-

Minimum: ¼” per foot

-

Preferred: ½” per foot

-

Maximum: Enough rise without touching joists or causing uphill dips

What he avoids:

-

Dips

-

Sags

-

Horizontal runs longer than necessary

-

Any section where condensation could collect

Even on a dry-vent system like an 80%, dips kill draft.

🌬️ 3. Step 2 — Size the Vent Pipe Correctly (No Guessing, No Eyeballing)

Icon: 🌬️

Jake never sizes a vent based on “what was there before.”

Old systems used:

-

Oversized vents

-

Metal flues meant for 100k–120k BTU

-

Masonry chimneys sized for multiple appliances

When you attach an 80% furnace to an oversized flue → backdrafting begins.

Jake’s rule:

✔️ Match the pipe to BTU

For an 80,000 BTU furnace like the GR9S800803BN, Jake typically uses:

-

3-inch vent for short runs

-

4-inch vent for longer runs

-

Never bigger unless chimney requires it

Oversized vent = cold flue = NO draft.

🚫 4. Step 3 — NEVER Reduce Vent Diameter

Icon: 🚫

Jake refuses to reduce vent size downstream.

He avoids:

-

4” to 3” reducers

-

6” masonry flues reduced to 4” connector

-

Shared water heater vents where furnace is undersized

Reduction = turbulence = backdraft.

Jake says:

“Reducing a vent is like pinching a straw. It’ll blow back in your face.”

🏚️ 5. Step 4 — Inspect the Chimney (Most Common Backdrafting Cause)

Icon: 🏚️

Older chimneys cause the most problems.

Jake finds:

-

Oversized masonry flues

-

Flues colder than outdoor air

-

Reverse drafting due to cold air falling

-

Bird nests

-

Lack of clay liner

-

Mortar blockages

-

Crumbling interior walls

If the chimney is oversized or cold, he installs:

✔️ Stainless steel chimney liner

Corrects:

-

Draft speed

-

Flue temperature

-

Condensation

-

CO spillage

Jake calls this:

“Putting a warm pipe inside a cold box.”

It works. Every time.

🔥 6. Step 5 — Check the Draft Hood for Spillage

Icon: 🔥

After first fire, Jake places:

-

A lighter flame

-

A smoke pen

-

Or a tissue test

Near the draft hood.

If smoke/tissue falls or lingers → backdraft.

If flame pulls inward → proper draft.

Jake says:

“The draft hood is the furnace’s throat. If it’s coughing, something’s wrong.”

He tests with:

-

Door open

-

Door closed

-

Blower on

-

Blower off

-

Dryer running

-

Exhaust fan running

Why all those?

Because negative pressure from other appliances causes rollout.

🌀 7. Step 6 — Perform the Draft Pressure Test With a Manometer

Icon: 🌀

Jake measures draft in inches WC.

Typical natural draft target:

✔️ -0.01” to -0.04” WC

(depending on code & manufacturer)

Jake’s ideal range:

-0.02 to -0.03" WC

Too weak? Backdraft danger.

Too strong? Flame distortion, noise, and heat exchanger stress.

He tests draft:

-

At the breach

-

Mid-run

-

End of chimney (via port)

Jake NEVER signs off until draft stays steady for 5–7 minutes.

🪟 8. Step 7 — Verify Combustion Air (The Silent Backdraft Killer)

Icon: 🪟

Furnaces need a LOT of air.

For 80k BTUs:

4,000 cubic feet of combustion air

OR a properly sized combustion air duct.

Jake tests by:

-

Opening the closet door

-

Closing the closet door

-

Running a smoke pen

-

Watching flame stability

If flame wobbles → insufficient air → backdraft.

Jake installs:

-

Louvered doors

-

Upper/lower vents

-

Dedicated combustion air piping

He has lost count of how many “bad venting” issues were actually combustion air issues.

🧯 9. Step 8 — Remove All Vent Dips, Sags, and Inverted Joints

Icon: 🧯

Jake inspects the vent like a roof inspector.

What he fixes:

-

Dips

-

Belly sags

-

Inverted elbows

-

Condensation traps

-

Screws protruding inside pipe

-

Sharp turns beyond 90° total equivalent

-

Poor transitions

Dips cause:

-

CO pooling

-

Delayed draft

-

Cold spots

-

Frost formation in chimneys

-

Puffing and rollout

He re-hangs vent sections with:

-

Metal strap

-

Vent support brackets

-

Rigid braces

Jake says:

“The vent should look like a smooth highway ramp, not a pothole street.”

🧱 10. Step 9 — Seal All Vent Connections (But Not the Draft Hood!)

Icon: 🧱

Jake uses:

-

Foil tape

-

High-temp silicone (where code allows)

-

Sheet metal screws

He seals:

-

Elbows

-

Joints

-

Transitions

-

Flue collar connections

He does NOT seal:

-

Draft hood edges

-

Relief openings

-

Relief ports

Sealing a draft hood violates function AND code.

🧰 11. Step 10 — Test Under Full System Load

Icon: 🧰

Jake performs:

✔️ High-heat run for 10 minutes

To ensure draft increases, not decreases.

✔️ Blower-only mode

Checks if static pressure reverses draft.

✔️ Dryer + bathroom fan test

Simulates real-world negative pressure.

If the draft reverses when exhaust fans run → fix the air or venting path.

Jake says:

“Test like a homeowner, not an inspector.”

Inspectors test ideal conditions.

Jake tests normal chaos.

📋 12. Step 11 — Jake’s Final 9-Point Venting Sign-Off Checklist

Icon: 📋

Jake won’t sign his name unless:

-

✔️ Proper rise: ¼–½” per foot

-

✔️ Correct vent diameter

-

✔️ No reductions

-

✔️ No sags or dips

-

✔️ Draft hood pulls consistently

-

✔️ Manometer draft in correct range

-

✔️ No backdrafting under ANY appliance load

-

✔️ Chimney inspected or lined

-

✔️ Combustion air verified

He says:

“If the vent is right, the furnace behaves. If the vent is wrong, the furnace screams for help.”

And he’s right.

📚 13. External Verified Resources (Up to 6)

All safe, reliable, and non-competing.

-

ENERGY.gov — Furnace venting basics

https://www.energy.gov/energysaver/furnaces-and-boilers -

ASHRAE Standards — Ventilation & combustion air requirements

https://www.ashrae.org

🏁 14. Final Word From Jake

Jake teaches every apprentice the same thing:

“Venting is where 80% furnaces live or die.

You don’t install a vent—you design it.”

With Jake’s Code-Correct Venting Checklist:

-

No rollout

-

No spillage

-

No cold flue

-

No CO risk

-

No callbacks

-

No angry inspectors

-

No homeowner complaints

Just a quiet, safe, perfectly drafting 80% furnace—exactly how Jake installs every one.

Buy this on Amazon at: https://amzn.to/3L2nAfF

In the next topic we will know more about: Jake’s Precision Tool Pass: How to Use the Amazon Torch/Detection Kit for Perfect Burn Patterns and Clean Ignition