Key Takeaways

-

Wall Sleeve: Replace or square it to stop drafts, rattles, and leaks.

-

Support: Frame and add lintel to prevent cracks and keep alignment.

-

Power: Use dedicated circuit with correct voltage to protect electronics.

-

Seal & Tilt: Flash opening and tilt outward for rain drainage.

-

Clearances: Allow space for airflow, service, and quieter running.

-

Commission: Check amps, drainage, and refrigerant for pro setup.

Retrofits That Don’t Leak, Trip Breakers, or Rattle

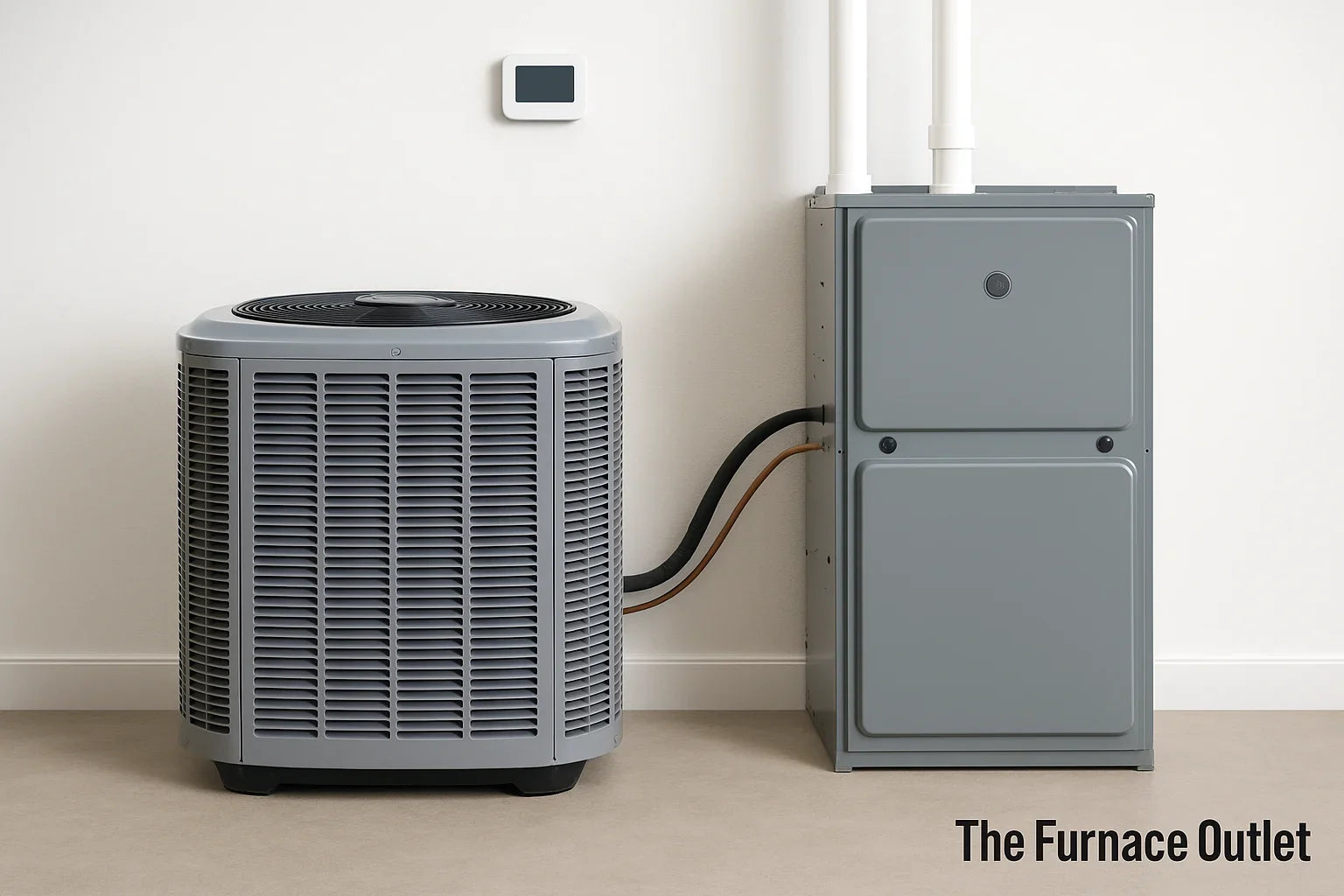

Retrofitting a PTAC into an older building sounds simple—slide it in and plug it in—but most problems start before the unit ever runs. Old sleeves are bent or rusty, walls aren’t square, and wiring can be undersized. That’s how you get rain leaks, buzzing panels, and breakers that trip on hot afternoons. In this guide, I’ll show you how pros retrofit PTACs so they run safely and quietly for years. You’ll learn how to choose or replace the wall sleeve, reinforce the wall, match power correctly, weatherproof the opening, and test the final install. If you want general reading on PTAC basics and care, explore The Furnace Outlet’s HVAC Tips blog for step-by-step articles and visuals, which pair well with this retrofit checklist. (The Furnace Outlet)

The Common Problem in Older Buildings

Here’s the usual story: the old sleeve is out of square, the exterior seal is cracked, and the unit drains backward because the sleeve sits flat or even tilted inward. Inside, the outlet shares a circuit with lights, and the breaker is only 15 amps. Outdoors, bushes block the grille. Each issue seems small, but together they cause water stains, musty odors, high energy bills, and early compressor failures. The fix is not guesswork. Start by deciding whether the sleeve can be reused. If it’s corroded, twisted, or the gaskets are brittle, replace it. Plan for a dedicated circuit sized to the PTAC’s nameplate. Then treat the opening like a window: integrate flashing, sealants, and your weather-resistant barrier (WRB) so wind-driven rain can’t find a path indoors. Finally, protect airflow and maintenance space so the unit can actually breathe and be serviced.

Wall Sleeves: Inspect, Square, Replace, and Seal

The sleeve is the PTAC’s “foundation.” If it’s wrong, the best unit will still underperform. Inspect for rust, dents, stripped threads, and warped flanges. Measure diagonals to check square—if the diagonals don’t match, the sleeve is twisted. When replacing, choose a corrosion-resistant sleeve matched to your brand and grille. Dry-fit in the wall and verify it is level left-to-right and has a slight outward tilt front-to-back. Use closed-cell foam or gasket kits to seal the sleeve perimeter to the wall, but don’t over-compress the foam; that can transmit vibration. After install, confirm the chassis slides in smoothly without forcing. For a deeper dive on sleeves and why alignment matters, see The Furnace Outlet’s wall-sleeve guidance and sealing tips. (The Furnace Outlet)

Related products: Check Hotel Heat & Air Units (PTACs) for compatible sleeves and chassis options that match most retrofit needs.

Structural Support: Framing, Lintels, and Fasteners

A PTAC opening is a real structural change. In masonry, use proper anchors (e.g., Tapcon-style screws) sized for sleeve flanges and any mounting brackets. In framed walls, install solid wood studs around the opening and a lintel/header above the sleeve to carry wall load, especially under windows. Keep fasteners snug, not overtight—warping the sleeve throws off the chassis fit and can buzz. Protect the base pan: never drive screws through the pan or set the unit on fastener heads; punctures cause condensate leaks into the wall. Before closing up, sight along the sleeve to confirm the face is flush with the exterior finish so trim rings seal evenly. Maintain at least 24 inches of clear space in front of the unit indoors so filters and controls are easy to reach later. Good structure = quiet unit, clean drainage, and less call-backs.

Electrical: Dedicated Circuits, Voltage Match, Grounding

Most retrofit headaches are electrical. Modern PTACs commonly need dedicated 15, 20, or 30-amp circuits—no lights, no outlets on that line. Match the nameplate voltage: many residential/light-commercial models are 208/230V; some commercial corridors use 265/277V. Get this wrong and you risk failed boards or nuisance trips. Use the correct plug/receptacle or hardwire kit per the manufacturer. Confirm wire gauge for the run length and breaker size (check local code, e.g., NEC in the U.S.). Bond the equipment ground, and keep each PTAC on its own circuit to isolate faults. If you’re upgrading many rooms, label panel schedules clearly; it saves hours later. For buyers planning a new chassis, browse R-32 PTAC units and PTAC heat pump models to match capacity and voltage from the start.

Weatherproofing: Sealants, Flashing Tape, and Sleeve Tilt

Think like rain. First, integrate the sleeve with the WRB. Apply flashing tape to the top and sides so water shingled from above moves around the opening, not behind it. Add a lower “pan” or flashing strip as a gutter. Run a continuous bead of exterior-grade silicone at the sleeve flange, but don’t block weep paths. Most important, tilt the sleeve slightly outward—about the thickness of a few quarters—so rain and condensate drain outside, not into the wall. Keep the sleeve level left-to-right to prevent side pooling. After caulking, water-test with a garden sprayer, then re-seal any pinholes you find. The Furnace Outlet’s sleeve-sealing guide shows tilt, flashing, and sealing order at a glance—use it as a quick check before closing the wall. (The Furnace Outlet)

Tip: Stock up on accessories & sealants ahead of time.

Clearances and Placement: Airflow In, Water Out

PTACs pull and push a lot of air. Outside, keep at least a couple of feet clear in front of the grille—no shrubs, fences, or stacked furniture blocking intake and exhaust. Avoid alcoves that trap hot exhaust; it recirculates and cooks the unit. Inside, maintain the manufacturer’s side and top clearances for curtains, beds, and furniture. Don’t run drapes into the discharge path; it causes short-cycling and noisy airflow. Keep units spaced apart on long walls so service doors can open fully. If your facade has deep rain screens or louvers, verify the front grille style is compatible so airflow isn’t starved. To compare chassis and grille options that handle tricky placements, see Through-the-Wall Heat Pumps and Hotel Heat & Air Units collections.

Commissioning & Testing: A Simple, Pro-Level Checklist

Before you call it done, commission the system. Measure supply/return temperature split in cooling (typically 16–22°F on a healthy system in normal indoor humidity). Check amperage draw against the nameplate at high fan and full cool/heat. Confirm the condensate drains outside—pour a cup of water into the pan and watch it exit. Test both heating modes (electric strip or heat pump) if present. Verify the control board settings and lockouts, and test the wall thermostat, if used. Listen for vibration—often cured by re-seating the chassis and tightening trim evenly. Finally, inspect seals inside and out for light gaps. For a friendly walkthrough of install steps and what to expect on day one, see PTAC Installation 101 on our blog. (The Furnace Outlet)

Need a double-check? Use our Quote by Photo service to get expert eyes on your setup.

Efficiency & Sizing: Pick the Right PTAC for the Room

Right size = right comfort. Oversized PTACs short-cycle and leave rooms humid; undersized units run loud and never catch up. Use room area, window size, sun exposure, and insulation level to select capacity. A practical starting point is The Furnace Outlet’s PTAC sizing chart, which turns square footage and conditions into BTU options you can trust. (The Furnace Outlet) In mild U.S. climates, heat-pump PTACs cut winter electricity use versus electric-heat models; in very cold climates, electric heat may be simpler as backup. If you’re refreshing many rooms, standardizing on R-32 PTACs helps future-proof refrigerant compliance.

FAQs

-

Can I reuse an old wall sleeve? Yes, if it’s square, not rusted, and seals tight. If in doubt, replace—it’s cheaper than fixing leaks later.

-

How much should I tilt the sleeve? Keep it level side-to-side, but tilt slightly outward so water drains outside (a few degrees is enough). (The Furnace Outlet)

-

Do PTACs need their own breaker? Best practice is a dedicated 15/20/30-amp circuit matched to the unit’s nameplate and local code.

-

208/230V vs 265/277V—how do I choose? Match the building’s power. Many hotels use 265/277V in corridors; apartments are often 208/230V.

-

What clearances should I plan for? Keep about 24" indoors for service and a couple of feet outside for free airflow; check your model’s manual.

-

Heat pump or electric heat? Heat pumps save energy in mild climates; electric heat is simple and reliable in very cold snaps.

-

Who can check my retrofit plan? Share photos and specs via The Furnace Outlet’s Quote by Photo page for guidance.