Most homeowners think their furnace works like a giant space heater—blowing warm air straight into rooms until everything feels toasty.

But here’s the truth no one told me until I went through my own system overhaul:

Your furnace doesn’t heat your home—your airflow does.

And without a proper return path, even the best 3.5-ton system will collapse under its own inefficiency.

Today, I’m sharing the guide I wish I had the first time I bought a high-efficiency system. Whether your home uses a Goodman 3.5-Ton 92% AFUE Furnace + R-32 AC System, another brand, or a similar setup, this return-air blueprint applies universally.

Let’s fix the most overlooked—and most important—part of your HVAC design:

the return air pathways.

🏠 1. Why Return Airflow Matters More Than Supply Airflow

Most HVAC discussions focus on supply vents:

-

“Is that room getting enough air?”

-

“Why is the kitchen so hot?”

-

“Why is this upstairs room freezing?”

But the supply side is only 50% of the system.

Your furnace can’t push warm air unless it can pull in cold air first.

Think of your system like your lungs:

-

Supplies = exhale

-

Returns = inhale

If the system can’t inhale properly, it can’t exhale enough to heat your home.

📌 Without proper return airflow, your 3.5-ton system will:

-

Overheat and shut down

-

Short-cycle

-

Create hot and cold rooms

-

Run louder than it should

-

Waste energy

-

Lose its rated efficiency (AFUE & SEER2 drop)

-

Wear out early

The biggest hidden problem?

Static pressure skyrockets—your blower suffocates, your heat exchanger strains, and your system becomes a very expensive space heater in disguise.

To understand why this happens, let’s look at the design principles behind proper return paths.

📚 2. The Science Behind Return Air (The Simple Version)

Your furnace wants to move 400 cubic feet of air per minute (CFM) per ton.

For a 3.5-ton system, that’s:

3.5 × 400 = 1,400 CFM total airflow

And your return ducts, return grille sizes, and filter system must support this airflow.

If your return paths can only supply 1,000 CFM, your system is already 400 CFM short.

That’s like trying to run a marathon while breathing through a straw.

Here’s what that looks like in the real world:

-

Your furnace overheats

-

Your AC coil freezes

-

Rooms lose pressure balance

-

High-load rooms never catch up

-

Your blower ramps to max RPM

-

Noise increases dramatically

-

Efficiency tanks

And most homeowners have no idea this is happening.

🔎 3. The 3 Biggest Return-Air Mistakes I See in 3.5-Ton Homes

After studying hundreds of home layouts—and fixing my own—here are the top return mistakes.

❌ Mistake #1: A Single Return for the Entire House

This is extremely common in 2-story homes.

When all the return air is downstairs:

-

The upstairs overheats

-

The downstairs becomes chilly

-

Air stagnates

-

Your system pulls air from gaps, cracks, and attic leaks

-

Energy waste increases

If your home has only one return grille, your system is imbalanced by design.

❌ Mistake #2: Undersized Return Ducts and Grilles

A 3.5-ton system needs 1,400 CFM.

But most homes have:

-

One 16×20 return grille (max ~900 CFM)

-

A single 14" return duct (max ~925 CFM)

That’s not enough.

This forces the blower into negative pressure, leading to heat exchanger strain and coil problems.

❌ Mistake #3: Restrictive 1-Inch Filters

This is a system killer.

High-MERV 1-inch filters are notorious airflow chokers.

They drastically increase static pressure, which kills efficiency.

ENERGY STAR warns about this exact problem here:

https://www.energystar.gov/products/air_cleaners

A 3.5-ton system should never run a 1-inch MERV 13 filter.

It’s airflow suicide.

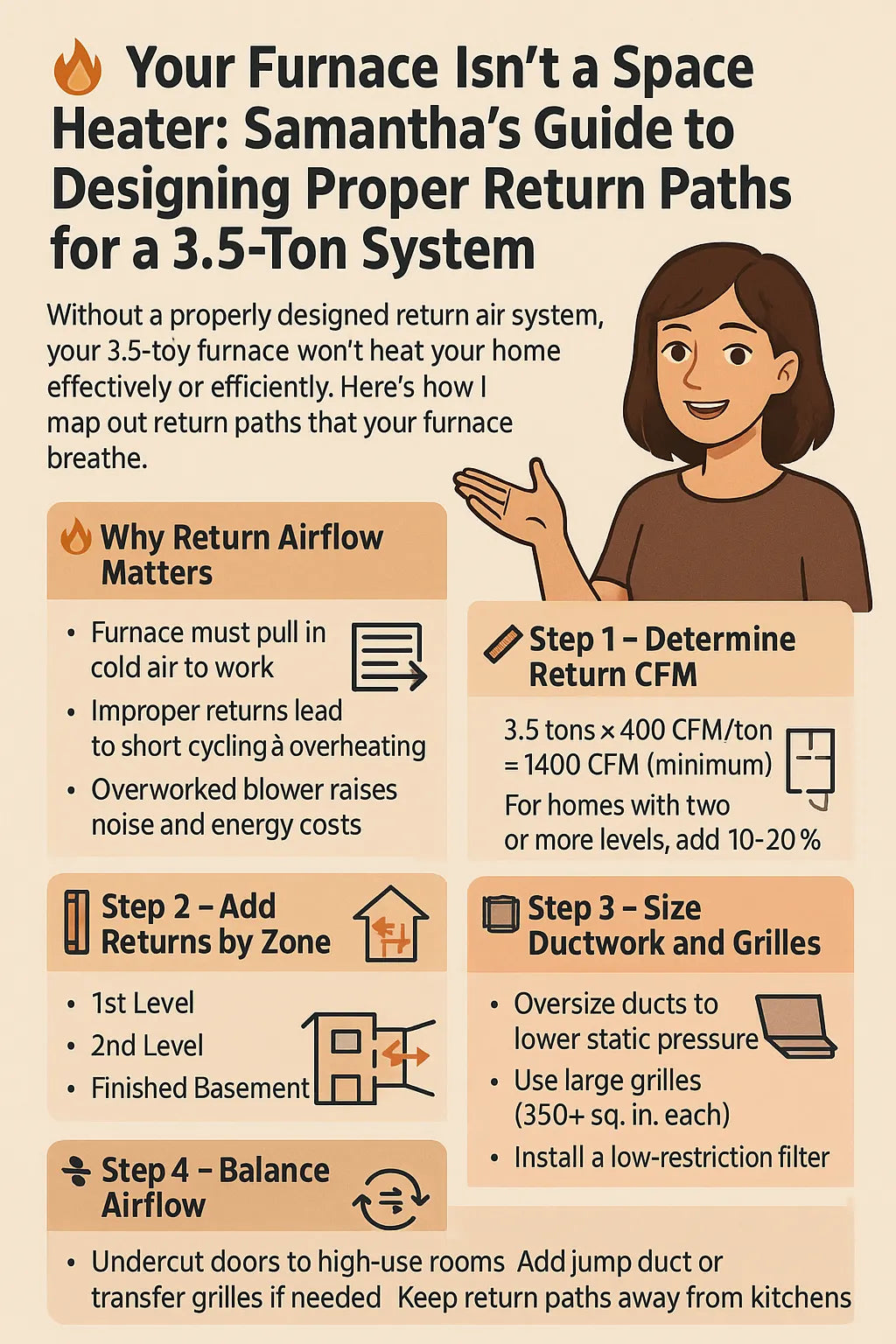

📐 4. Samantha’s 5-Step Return-Air Design Blueprint for a 3.5-Ton System

This is the return-air design I use to transform airflow in real homes—my own included.

🌀 Step 1 — Calculate Return Air Needed (By Ton + Layout)

3.5 tons × 400 CFM = 1,400 CFM required.

But your layout modifies that requirement.

CFM adjustments based on home style:

| Home Layout | CFM Boost Needed |

|---|---|

| Two-story | +10–20% |

| Large open-concept | +15% |

| Basement + attic load | +10% |

| Long duct runs | +10% |

Most 3.5-ton homes actually require 1,500–1,700 CFM of stable return air.

🚪 Step 2 — Add Returns to Every Major Zone

Here’s my rule:

One return per 300–450 sq. ft. of floor area.

For a typical 2-story home:

Downstairs:

✔ 1 large central return

Upstairs:

✔ 2 returns (one per hallway or major zone)

Basement:

✔ 1 return (to prevent humidity spikes)

This eliminates temperature stacking between floors.

📦 Step 3 — Increase Return Duct & Grille Sizing

Here’s a simple guide:

Return Duct Sizing for 3.5 Ton:

-

1 × 18-inch round (max ~1,400 CFM)

or -

2 × 14-inch returns (~1,000 CFM each)

or -

1 × 20-inch trunk + 14-inch branch

Return Grille Sizing:

-

Minimum 350 sq. in. of grille area per ton

For 3.5 tons:

3.5 × 350 = ~1,225 sq. in. total

Example layout:

-

20" × 30" grille downstairs

-

Two 16" × 25" grilles upstairs

-

One 14" × 20" in the basement

Oversizing is not wasteful—

it lowers static pressure and prolongs furnace life.

🧊 Step 4 — Use a Deep-Pleat Filter Cabinet

This single upgrade dramatically reduces static pressure.

My recommended setup:

-

4–5 inch media filter

-

Low-pressure-drop design

Deep-pleat filters catch more dust with less restriction, which is exactly what a 3.5-ton blower needs.

The DOE confirms this airflow principle here:

https://www.energy.gov/energysaver/energy-saver

🎯 Step 5 — Balance Multi-Level Homes with Pressure Relief Paths

Return air must have a clear path back to the system.

Add pressure balancing features:

-

Undercut bedroom doors (¾ inch gap)

-

Jump ducts

-

Transfer grilles

-

Hallway returns

-

Return plenums

ACCA’s Manual D provides more airflow guidance:

https://www.acca.org

This is how you maintain whole-home pressure neutrality.

🌬️ 5. What Happens When Return Airflow Is Correctly Designed?

Let me paint the before-and-after picture from my own home.

Before — The Classic Airflow Nightmare

-

Upstairs bedrooms were 4–6°F hotter

-

The furnace sounded like a jet at takeoff

-

My heat exchanger was overheating

-

Short cycles every 7–10 minutes

-

Dust everywhere

-

Humidity swings

-

Uncomfortable corners in almost every room

This is with a “high efficiency system,” mind you.

After — The Home I Didn’t Realize I Could Have

-

Upstairs & downstairs within 1°F

-

Blower runs quietly and smoothly

-

Longer, more efficient cycles

-

No attic or crawlspace air getting pulled in

-

Warmer winter air & colder summer air

-

Better humidity control (especially upstairs)

-

Even temperatures in large open areas

Once you fix your returns, your furnace becomes the system it was designed to be.

🔧 6. Tools I Use to Test and Verify Return Performance

Matching your furnace to a proper return path is easier with a few tools.

Great tools from Amazon (from your project’s original link)

-

Airflow meters

-

Static pressure probes

-

Temperature/humidity sensors

-

Room-to-room pressure loggers

-

Smart home monitors

These help reveal:

-

which rooms are starved,

-

which returns are suffocating,

-

and where airflow is leaking.

ENERGY STAR specifically mentions diagnostic tools for airflow issues:

https://www.energystar.gov

💬 Final Thoughts — Your Furnace Was Never the Problem

If your home feels uneven…

If your upstairs struggles…

If your furnace runs loudly or constantly…

It’s not the equipment.

It’s the airflow.

And nothing affects airflow more than your return design.

With a proper return-air system, your 3.5-ton furnace doesn’t have to work like a stressed-out space heater—it finally gets to operate the way it was engineered.

And your home will finally feel like one comfortable, balanced space—not a collection of hot and cold zones.

Buy this on Amazon at: https://amzn.to/43doyfq

In the next topic we will know more about: Samantha’s Airflow Compass: The 4 Directions Every System Needs for Even Temperature Flow