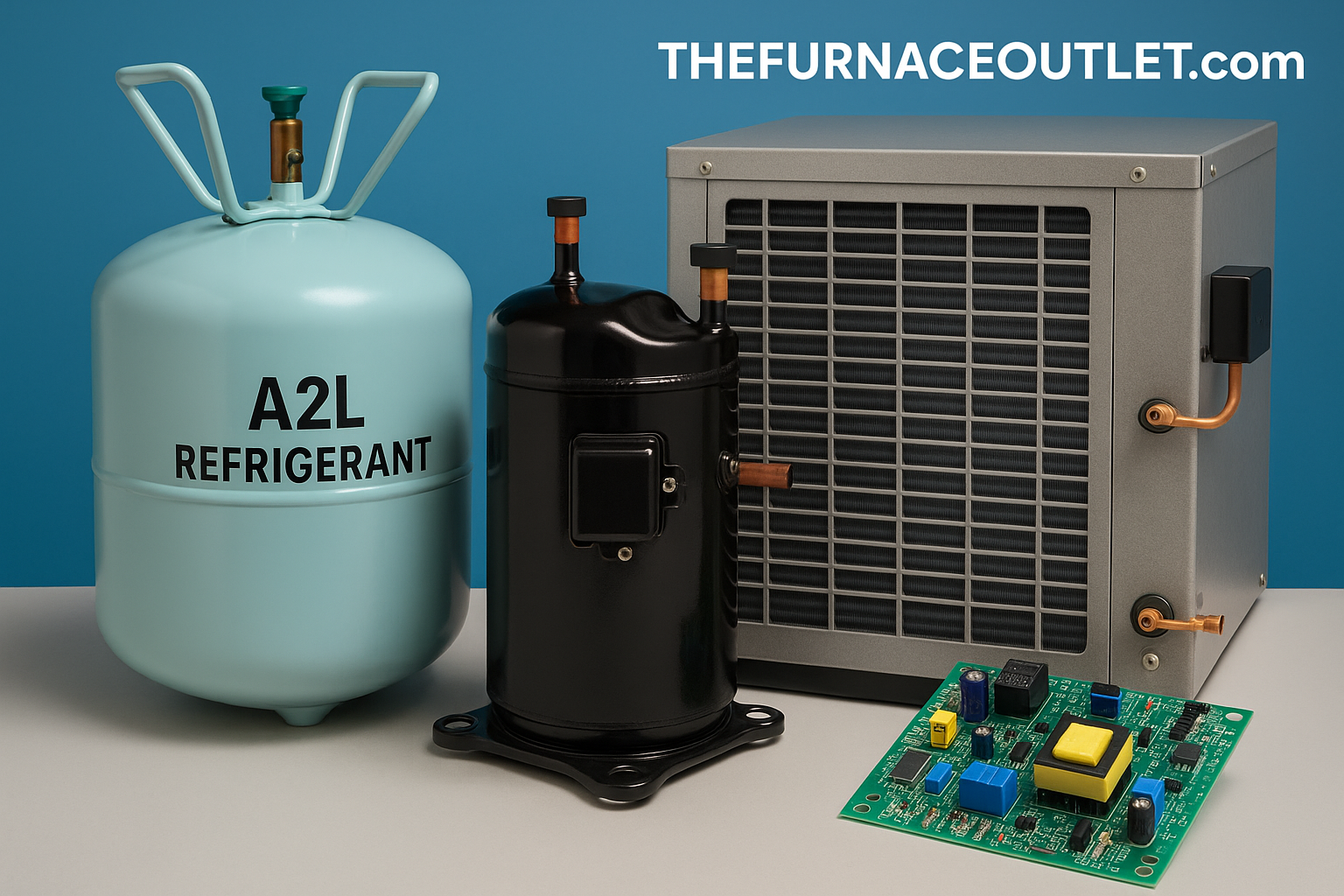

The shift toward A2L refrigerants represents more than just a switch in chemical formulas—it’s a rethinking of how HVAC systems are built and how safe they are. These mildly flammable refrigerants offer lower global warming potential (GWP) than traditional options, helping HVAC systems meet environmental mandates. But their properties also demand big changes in how we design and select electrical components, from compressors to control boards.

Explore R32 dual-fuel packaged units designed for balanced performance and future-ready compliance.

Getting to Know A2L: What Makes Them Different?

A2L refrigerants are classified as low-toxicity, low-flammability compounds with low burning velocity. They include next-gen HFOs and lower-impact HFCs, bridging the gap between high-efficiency performance and safer handling. Their adoption is surging across both residential and commercial applications.

Before choosing your electrical layout, it helps to select the right refrigerant upfront—R454B vs. R32 outlines the performance and safety trade-offs between today’s leading A2L options.

But these refrigerants aren’t plug-and-play replacements. They behave differently—operating at unique pressures and temperatures—and come with strict fire safety considerations. This means every wire, fan, and circuit board must be evaluated for compatibility, reliability, and ignition resistance.

R32-compatible packaged air conditioners are built with compliance and safety in mind.

The Regulatory Pressure Behind the Push

Regulations like the EU F-Gas Regulation, the Kigali Amendment, and the U.S. EPA’s SNAP program are accelerating the shift to A2L refrigerants. These policies push manufacturers toward lower-GWP options while imposing stricter safety standards.

That means HVAC engineers must ensure systems are not just high-performing but also meet new codes around ventilation, leak detection, and fire risk. Designing for A2L Success breaks down how smart design choices help future-proof your system against regulatory demands.

What Electrical Components Must Now Deliver

Electrical systems in HVAC setups powered by A2Ls must rise to the challenge of safety and performance. Compressors must resist spark risks and support different thermodynamic loads. Fans, relays, sensors, and wiring need to withstand exposure to mildly flammable gases while maintaining performance.

A good starting point is ensuring your compressor is up to the task—Is Your Compressor Ready for A2L Refrigerants? offers a practical checklist for evaluating compatibility and safety.

Control boards must now include:

-

Advanced leak detection algorithms

-

Emergency shutoff systems

-

Data logging for compliance reporting

To support those upgrades, HVAC systems also need accurate sensing and smart tech. Stop Leaks Before They Start explains how modern detection systems help keep A2L systems safe and code-compliant.

And all components must be tested to standards like UL, IEC, and ASHRAE to guarantee safety.

Design Priorities: Building A2L-Ready Components

-

Material Compatibility: Components must use materials that won’t degrade or react with A2L refrigerants.

-

Ignition Prevention: Designs need to avoid spark generation. This means spark-proof motors, sealed housings, and upgraded insulation.

-

Thermal Tolerance: Parts must operate reliably across A2L’s unique pressure and temperature ranges.

-

Enhanced Monitoring: Sensors and controllers must actively regulate refrigerant levels, airflow, and system pressures to prevent unsafe conditions.

Browse sensor-ready ductless mini-splits ideal for smart control and safe A2L integration in smaller spaces.

Selecting Safe, Compliant Components

Choosing the right electrical components for A2L systems requires checking:

-

Material resistance to refrigerant exposure

-

Spark safety ratings (intrinsically safe or sealed)

-

Certification under ASHRAE 15, UL 60335-2-40, IEC 60079, etc.

You also need to ensure firmware and software can accommodate A2L-specific control logic. That means precise measurement, early warning systems, and integration with leak detection protocols.

R32 AC and air handler systems come pre-configured for smart control and secure A2L performance.

Key Standards That Guide A2L System Design

-

ASHRAE 15: Lays out refrigeration system safety requirements including for A2Ls

-

ASHRAE 34: Refrigerant classification system based on toxicity and flammability

-

UL 60335-2-40: Electrical safety requirements for HVAC equipment using flammable refrigerants

-

IEC 60079: Safety requirements for explosive atmospheres (applies to electrical equipment)

Meeting these standards isn’t optional—it’s essential to pass inspections, meet codes, and keep people safe.

Lessons from the Field: Case Studies

-

Europe, Office Retrofit: Replaced R410A with A2L refrigerant, upgraded all compressors and sensors. Integrated active ventilation and automated shutoff systems. Result: 30% GWP reduction with no performance loss.

-

Japan, New Residential Build: Designed A2L system from the ground up. Used sealed, spark-resistant electronics, IoT monitoring, and smart control systems. Result: exceeded local efficiency and safety standards.

Where the Industry Is Headed

Expect to see:

-

More integration with IoT for real-time refrigerant monitoring

-

New non-sparking motor and fan designs

-

Advanced sensor calibration tools

-

Software updates for smart diagnostics and remote safety alerts

As A2Ls become standard, HVAC systems must be smarter, safer, and greener.

Designing with Safety and Sustainability in Mind

The HVAC industry is in a redesign moment. A2L refrigerants offer enormous environmental potential, but only if systems are built to handle their unique characteristics.

That means rethinking every electrical component—from wire insulation to control logic—to prevent ignition, improve diagnostics, and ensure regulatory compliance. By embracing these changes, manufacturers and engineers aren’t just meeting new rules—they’re leading the next wave of HVAC innovation.

Ready to build safer, smarter A2L HVAC systems?

Start with UL-certified, R32-compatible HVAC systems from The Furnace Outlet—engineered for next-gen safety, performance, and compliance.