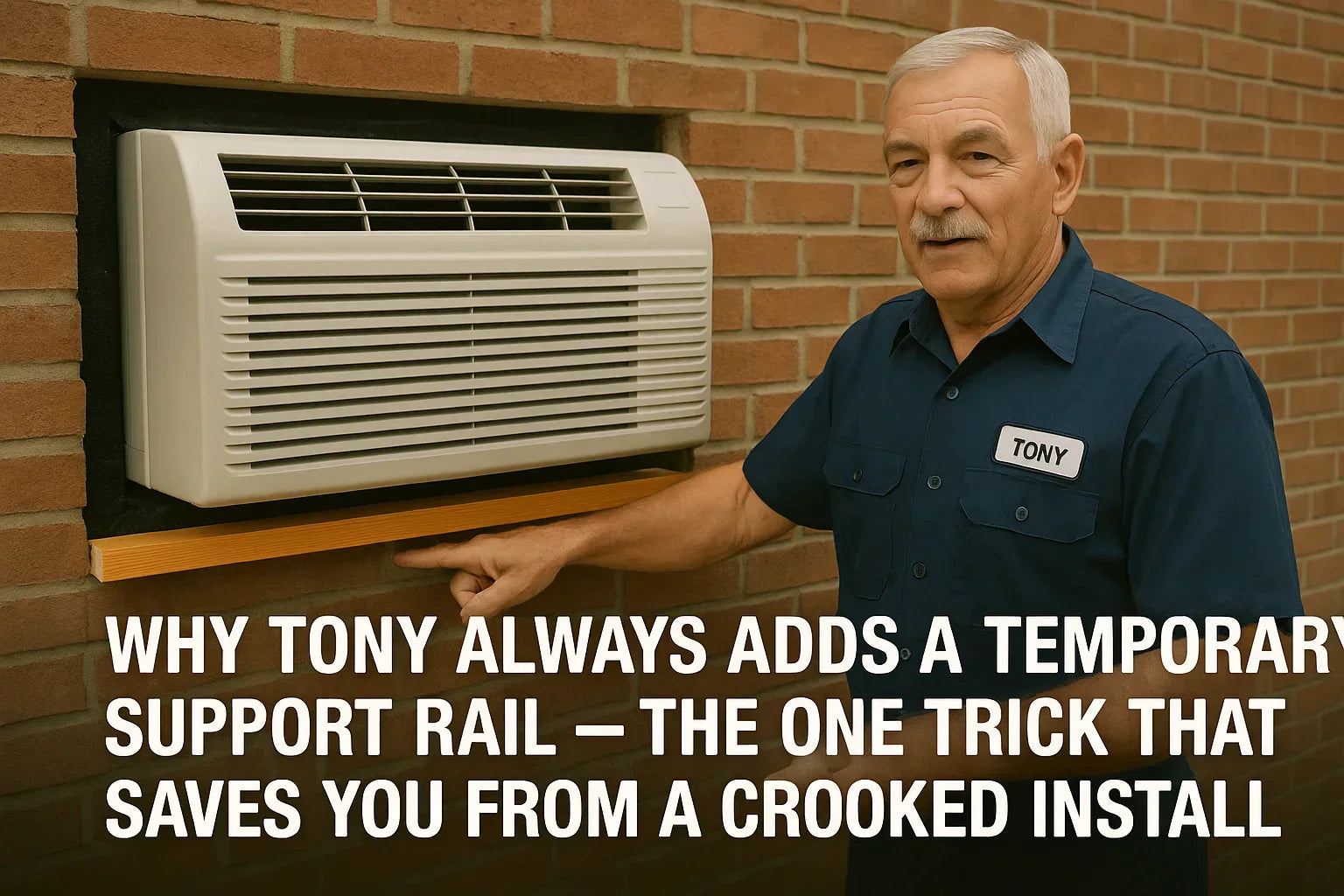

By Tony Marino — “A wall sleeve only goes in straight if you force it to.”

🧱 1. The Ugly Truth: Most Crooked PTAC Installs Start Before the Sleeve Even Goes In

If you’ve ever walked into a hotel room, apartment, or senior living unit and seen a PTAC that looks like it’s leaning to the left, sagging in the middle, or dipping toward the interior…

…it didn’t “settle.”

It didn’t “get bumped.”

It didn’t “warp with age.”

Nope.

It was installed crooked on DAY ONE, and the installer simply didn’t give the sleeve the structural support it needed when sliding it into the wall.

The biggest culprit?

The sleeve is unsupported during installation — and gravity decides the final pitch, not the installer.

That’s why Tony never installs a sleeve without using his secret weapon:

The Temporary Support Rail.

A simple, removable stabilization bar that forces a perfect pitch, perfect squareness, and perfect alignment until the sleeve is secured permanently.

Let’s break down why this is one of the smartest installation tricks you’ll ever learn.

Amana Distinctions Model 12,000 BTU PTAC Unit with 3.5 kW Electric Heat

🔧 2. What the Support Rail Actually Is (and Why Installers Skip It)

A temporary support rail is:

-

A straight, rigid piece of wood or metal

-

Mounted horizontally under the bottom flange of the sleeve

-

Set to the exact pitch needed

-

Removed after foam, anchors, and shims set

It acts like a third hand, holding:

-

Height

-

Pitch

-

Centerline

-

Depth

-

Square

-

Level

All while you:

-

Adjust

-

Foam

-

Screw

-

Square

-

Reinforce

-

Re-check

-

Mount the exterior grille

Most installers skip it because:

-

They think the sleeve “will hold itself.”

-

They’re in a rush.

-

They trust the opening more than they should.

-

They’ve never been taught otherwise.

-

They’ve never gone back to see how crooked their installs became after 12 months.

Tony HAS seen it — thousands of times.

And he refuses to let the sleeve "decide" where it sits.

📐 3. Why Sleeves Go Crooked (Even When You Think They’re Straight)

A PTAC sleeve can be off by:

-

1/8 inch left

-

1/4 inch right

-

3/16 inch downward

-

Slight twist

-

Bowed top plate

-

Rear flange shift

And you won’t notice it until:

-

The chassis vibrates

-

The grille whistles

-

Condensate drains wrong

-

The blower wheel rubs

-

The compressor resonates

-

Hot/cold discharge aims incorrectly

-

Gaps show up around interior trim

Why does misalignment happen?

Because even a perfect hole has:

-

Uneven framing pressure

-

Hidden crown in studs

-

Slight twist in sheathing

-

Soft drywall edges

-

High spot on the sill

-

Low spot on the exterior brick

And worst of all…

Foam expansion will push the sleeve exactly the wrong way unless the rail keeps it locked.

🛠️ 4. Tony’s Golden Rule: “If You Don’t Support the Sleeve, the Wall Will Move It for You.”

A temporary support rail keeps the sleeve from:

✔ Sagging

Sleeves sag 1/16–1/4 inch while you’re not looking.

✔ Rolling forward

A small roll = noisy airflow forever.

✔ Twisting

Even 1° of twist changes grille pressure enough to whistle.

✔ Sliding inward

Foam can push it several millimeters inward before setting.

✔ Sliding outward

Gravity and pitch can drag it out slightly.

✔ Losing pitch

Any pitch loss = interior condensate leaks.

✔ Losing squareness

This causes blower vibration, airflow turbulence, and grille misfit.

The rail stops all of this.

🧰 5. What Happens When You Don’t Use a Support Rail (Real Jobsite Failures)

Here are actual failures Tony has fixed, all caused by unsupported sleeves:

❌ 1. Backward pitch → condensate leaking inside

90% of “PTAC leak” calls are sleeve pitch issues — not unit defects.

❌ 2. Sleeve compression against drywall → vibration noise

Drywall edges flex inward and squeeze the sleeve.

❌ 3. Crooked grill alignment → back-pressure doubling noise

The grille must sit flush or the airflow turns chaotic.

❌ 4. Negative pressure sucking outdoor air through gaps

Even small misalignments create drafts.

❌ 5. Compressor resonance from torsion

A twisted sleeve amplifies vibration into the wall.

❌ 6. Sleeve bow → chassis rails out of alignment

This causes blower wheel rubbing.

❌ 7. Exterior grille rattle

If the sleeve isn’t perfectly perpendicular, grille fasteners never seat right.

❌ 8. Chassis drag

If the sleeve is crooked, the PTAC won’t even slide in smoothly.

Tony has seen everything from warped casings to mold growth because a sleeve wasn’t supported for 10 minutes during install.

🧲 6. The Temporary Support Rail: Simple, Cheap, and Borderline Genius

Here’s what Tony uses:

Option A — 1×2 hardwood strip

Cheap, stiff, doesn’t flex.

Option B — Aluminum L-channel

Perfect straightness, reusable, professional-grade.

Option C — Adjustable steel support bar

Best for uneven masonry or brick.

He pre-cuts rails in common PTAC widths (42" being the standard).

The rail attaches with:

-

Screws into temporary furring strips

-

A clamp system

-

Shims under both ends

-

A laser leveling line

Once the sleeve is installed, shimmed, foamed, squared, anchored, and double-checked, the rail is removed.

📏 7. Tony’s Exact Installation Procedure Using the Rail

This is the real workflow Tony uses.

🛠️ Step 1 — He measures and snaps a laser line

This line represents:

-

True level

-

Correct height

-

Pitch reference

He sets pitch to:

¼ inch downward from inside to outside.

🧱 Step 2 — Install the temporary support rail

Rail is mounted to the snap-line, not the wall studs.

This ensures:

-

True level

-

True squareness

-

Centerline consistency

📦 Step 3 — Dry-fit the sleeve onto the rail

The sleeve should:

-

Sit flat

-

Not rock

-

Not twist

-

Not bow

-

Not slide

If it slides, he uses light clamps or tape to hold it.

🔩 Step 4 — Shim for pitch and squareness

Shims go:

-

Left corner

-

Right corner

-

Center rear

-

Bottom of flange

He aligns until:

-

Both diagonals match

-

Interior reveals are even

-

Sleeve rails are parallel

-

Exterior flange sits flush

🧯 Step 5 — Anchor the sleeve

Anchors go into:

-

Structural framing

-

Masonry areas

-

Reinforced interior panels

Never into weak drywall.

🧽 Step 6 — Foam seal (low expansion only)

This is where most sleeves move — UNLESS they have support.

Foam expands 3–5× its size.

Without the rail:

-

Sleeve bends inward

-

Pitch changes

-

Squareness collapses

The rail keeps everything locked.

🧰 Step 7 — Re-check pitch after foam cures

If it’s wrong?

The rail stays until adjustments are done.

Tony does NOT let foam dictate the geometry.

🪛 Step 8 — Remove the rail & finish trim

After the structure is solid, the rail pops off and Tony installs:

-

Interior trim

-

Exterior grille

-

Chassis

-

Weatherseal

DONE.

🔍 8. Why This Trick Works (The Physics Behind It)

The sleeve is a giant thin metal box.

It doesn’t:

-

Resist torque

-

Hold shape during pressure

-

Stay square when pushed

-

Stay level under load

-

Support itself during install

The rail acts as:

-

A structural reference point

-

A pitch retention device

-

A leveling guide

-

A torsion breaker

-

A sag absorber

-

A twist eliminator

It is the single easiest way to force the sleeve to install exactly the way you want it.

📉 9. Installation Failures Caused by NOT Using a Rail (with Fix Costs)

| Problem | Cause | Fix Cost |

|---|---|---|

| Condensate dripping inside | backward pitch | $200–$800 |

| Whistling grille | sleeve twist | $150–$400 |

| Noisy blower | chassis misalignment | $250–$900 |

| Vibration in wall | sleeve bow | $300–$1000 |

| Mold in wall cavity | moisture pooling | $1000–$5000 |

| Exterior grille falling | off-level flange | $90–$350 |

| Compressor resonance | sleeve torsion | $350–$1200 |

These failures START at installation, but they’re only noticed months later.

🔎 10. Tony’s 30-Second “Did You Do It Right?” Rail Check

Stand in front of the sleeve.

Ask yourself:

✔ Does the chassis slide in smoothly with one hand?

If no → sleeve is crooked.

✔ Are the interior reveals perfectly parallel?

If no → sleeve is twisted.

✔ Does the bubble or laser stay even across the entire width?

If no → sleeve is bowed.

✔ Does the drain flow outward within 1–2 minutes?

If no → pitch is wrong.

✔ Does the exterior grille seat perfectly flush?

If no → flange is not square.

If any answer is WRONG?

You didn’t use the rail correctly — or at all.

📚 11. External Verified Sources Supporting Leveling, Pitch, and Sleeve Stability

Here are reliable resources that align with best practices mentioned in this guide:

-

Energy.gov – Air Sealing Guidelines

https://www.energy.gov/energysaver/air-sealing-your-home -

OSHA – Construction Saw Safety (for proper wall cuts)

https://www.osha.gov -

International Building Code (Wall Framing Requirements)

https://codes.iccsafe.org/ -

UL Guidelines for Electric Heat Components

https://ul.com/ -

ASHRAE Handbook – HVAC Fundamentals (Airflow & Pressure)

https://www.ashrae.org/technical-resources/ashrae-handbook

Equipment only performs correctly when the mechanical support structure is perfectly aligned.

🏁 Final Word From Tony

If you want a PTAC to look right, sound right, drain right, and last 10–20 years, there’s ONE rule you must follow:

“Support the sleeve — or the wall will ruin your install.”

Installers who skip the support rail trust:

-

Gravity

-

Foam

-

Framing

-

Drywall

-

Luck

Tony trusts NONE of those things.

He trusts the rail.

And that’s why his PTAC installs stay perfect for decades.

Buy this on Amazon at: https://amzn.to/3WuhnM7

In the next topic we will know more about: If You Don’t Square the Sleeve, You Already Lost — Tony’s Rule for 12k PTAC Wall Cuts That Never Leak or Shift