🌱 Introduction: The Green Shift in Heating and Cooling

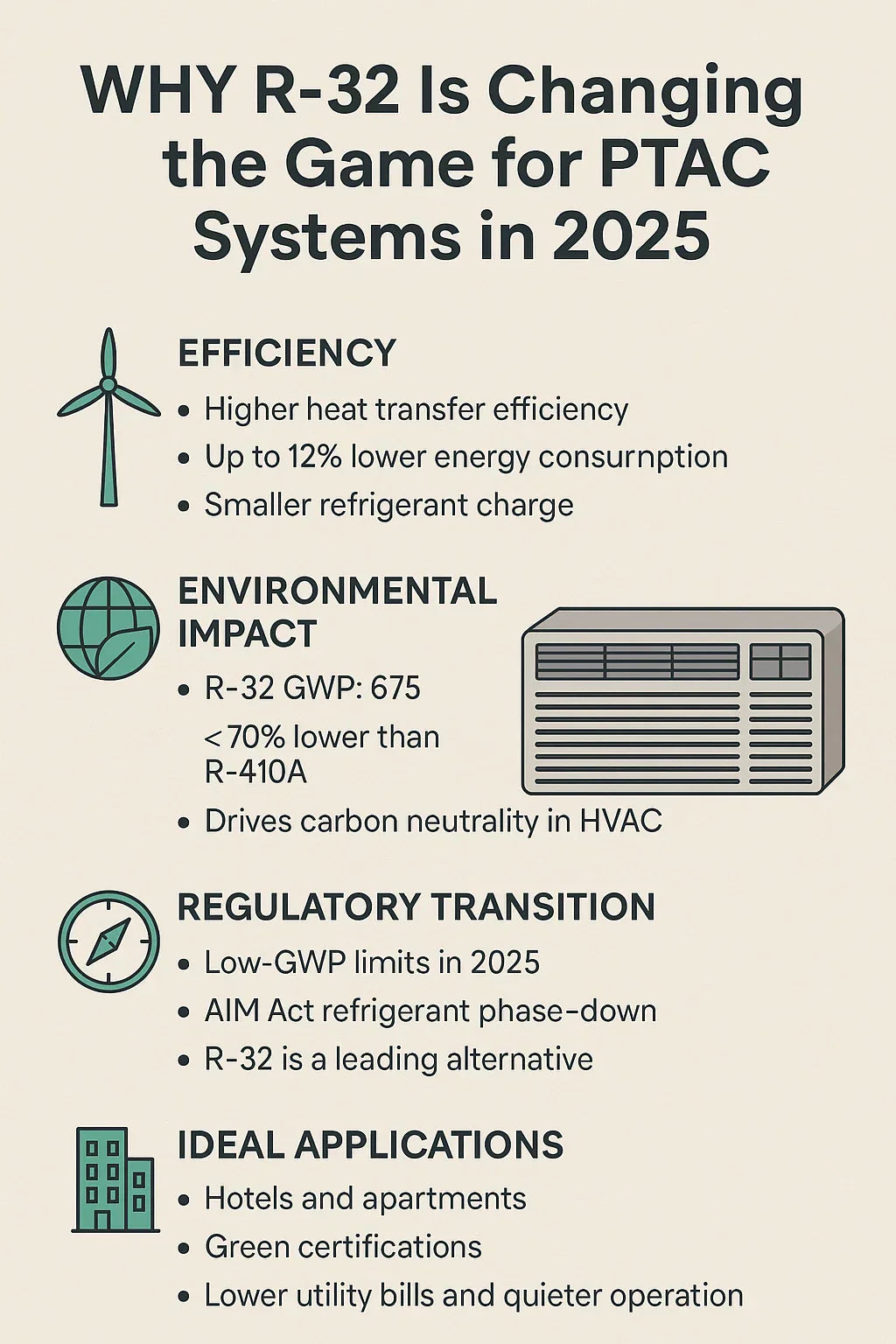

If you’ve been keeping an eye on HVAC trends, you’ve probably noticed three letters popping up everywhere lately: R-32. This new refrigerant is more than a technical update — it’s the cornerstone of a global movement toward sustainability in heating and cooling systems.

In 2025, the U.S. is entering a new era of refrigerant regulation under the EPA’s AIM Act, which phases down high-GWP (Global Warming Potential) refrigerants like R-410A. And when it comes to PTAC systems (Packaged Terminal Air Conditioners) — the units commonly used in hotels, apartments, dorms, and offices — R-32 is leading the charge.

This isn’t just about compliance; it’s about efficiency, climate responsibility, and long-term cost savings. In this deep dive, we’ll explore why R-32 PTAC units are revolutionizing the HVAC landscape in 2025, how they differ from traditional systems, and what this shift means for homeowners, property managers, and sustainability-minded professionals.

⚡ What Exactly Is R-32?

R-32 (difluoromethane) is a single-component refrigerant that’s quickly becoming the global standard for modern HVAC systems. It’s part of the hydrofluorocarbon (HFC) family — but unlike older blends, R-32 delivers higher efficiency and a dramatically lower environmental impact.

Here’s what makes it stand out:

| Feature | R-32 | R-410A |

|---|---|---|

| Type | Single refrigerant | Blend (R-32 + R-125) |

| GWP (Global Warming Potential) | 675 | 2088 |

| Refrigerant charge | ~20% less | Higher |

| Energy efficiency | Superior | Moderate |

| Reusability | Easily recycled | Difficult to separate |

According to the U.S. Department of Energy (DOE), R-32’s lower GWP makes it one of the most environmentally conscious refrigerants available today — aligning perfectly with the new federal standards coming into force in 2025.

🌬️ PTAC Systems 101 — Why This Matters

Before diving deeper, let’s clarify what a PTAC unit does.

A Packaged Terminal Air Conditioner (PTAC) is a self-contained heating and cooling system that’s installed through a wall, typically found in:

-

Hotels and motels

-

Apartments and condos

-

Senior living facilities

-

Offices or classrooms

Because PTAC units manage climate control room by room, they’re efficient, flexible, and ideal for spaces that don’t require central air.

However, traditional PTAC systems using R-410A refrigerant have faced challenges with energy consumption and carbon emissions. This is where R-32 technology truly shines — it maintains all the simplicity of PTAC design while dramatically improving performance, cost efficiency, and eco-friendliness.

🔋 Efficiency That Speaks for Itself

R-32 refrigerant doesn’t just meet the new standards — it exceeds them.

✅ Higher Heat Transfer Efficiency

R-32 has a superior heat transfer coefficient, which allows PTAC units to cool or heat spaces faster while using less electricity. This translates into real-world energy savings and reduced operating costs.

✅ Up to 12% Lower Energy Consumption

Independent testing and Energy Star® studies have shown that R-32 systems can achieve up to 12% higher efficiency than R-410A equivalents. For commercial buildings with dozens of PTAC units, that can mean thousands of dollars saved annually.

✅ Smaller Refrigerant Charge

Since R-32 is more efficient per unit volume, PTAC manufacturers use up to 30% less refrigerant per system. This reduces both manufacturing cost and potential environmental impact if a leak occurs.

🌡️ The Environmental Impact — Why GWP Matters

The Global Warming Potential (GWP) of a refrigerant measures how much heat it traps in the atmosphere relative to carbon dioxide (CO₂ = GWP 1).

-

R-410A has a GWP of 2088.

-

R-32 has a GWP of 675 — that’s nearly 70% lower.

In other words, even if an R-32 PTAC unit leaks, its climate impact is dramatically smaller than that of a comparable R-410A system.

According to the EPA’s Greenhouse Gas Equivalencies Calculator, switching a 100-room property from R-410A PTACs to R-32 could prevent thousands of pounds of CO₂-equivalent emissions every year.

🧭 The 2025 Refrigerant Transition Explained

Beginning in 2025, the EPA will require HVAC manufacturers to comply with new low-GWP limits for refrigerants used in comfort cooling applications.

This is part of the American Innovation and Manufacturing (AIM) Act, which mandates a 40% reduction in HFC usage by 2028 and an 85% reduction by 2036.

To meet these goals, manufacturers are moving toward refrigerants like:

-

R-32

-

R-454B (blend alternative)

-

R-1234yf (used in some automotive systems)

Among these, R-32 stands out as the most efficient, cost-effective, and globally adopted refrigerant for PTAC and mini-split systems.

According to ASHRAE, over 150 million R-32 units have already been installed worldwide — proof that this transition is both practical and scalable.

🏨 Perfect for Hotels, Apartments & Multi-Room Properties

For building managers and developers, R-32 PTACs are a dream come true. They offer:

🏢 1. Easier Retrofits

Because R-32 PTACs are often mechanically compatible with existing R-410A sleeves and electrical setups, upgrading doesn’t require major construction or rewiring.

🧾 2. Lower Utility Bills

Thanks to higher EER (Energy Efficiency Ratio) performance, R-32 systems lower monthly operating costs. That’s especially valuable for hotels or senior living facilities running dozens of units 24/7.

💨 3. Quieter Operation

Modern R-32 PTACs use inverter technology, enabling variable speed operation and quieter indoor performance — enhancing comfort for guests or tenants.

🌎 4. Green Marketing Advantage

Sustainability sells. Property owners can showcase their R-32 PTACs as part of LEED, Energy Star, or Green Key certifications, appealing to environmentally conscious travelers and tenants alike.

According to Green Building Council data, energy-efficient HVAC upgrades can increase building value by up to 10% and reduce maintenance costs over time.

🧰 Installation & Maintenance — Easier Than You Think

Despite its advanced refrigerant, installing an R-32 PTAC system isn’t complicated.

🪚 1. Installation Overview

Most R-32 PTACs use the same wall sleeve dimensions as legacy models. The process typically involves:

-

Removing the old unit

-

Cleaning and prepping the wall sleeve

-

Sliding the new PTAC into place

-

Connecting power and sealing the perimeter

Because R-32 operates at similar pressures to R-410A, technicians familiar with existing systems can adapt easily.

🧼 2. Maintenance Simplicity

Routine maintenance — such as filter cleaning, coil brushing, and drain pan checks — remains unchanged.

Technicians, however, must use R-32-compatible gauges and tools, and follow EPA Section 608 refrigerant handling guidelines.

🔥 Performance in All Seasons

One common misconception is that eco-friendly refrigerants compromise heating power — but R-32 PTACs prove the opposite.

❄️ Superior Cooling Performance

R-32 transfers heat more efficiently, allowing PTACs to deliver faster cooling even in hot, humid climates.

🔥 Reliable Heating Support

Many R-32 PTACs include heat pump capability, supported by backup electric resistance heat for colder days.

Tests show that R-32 systems maintain stable performance down to 20°F (-6°C) — making them suitable for most U.S. regions.

💧 Better Humidity Control

Because R-32 improves coil temperature uniformity, PTACs using this refrigerant also provide enhanced dehumidification, creating a more comfortable indoor climate.

🧮 Real-World Energy Savings Example

Let’s run a simple comparison for a mid-size hotel property:

| Parameter | R-410A PTAC | R-32 PTAC |

|---|---|---|

| Cooling capacity | 12,000 BTU | 12,000 BTU |

| EER | 9.5 | 11.0 |

| Average usage | 10 hrs/day | 10 hrs/day |

| Annual kWh | ~3,950 | ~3,410 |

| Cost per kWh | $0.14 | $0.14 |

| Annual Energy Cost | $553 | $477 |

That’s $76 saved per unit per year — and if you have 50 PTACs, that’s nearly $3,800 in yearly savings.

Now factor in reduced maintenance and potential tax incentives, and the long-term ROI becomes even stronger.

🧾 Rebates, Tax Credits & Incentives

Sustainability pays — literally.

As of 2025, several programs offer financial incentives for upgrading to low-GWP, energy-efficient HVAC equipment:

-

ENERGY STAR Rebate Finder lists state and utility rebates for qualifying PTACs.

-

The Inflation Reduction Act (IRA) provides tax credits for high-efficiency systems that meet DOE standards.

-

Certain states offer performance-based incentives for commercial properties reducing overall energy demand.

Switching to an R-32 PTAC could qualify you for both federal and local savings — helping offset the cost of equipment and installation.

🧪 Safety: Addressing the A2L Question

Yes — R-32 is classified as an A2L refrigerant, meaning mildly flammable. But context is key.

Modern R-32 PTACs are engineered with safety in mind, featuring:

-

Leak detection sensors

-

Ignition-proof components

-

Flame-retardant materials

-

Strict compliance with ASHRAE Standard 15 and UL 60335-2-40

When installed properly by licensed professionals, R-32 systems are just as safe as traditional units — a conclusion supported by global usage across millions of installations.

According to Daikin’s R-32 Safety Report, “no serious accidents” related to R-32 use have been reported in over a decade of widespread adoption.

🌎 The Global Perspective — Why R-32 Leads Worldwide

R-32 isn’t new; it’s just new to the U.S. market on a large scale.

Countries like Japan, Australia, and members of the EU have been using R-32 systems since 2013 — collectively cutting millions of tons of CO₂ emissions.

-

Japan: 99% of new residential air conditioners now use R-32.

-

Europe: R-410A has been largely phased out under the F-Gas Regulation.

-

Australia: National refrigerant transition programs endorse R-32 for small-capacity systems.

The U.S. is simply catching up, and 2025 marks the turning point.

Manufacturers such as GE, Amana, and LG are already releasing R-32 PTAC and mini-split models designed to meet or exceed SEER2 and DOE 2025 standards.

🧩 Why Single-Component Refrigerants Are the Future

R-32’s single-component chemistry makes it easier to recycle, recover, and reuse — unlike blended refrigerants (like R-410A), which are difficult to separate and often discarded.

This supports a circular economy approach, where refrigerant can be purified and reused instead of destroyed.

It also simplifies maintenance: if a leak occurs, technicians can top off R-32 rather than evacuating and replacing the full charge.

🪴 Sustainability Beyond the Tech

For Savvy homeowners and property managers, choosing R-32 isn’t just a compliance move — it’s a statement of intent. It shows that you value:

-

Long-term energy efficiency

-

Reduced carbon footprint

-

Lower lifecycle environmental impact

-

Smarter use of natural resources

By embracing refrigerants like R-32, you’re helping move the HVAC industry toward a more sustainable, regenerative model — one where comfort and climate responsibility coexist beautifully.

🏁 Final Thoughts — Why R-32 Is the Smart Choice for 2025 and Beyond

R-32 isn’t a trend — it’s the foundation of the future in HVAC.

Whether you manage a boutique hotel, retrofit apartments, or simply want your property to be future-proof, R-32 PTAC systems deliver the trifecta:

✅ Lower emissions

✅ Higher energy efficiency

✅ Lower operating costs

As the U.S. enters the 2025 refrigerant transition, the smartest move is to get ahead — and invest in a technology that’s clean, compliant, and cost-saving.

In the next topic we will know more about: How Much Energy Can You Really Save with an R-32 PTAC?