The Startup Pause That Saves Compressors, Efficiency, and Your Reputation

If there’s one habit that separates clean startups from future callbacks, it’s this:

I don’t rush refrigerant.

I don’t care how good the install looks.

I don’t care how clean the brazes are.

I don’t care how confident the numbers seem.

On modern systems—especially R-32 condensers like the Goodman GLXS3B3010—refrigerant adjustments made too early do more harm than almost any other startup mistake.

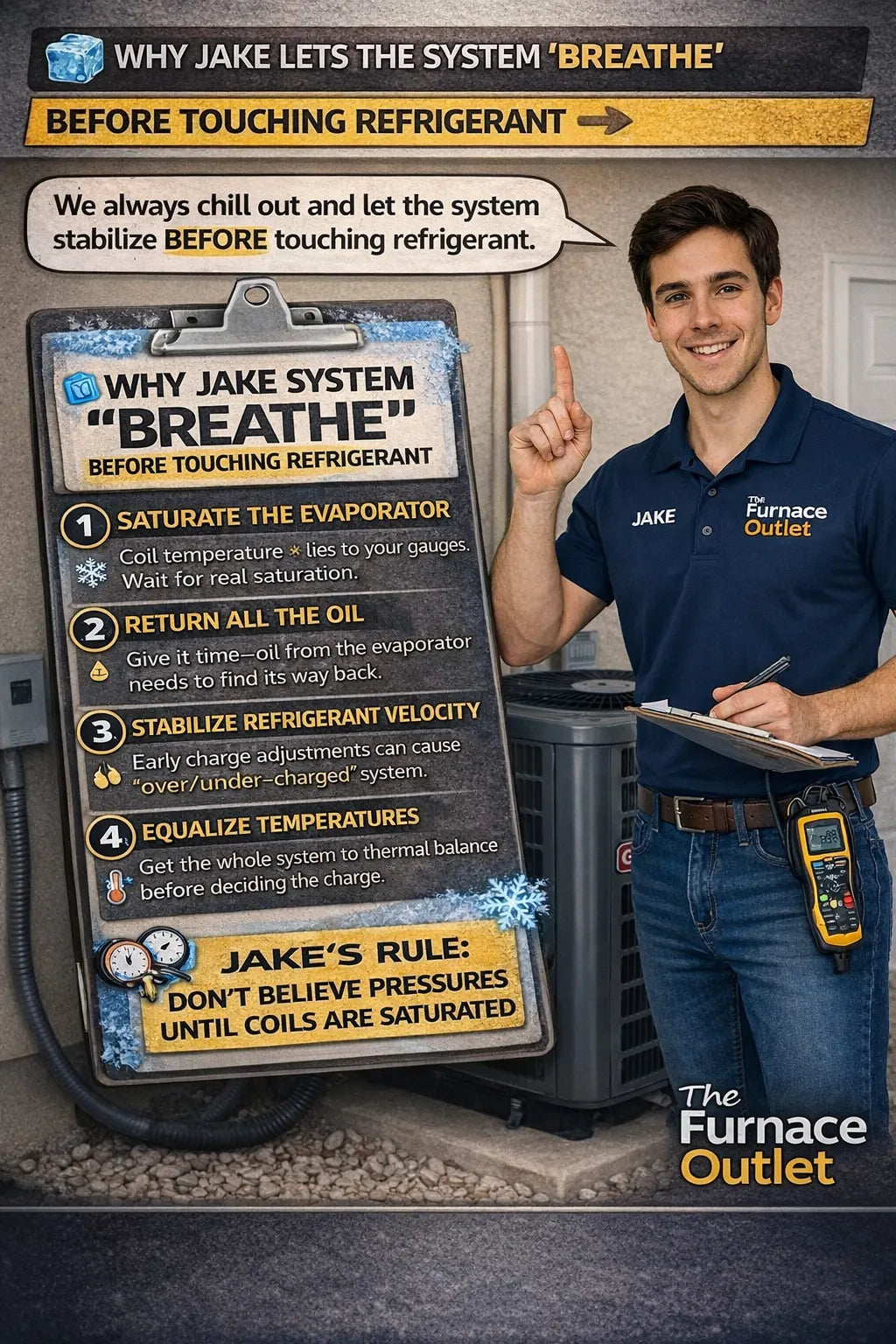

That’s why I let the system breathe.

Not idle.

Not ignored.

Stabilized.

🧠 What “Letting the System Breathe” Actually Means

Let’s clear up the confusion right away.

Letting the system breathe does not mean:

-

Walking away for an hour

-

Ignoring abnormal sounds

-

Letting pressures run uncontrolled

Breathing means giving the system enough uninterrupted runtime to:

-

Fully saturate the evaporator coil

-

Circulate oil through the entire loop

-

Stabilize refrigerant velocity

-

Equalize temperatures across components

Until that happens, your gauges are lying to you.

⏱️ Why Early Pressure Readings Can’t Be Trusted

The first 5–10 minutes of runtime are deceptive.

During that window:

-

Coil temperatures are uneven

-

Oil is still migrating

-

Refrigerant density is changing by the minute

Low suction pressure early does not automatically mean low charge.

High head pressure early does not automatically mean overcharge.

Yet this is exactly when most techs start adjusting.

That’s not tuning.

That’s guessing.

🌡️ Why R-32 Makes Impatience Even More Dangerous

R-32 is efficient, responsive, and unforgiving.

Compared to older refrigerants:

-

Pressure reacts faster

-

Temperature swings register immediately

-

Small charge errors show up later, not right away

That creates false confidence.

A rushed adjustment might look perfect at minute 12…

…and run hot, loud, and inefficient for the next 12 years.

R-32 doesn’t punish mistakes loudly.

It punishes them quietly and permanently.

🔄 What’s Actually Happening While the System Breathes

Inside the system, several critical processes are unfolding at once:

-

Oil is returning from the evaporator

-

Refrigerant velocity is settling

-

Coil surface temperatures are evening out

-

The compressor is establishing its thermal rhythm

None of that shows clearly on gauges.

But all of it determines whether your final charge will be right—or wrong for the life of the unit.

👂 What Jake Watches Instead of Gauges

I’m not standing there doing nothing.

During the breathing window, I’m watching and listening for:

-

Compressor sound consistency

-

Fan stability

-

Cabinet vibration

-

Line set temperature change by hand

If something is wrong, I’ll feel it or hear it before gauges confirm it.

Experience beats instruments during this phase.

⚠️ The Overcharge Spiral Nobody Talks About

Here’s how most systems get quietly ruined:

-

Early low pressure is observed

-

Refrigerant is added

-

System stabilizes

-

Head pressure climbs

-

Efficiency drops permanently

-

Compressor runs hot forever

No alarms.

No immediate failure.

Just shortened life.

Letting the system breathe breaks this cycle completely.

🧪 When Jake Finally Connects Gauges (and Why)

I don’t connect gauges until:

-

Airflow is confirmed

-

Runtime is sufficient

-

Indoor and outdoor temps are logged

Why?

Because refrigerant is the last variable, not the first.

Charging before airflow and stabilization is like aligning a car before tightening the suspension—it looks right, but it isn’t.

🧰 Tools I Trust During the Breathing Window

During this phase, I keep tools minimal:

-

Reliable thermometer

-

Clamp meter

-

My hands and ears

🏗️ Why This Matters on the Goodman GLXS3B3010

The Goodman 2.5-Ton 13.4 SEER2 R-32 condenser is a solid, honest system—if you respect its startup needs.

This unit:

-

Responds quickly to charge changes

-

Holds efficiency when charged correctly

-

Suffers quietly when rushed

For refrigerant handling best practices, I align with EPA guidance:

🔗 https://www.epa.gov/section608

📋 Jake’s Breathing Checklist

Before I touch refrigerant, I confirm:

-

Stable operation

-

Verified airflow

-

Even temperature spread

-

No abnormal sounds

If any of those aren’t true, refrigerant stays untouched.

🧠 Jake’s Rule of Thumb

If the system hasn’t:

-

Settled

-

Smoothed out

-

Shown me its rhythm

…I don’t tune it.

Charging isn’t a race.

It’s a responsibility.

🔑 Jake’s Final Word

Every system I’ve trusted to breathe has paid me back with:

-

Better efficiency

-

Quieter operation

-

Fewer callbacks

Every system I’ve seen rushed?

It aged early.

Remember this and you’ll avoid more problems than any gauge set ever could:

Refrigerant is the last thing you adjust—never the first.

Buy this on Amazon at: https://amzn.to/47dm4yJ

In the next topic we will know more about: Startup Voltage Isn’t Line Voltage: Jake’s Real Load-Test Method