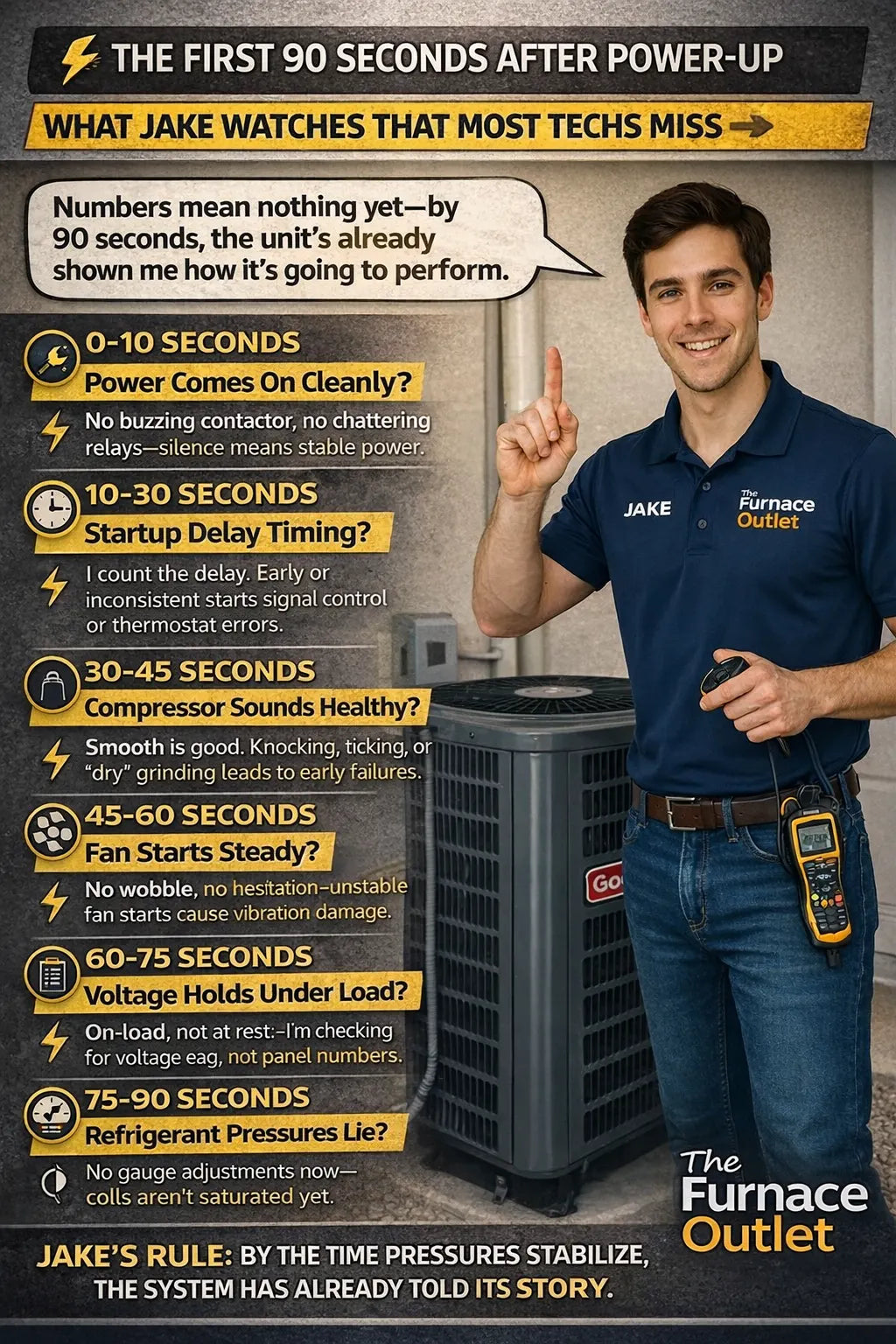

⚡ The First 90 Seconds After Power-Up

What Jake Watches That Most Techs Miss (and Why It Decides the System’s Future)

If I had to diagnose half the systems I’ve ever fixed, I wouldn’t need gauges, laptops, or error codes.

I’d just need to rewind the clock and stand there for the first 90 seconds after power-up.

That window tells the truth.

Not the “manual truth.”

Not the “textbook truth.”

The real-world truth about whether the system was installed with intention—or rushed into service.

This article walks through exactly what I watch on a modern R-32 condenser like the Goodman 2.5-Ton 13.4 SEER2 GLXS3B3010, starting the instant power is applied.

No fluff. No guessing. Just behavior.

🧠 Why the First 90 Seconds Matter More Than the First 90 Minutes

Modern systems are smarter than ever—but that also means they’re less forgiving.

Boards, contactors, and compressors make decisions immediately:

-

How clean the power is

-

Whether timing sequences are respected

-

How mechanical components react under first load

By the time pressures “look normal,” damage may already be done.

That’s why I don’t chase numbers first.

I watch how the system behaves when it wakes up.

🔌 Seconds 0–10: Does the System Accept Power Calmly?

The moment I close the disconnect, I stop moving.

I’m listening.

A healthy system powers up quietly:

-

No frantic relay clicking

-

No buzzing contactor

-

No flickering lights at the unit

What I don’t want to hear is hesitation.

If a board chatters or relays cycle rapidly, that tells me something upstream is unstable—usually grounding, voltage, or control wiring.

If power doesn’t arrive cleanly, nothing downstream will behave correctly.

⏱️ Seconds 10–30: Startup Delay Timing Never Lies

Every manufacturer programs intentional delays. Goodman is no exception.

I count the delay—literally.

If the condenser fan or compressor engages:

-

Too fast

-

Too slow

-

Or inconsistently

…I already know there’s an issue.

Delay timing problems usually point to:

-

Thermostat misconfiguration

-

Control voltage instability

-

Wiring mistakes that will cause callbacks

Timing isn’t cosmetic.

It’s how the system protects itself.

🔊 Seconds 30–45: Compressor Sound Is a Diagnostic Tool

Before I ever touch a gauge, I use my ears.

A healthy R-32 compressor sounds:

-

Smooth

-

Even

-

Confident

Red flags include:

-

Hollow knocking

-

Sharp metallic ticks

-

A “dry” mechanical sound

Those noises don’t always mean failure today—but they almost always mean trouble later.

A compressor tells you how it feels.

Most techs just don’t listen.

🌬️ Seconds 45–60: Fan Start Signature Matters

I watch the condenser fan closely during its first engagement.

I’m checking for:

-

Wobble

-

Hesitation

-

Oscillation or harmonic noise

A fan that surges or vibrates on startup will transfer that energy into the cabinet, coil, and line set over time.

That’s how “mystery noises” show up weeks later—after the installer is long gone.

⚡ Seconds 60–75: Load Voltage Is the Only Voltage That Matters

Now I grab the meter.

But not to check line voltage at rest.

I check voltage under load, right as the compressor is running.

Why?

Because unloaded voltage lies.

I’m looking for:

-

Excessive voltage drop

-

Imbalance between legs

-

Signs of weak supply or loose connections

If voltage collapses during startup, the compressor is already under stress—even if it keeps running.

For grounding and voltage standards, I follow NEC guidance:

🔗 https://www.nfpa.org

🧊 Seconds 75–90: Refrigerant Is Still Lying to You

This is where most mistakes happen.

At 90 seconds:

-

Oil hasn’t fully circulated

-

The coil isn’t saturated

-

Pressures are not meaningful

I do not adjust charge here.

I don’t even connect gauges unless something sounds wrong.

Chasing pressures too early causes:

-

Overcharging

-

Misdiagnosis

-

Long-term efficiency loss

Patience protects compressors.

🚫 What Jake Does NOT Do in the First 90 Seconds

Let’s be clear.

I do NOT:

-

Adjust refrigerant

-

Change blower speeds

-

Override safeties

-

Ignore odd sounds

The first 90 seconds are for observation—not intervention.

🧰 Tools I Trust During Early Startup

At this stage, I only use tools that don’t interfere with system behavior:

-

Quality multimeter

-

Reliable clamp meter

-

My ears

🏗️ Why This Matters on the Goodman GLXS3B3010

The Goodman 2.5-Ton 13.4 SEER2 R-32 condenser is a solid, no-nonsense platform—if it’s started correctly.

This unit will:

-

Reveal voltage issues early

-

Expose airflow problems quickly

-

Punish rushed startups quietly

🧠 Jake’s Rule of Thumb

Every great startup I’ve done felt boring.

Quiet.

Predictable.

Uneventful.

Every bad system I’ve ever been called to fix?

It was screaming in the first minute—no one was listening.

🔑 Jake’s Final Word

If you miss the first 90 seconds, you miss the truth.

Numbers come later.

Stability comes first.

Startup isn’t about how fast you can finish—it’s about how long the system will last after you leave.

Buy this on Amazon at: https://amzn.to/47dm4yJ

In the next topic we will know more about: Why Jake Lets the System ‘Breathe’ Before Touching Refrigerant