By Tony — because a blower can’t pull air that isn’t there.

🔥 1. Introduction — The Return-Side Disaster Waiting to Happen

I’ve been in attics, crawlspaces, and garages for more than 30 years.

I’ve seen cracked heat exchangers, burned-out ECM motors, noisy ducts, and sweaty coil cabinets.

But if you ask me what causes the most expensive failures in HVAC installs that homeowners never see coming?

It’s this:

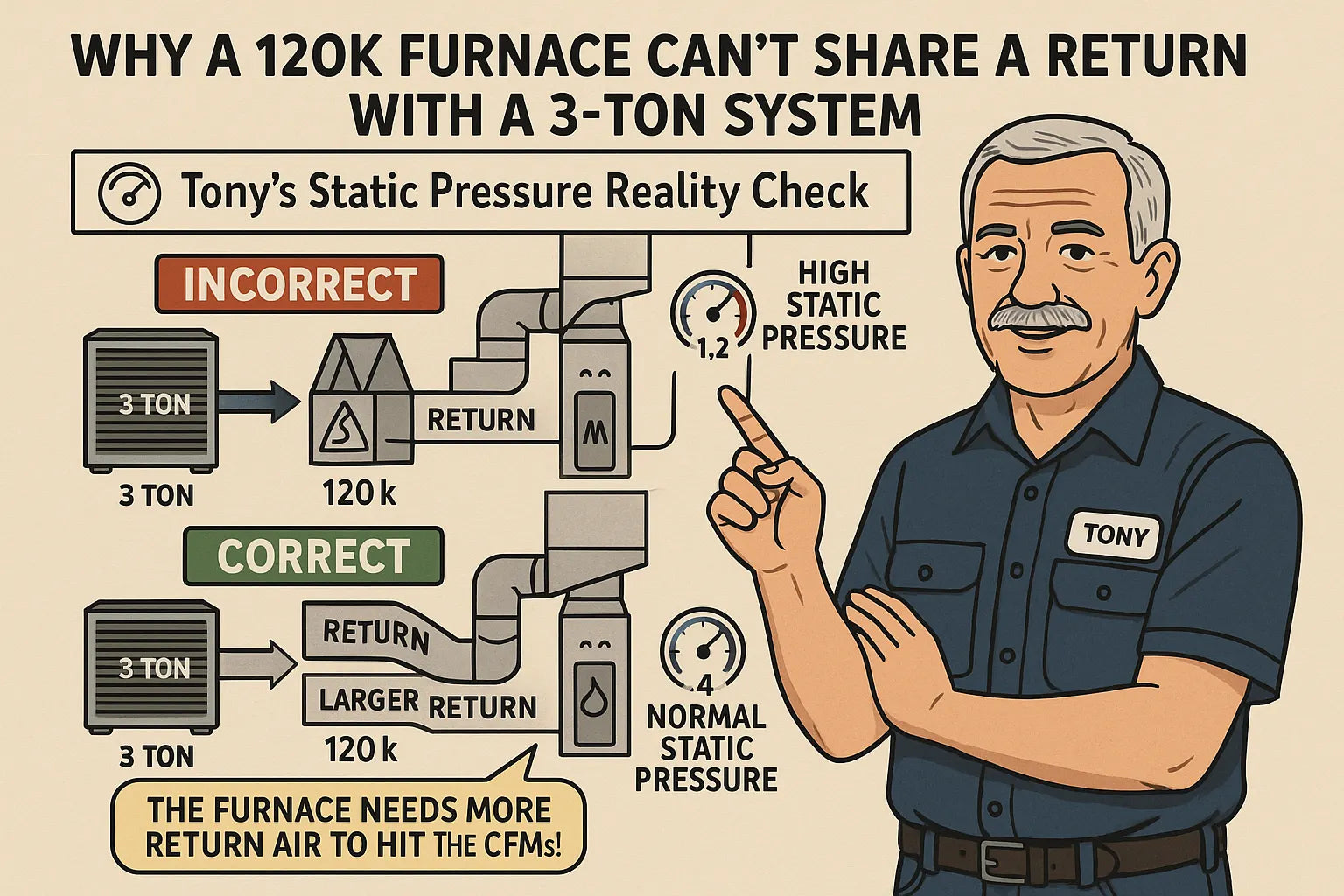

Oversized furnace + undersized return.

And the most common version of that mistake is when someone tries to run a 120,000 BTU furnace on the same return as a 3-ton AC or heat pump — without changing anything about the ductwork.

Let me be blunt:

-

The blower is starving.

-

The furnace is suffocating.

-

The coil is choking.

-

The static pressure is skyrocketing.

-

And the system will eventually fail, guaranteed.

A 120k furnace is a high-input, high-airflow, high-demand machine.

A 3-ton system has very specific airflow requirements.

When they share a return that’s undersized for one — let alone both — everything goes sideways.

Today I’m going to break down exactly why this happens, how the physics works, and how to design a system that never starves for air.

🌀 2. The Airflow Basics Most Installers Ignore

Here’s the first rule every installer should tattoo on their arm:

Heating airflow and cooling airflow are not the same thing.

Cooling Airflow (3-Ton System)

3 tons × 400 CFM per ton = 1,200 CFM

That’s the minimum required airflow across the coil.

Heating Airflow (120k Furnace)

Most 120,000 BTU furnaces require 1,600–2,000+ CFM depending on temperature rise.

Those two numbers should jump out at you:

1,200 CFM (cooling) vs. 1,600–2,000 CFM (heating)

That’s a 400–800 CFM difference — which is enormous.

Now here’s the part rookies don’t understand:

You can’t pull 2,000 CFM through a return that’s only sized for 1,200 CFM.

The duct doesn’t magically grow when the furnace turns on.

The filter doesn’t get bigger.

The return drop doesn’t widen.

The grill doesn’t expand.

So what happens?

You get excessive static pressure — the silent killer of HVAC systems.

📈 3. What Is Static Pressure — And Why It Destroys Equipment?

Static pressure is the “blood pressure” of your system.

A properly designed system should run around:

-

0.5″ WC total external static pressure (TESP)

(AHRI/ASHRAE recommendations)

When you starve a blower for air, that number climbs.

Fast.

I’ve measured systems running:

-

0.9″ WC

-

1.2″ WC

-

Even 1.6″ WC

Most ECM blowers are rated for a maximum of 0.8″ WC.

Go past that?

You get:

-

Blower overheating

-

Excessive amp draw

-

Premature ECM burnout

-

Noisy airflow

-

Whistling returns

-

Filter “slapping”

-

Reduced airflow

-

Reduced cooling capacity

-

Coil freeze-ups

-

Failed limit switches

-

Furnace overheating

-

Cracked heat exchangers (the big one)

Static pressure is not a suggestion.

It’s physics.

🧮 4. The Math the Installer Must Do — Tony’s Reality Check

Let’s run the real numbers using standard duct sizing.

A typical 3-ton return system

Designed for 1,200 CFM.

Common duct sizes:

-

16" x 25" filter

-

14" or 16" return drop

-

One 16x25 or 18x20 return grille

This is barely enough for cooling, and already borderline for quiet operation.

But a 120k furnace needs 1,600–2,000 CFM

That requires:

-

At least (2) 16" returns

-

Or (3) 14" returns

-

Or one 20" + one 16" return

-

Filter area of ≥30–40 sq. in per 1,000 CFM

-

A return drop of 18"–20" minimum

Which means:

A single 3-ton return system is physically incapable of feeding a 120k furnace.

The math never lies.

🔍 5. What Actually Happens When You Try to Share a Return

✔️ 1. Blower ramps up to max speed (ECM panic mode)

It’s trying to hit target airflow, but it can’t.

✔️ 2. Static pressure spikes

You may hear:

-

Whistling

-

Cabinet rumble

-

Filter slapping

-

Return grille “howling”

✔️ 3. Temperature rise skyrockets

Because low airflow = hotter heat exchanger.

Furnace nameplates list acceptable temperature rise:

A typical 120k furnace:

40°F–70°F rise

Undersized return systems hit:

80°F… 90°F… 110°F…

That’s a cracked heat exchanger waiting to happen.

✔️ 4. Limit switch trips

The furnace shuts down.

Customer thinks the “furnace is broken.”

✔️ 5. Coil starves for airflow

No air = no heat exchange.

Cooling capacity drops 20–50%.

✔️ 6. Coil freezes on cooling mode

And if it thaws fast?

The drain pan can overflow.

🧊 6. Why Tony Never Installs a Furnace Without Checking Return CFM First

Every single heat or cooling problem can be traced back to:

-

Air not moving

-

Air not moving fast enough

-

Air not moving evenly

A furnace doesn’t “make heat.”

It moves heat.

An AC doesn’t “make cold.”

It moves heat.

Airflow is the engine.

Static pressure is the resistance.

So before I install a 120k furnace, I check:

✔️ Return grille area

Rule of thumb:

2 square feet per 1,000 CFM

✔️ Filter size

Minimum for 2000 CFM:

20" x 25" + 16" x 25"

(or one 30" x 30")

✔️ Return drop size

Must be 18" or greater.

✔️ Duct sizing

Return duct must equal or exceed:

-

800 sq. in of duct cross-section

(according to ACCA Manual D sizing)

✔️ Total External Static Pressure reading (TESP)

If it's above 0.5" WC, the system is already in trouble.

🧱 7. Why a 120k Furnace Was Never Meant for a 3-Ton Home

Let’s talk system design reality.

A house requiring:

-

3 tons of AC (36,000 BTU)

… typically needs 60,000–80,000 BTU of heat.

A 120,000 BTU furnace is oversized for:

-

The ducts

-

The return

-

The rooms

-

The load

-

The blower

-

The house

When you put a 120k furnace under a 3-ton system, you’re pairing:

-

Huge heating airflow

with -

Modest cooling airflow

And trying to shove both through the same ductwork.

That’s like putting a Hellcat engine in a Honda Civic and keeping the same fuel lines.

Something will fail.

🧰 8. How Tony Fixes This Problem on Real Jobsites

Here’s how pros do it.

✔️ 1. Add a second full return path

Usually another 16" or 20" return.

✔️ 2. Increase filter size

I often upgrade to:

-

A 4" media filter

-

A larger cabinet

-

Dual-filter system

✔️ 3. Rebuild the return drop

Especially if the furnace is in:

-

A closet

-

A garage

-

A basement corner

-

A tight attic platform

✔️ 4. Change blower speed settings

Only after duct corrections — not before.

✔️ 5. Recalculate temperature rise

A properly fed furnace always hits target rise.

✔️ 6. Reduce furnace size if appropriate

Oversized equipment kills airflow.

Proper sizing saves everything.

📘 9. Verified External Technical Resources

Here are reputable, verified external resources supporting coil installation, condensate management, and TXV behavior:

-

ASHRAE Fundamentals – Coil Construction & Airflow (Technical)

https://www.ashrae.org/technical-resources/ashrae-handbook -

HVAC Drainage Code Requirements (ICC)

https://codes.iccsafe.org/ -

EPA HVAC Moisture & Condensate Guidelines

https://www.epa.gov/mold -

AHRI Air Coil Performance Standards

https://www.ahrinet.org/standards -

RSES TXV Installation & Superheat Guidelines

https://www.rses.org -

Goodman (Daikin) Coil & TXV Transition Resources

https://www.daikincomfort.com/

🏁 10. Final Words — You Can’t Cheat Physics, and the System Always Wins

Let me say this clearly:

A 120k furnace cannot breathe through a 3-ton return system.

It doesn’t matter:

-

How smart your thermostat is

-

How variable your ECM blower is

-

How “powerful” the furnace is

-

How tight your flares are

-

How good your startup was

If the return is undersized:

-

The furnace overheats

-

The coil starves

-

The blower dies

-

The ducts scream

-

The utility bill spikes

-

The rooms never feel right

And eventually, something fails in a way that costs real money.

This is why every furnace install starts with one question:

“How much air can this return actually move?”

If the answer isn’t “enough,”

you don’t install the furnace until it is.

Buy this on Amazon at: https://amzn.to/47z1067

In the next topic we will know more about: The 4-Ton R-32 Sweep Bend — Tony’s Rule for Getting Suction Lines Around Tight Corners Without Killing Capacity