By Tony — because a coil that’s “good enough” never is.

🧊 1. Introduction — The Coil Problem Nobody Talks About

Every installer knows how to drop a vertical evaporator coil into a cased housing.

Every manufacturer claims their coil is “plug-and-play.”

And every rookie thinks once the screws bite, the coil is done.

Let me be real with you:

Vertical coils lie.

The CAPTA6030D3 lies beautifully.

On day one, they always look like they’re sitting right.

On day two, once refrigerant flows, heat exchange begins, and the cabinet expands,

the coil shifts — just enough to ruin drainage, airflow, or metering.

That’s why on every Goodman 4-ton R-32 system I install, I never lock that CAPTA6030D3 coil into place until I’ve set it twice:

-

A dry set (mechanical alignment and cabinet geometry)

-

A wet set (thermal-expansion alignment once refrigerant and airflow start behaving)

This is why most contractors have callbacks for water leaks, sweating cabinets, noisy airflow, and uneven frost patterns.

It’s not the refrigerant.

It’s not the charge.

It’s not the blower speed.

It’s the coil not being set twice.

And today, I’m going to show you exactly how the pros do it.

🛠️ 2. Why the CAPTA6030D3 Is a Different Animal (Especially With R-32)

Goodman’s CAPTA6030D3 is a 30-inch tall, vertical, A-coil designed for high-efficiency systems, including their new R-32 lineup.

The performance is fantastic — when it’s installed right.

But this coil has three characteristics that make a rookie installation a disaster:

✔️ 1. It expands more than older R-410A coils

R-32 runs hotter and carries heat faster.

That means:

-

The tubing expands more.

-

The coil shifts slightly in the housing.

-

The alignment you saw during the dry set is no longer the alignment during operation.

✔️ 2. The internal pan angle is critical

If the coil leans even a fraction toward the wrong rail:

-

Water pools on the wrong side

-

Pan overflows

-

Water runs down the furnace cabinet

-

Then the homeowner thinks the “furnace is leaking”

Most installers think the pan angle is built-in.

It is — but only if the coil sits exactly where Goodman intended.

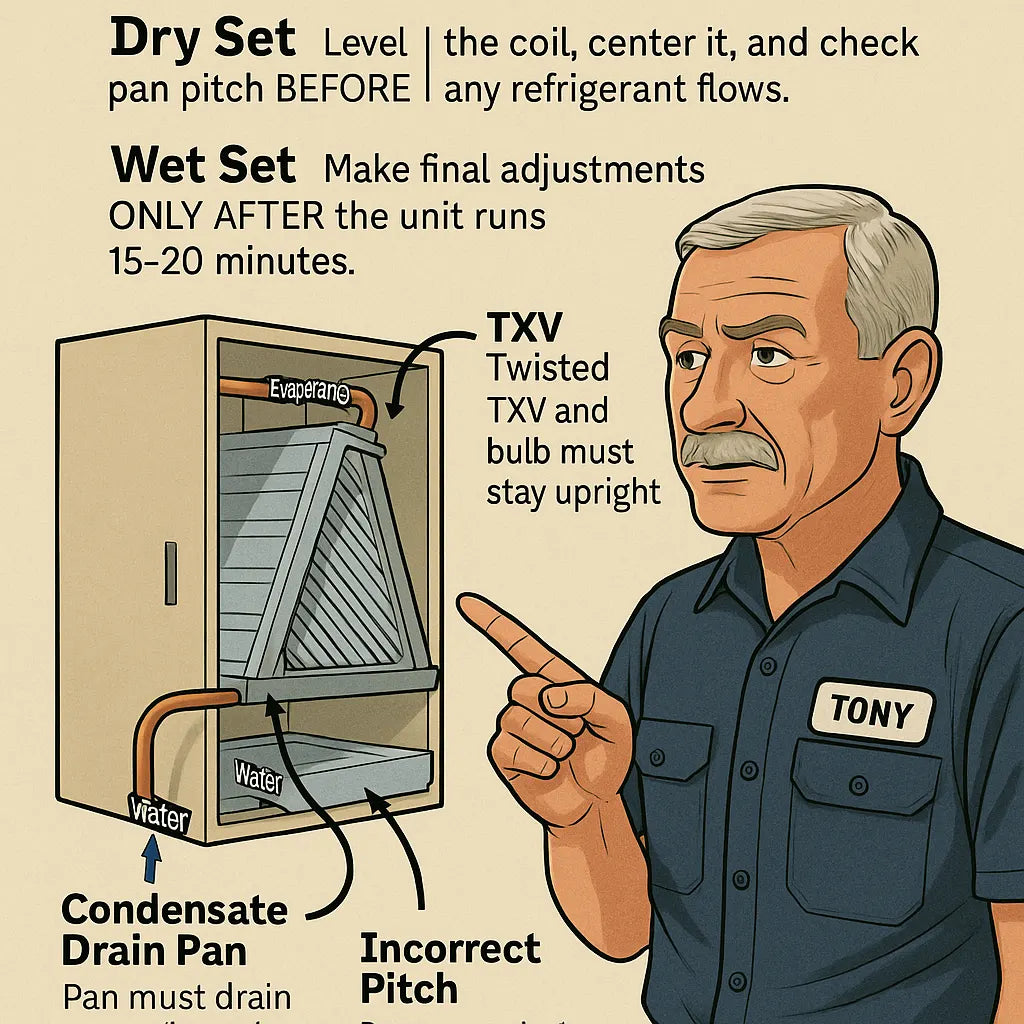

✔️ 3. The TXV must stay perfectly upright

TXVs do not like being twisted.

They don’t like being torqued sideways.

And on a vertical coil, even tiny shifts change how the sensing bulb sees suction temperature.

This affects:

-

Superheat

-

Frost pattern

-

Total capacity

-

Comfort

-

Noise levels

This is why I tell people:

R-32 didn’t change the install. The coil did.

The refrigerant amplified mistakes that already existed.

📐 3. The Coil Isn’t Sitting Flush — It’s Sitting Where You Tell It To Sit

The CAPTA6030D3 cased coil has alignment rails, side brackets, and a built-in slope engineered into the pan.

But that slope only works if:

-

The cabinet is perfectly level

-

The furnace is perfectly level

-

The platform or slab is perfectly level

-

The coil rails are perfectly engaged

-

The cabinet is perfectly squared

And I’ll be real with you:

In the real world, nothing is level.

House framing isn’t level.

Furnace platforms aren’t level.

Closets aren’t level.

Slabs aren’t level.

So here’s Tony’s rule:

You don’t install the coil according to the house. You install the coil according to the coil.

You level everything to the coil, not the other way around.

And that requires the first set.

🧭 4. The “Dry Set” — Tony’s First Placement Before Any Refrigerant Touches the System

The dry set is where every rookie loses the game.

This is where you:

-

Align

-

Center

-

Pitch

-

Anchor

-

Square

… and then stop.

You don’t seal it.

You don’t tape it.

You don’t connect lines.

You don’t screw the front panel fully.

You don’t push the coil into its final position.

You’re just positioning and preloading the coil.

▶️ Tony’s 8-Step Dry Set Method

1. Level the furnace to within 1/8″ front-to-back and side-to-side

Not perfect — just close.

2. Dry-drop the coil into the housing with no screws

Let gravity tell you how the cabinet behaves.

3. Check pan slope with a digital level

You want at least 1/4″ per foot toward the drain side.

If not?

Shim the coil, not the furnace.

The coil’s performance matters more.

4. Check TXV orientation

The sensing bulb should be:

-

Tight

-

Insulated

-

At 4 or 8 o’clock

-

Not touching the cabinet

5. Check daylight

Shine a flashlight behind the coil from the bottom.

If you see “daylight” through the fins on one side but not the other?

The coil isn’t centered.

6. Confirm the airflow channel is balanced

The front of the coil shouldn’t choke the blower opening.

7. Set the coil back 1/8″ deeper than final position

This gives you expansion room during the wet set.

8. Temporary secure with two screws only

Just enough to prevent shifting while you run refrigerant lines.

🌀 5. Why Tony Never Finalizes a Coil Until the System Has Run for 15–20 Minutes

All metal expands.

Copper expands.

Tin-plated fins expand.

Casing expands.

The drain pan flexes.

The TXV warms up and shifts slightly.

During your first cooling cycle, the entire coil:

-

Moves

-

Flexes

-

Breathes

-

Drops condensation

-

Experiences thermal shock

On R-410A, the shift was small.

On R-32, it's larger.

This is where 90% of installers lose perfect coil pitch — because they never check again after the first run.

This is why I do the wet set.

💧 6. The Wet Set — Tony’s Real Alignment Once Refrigerant Starts Flowing

Once the system is:

-

Brazed

-

Leak-tested

-

Vacuumed

-

Charged

Then you run the system for 15–20 minutes.

This is where the coil shows its true shape.

And this is where I re-set it for the second — and final — time.

▶️ Tony’s 10-Step Wet Set Method

1. Remove the front coil panel carefully

Don’t jostle the cabinet.

2. Inspect the frost pattern (the truth detector)

You want:

-

Even frost

-

No patchy spots

-

No diagonal banding

-

No top-heavy frost

-

No uneven sweating

Uneven frost = coil not centered.

3. Check pan drainage under active condensation

The water should:

-

Hit the middle

-

Travel down both sides evenly

-

Flow to the drain corner cleanly

If water tracks the wrong way?

You need to reset.

4. Recheck cabinet daylight with thermal influence

The upper rails shift slightly once warm.

5. Adjust coil tilt by shimming as needed

If I need 1/16″ of shift?

I do it now — not later.

6. Confirm TXV superheat after stabilization

If superheat is bouncing around?

The bulb might be tilted slightly due to coil expansion.

7. Final tighten the coil screws

Now — and only now — is the time to lock it in.

8. Seal the cabinet

Tape the top, sides, and seams only after the coil is permanently seated.

9. Re-run system for 5 minutes

Look for panel rattles or suction whistling.

10. Verify drain pan flow one last time

If the pan doesn’t drain smooth now, it never will.

🔍 7. The Top 5 Rookie Mistakes Tony Sees on Vertical Coil Installs

❌ Mistake #1: Setting the coil flush with the front panel

A coil should sit slightly back — not flush.

❌ Mistake #2: No-checking pan slope**

Most drainage failures aren’t clogs — they’re bad angles.

❌ Mistake #3: Never rechecking after thermal expansion

This is the real reason coils “mysteriously” leak.

❌ Mistake #4: Overscrewing the front panel

It warps the cabinet.

❌ Mistake #5: Adding mastic before the coil is truly final

If the coil shifts underneath sealed mastic, you trap the problem.

📘 8. Verified External Technical Resources

Here are reputable, verified external resources supporting coil installation, condensate management, and TXV behavior:

-

ASHRAE Fundamentals – Coil Construction & Airflow (Technical)

https://www.ashrae.org/technical-resources/ashrae-handbook -

HVAC Drainage Code Requirements (ICC)

https://codes.iccsafe.org/ -

EPA HVAC Moisture & Condensate Guidelines

https://www.epa.gov/mold -

AHRI Air Coil Performance Standards

https://www.ahrinet.org/standards -

RSES TXV Installation & Superheat Guidelines

https://www.rses.org -

Goodman (Daikin) Coil & TXV Transition Resources

https://www.daikincomfort.com/

🧱 9. Why Setting a Coil Twice Solves 90% of Install Problems Before They Exist

When homeowners complain about:

-

Water dripping

-

Cabinet sweating

-

Uneven cooling

-

Strange hissing

-

Loud airflow

-

High superheat

-

Low capacity

-

“One room isn’t cooling”

… the coil is the first place I look.

And in the last 30 years installing heat pumps, gas furnaces, and now R-32 systems, this truth has never changed:

A coil that isn’t set twice was never set correctly.

The CAPTA6030D3 coil is engineered beautifully — but it expects the installer to respect:

-

Geometry

-

Pitch

-

Expansion

-

TXV physics

-

Drain dynamics

And that’s why I set it twice.

Because the first set is for the installer.

The second set is for the system.

And only when both agree does the coil deserve its screws.

Buy this on Amazon at: https://amzn.to/47z1067

In the next topic we will know more about: Why a 120k Furnace Can’t Share a Return With a 3-Ton System — Tony’s Static Pressure Reality Check