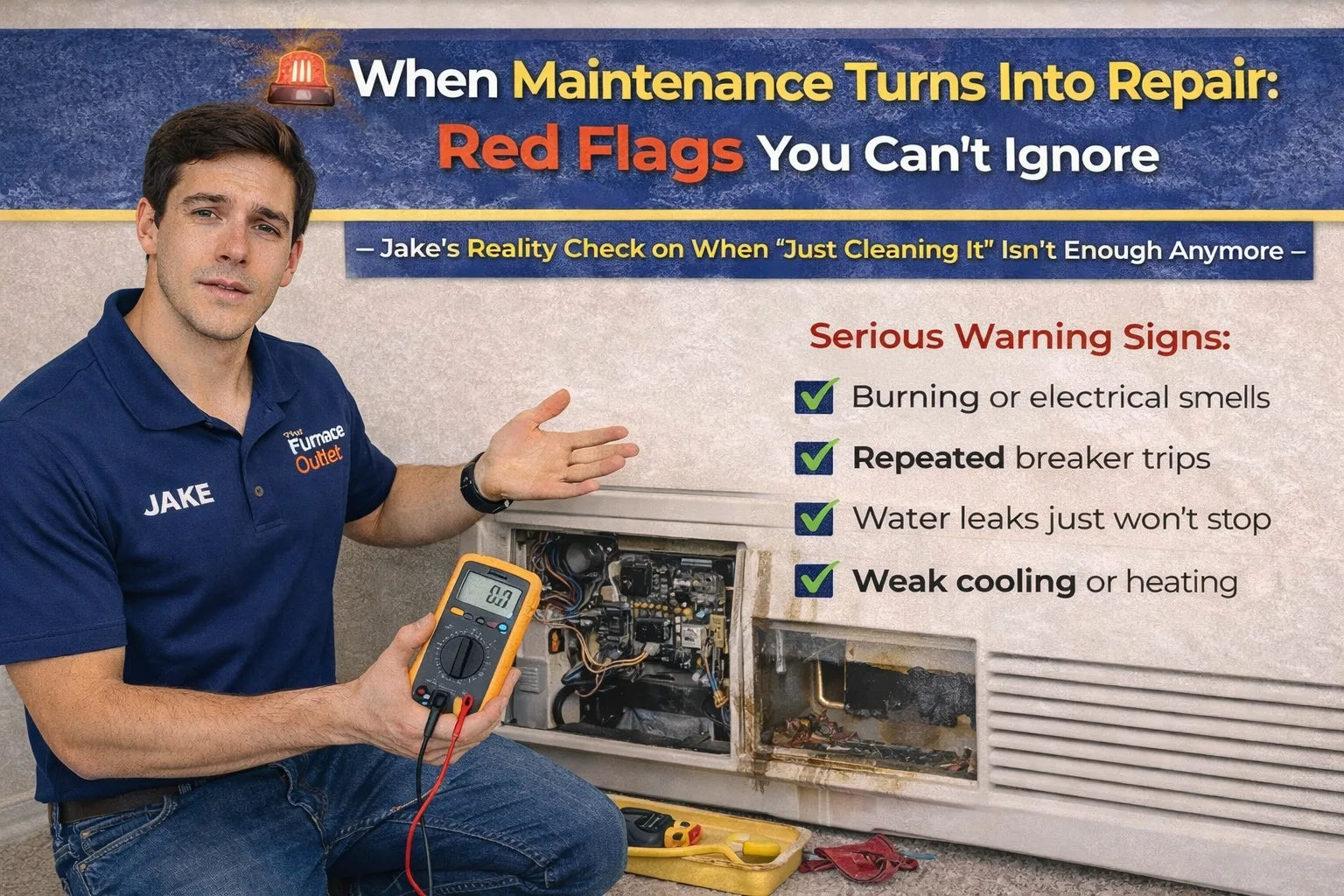

(Jake’s Reality Check on When “Just Cleaning It” Isn’t Enough Anymore)

Maintenance keeps a PTAC healthy.

Ignoring red flags breaks it.

I’ve walked into plenty of homes where the owner says,

“It just needed a cleaning.”

And sometimes that’s true.

But sometimes—maintenance has already missed its window, and the unit is quietly asking for repair, not another wipe-down.

This guide is about knowing when routine maintenance stops being the solution, and when continuing to “just run it” actually causes more damage.

We’ll use the Amana Distinctions 12,000 BTU PTAC with 3.5 kW electric heat as the reference point, but these warning signs apply to nearly all PTAC systems.

🔍 Maintenance vs. Repair: The Line Most People Miss

Here’s the difference in plain terms:

-

Maintenance = cleaning, inspecting, preventing

-

Repair = fixing damage that already exists

The problem?

Most PTACs don’t fail suddenly. They cross the line quietly—and by the time the failure is obvious, repair costs are higher.

Your job as an owner is to recognize when the unit is no longer asking for maintenance—it’s warning you.

🔥 Red Flag #1: Persistent Burning Smell (Not Just Dust)

What People Often Assume

“Just dust burning off.”

When That’s Normal

-

First heat cycle of the season

-

Fades within a few minutes

-

No breaker trips

-

No smoke

When It’s a Repair Red Flag

🚨 Smell continues after multiple cycles

🚨 Smell gets stronger over time

🚨 Accompanied by heat shutting off

🚨 Electrical buzzing or clicking

What This Usually Means

-

Overheated heat strips

-

Failing electrical connections

-

Damaged insulation

-

Heat strips pulling unsafe current

👉 At this point, cleaning is no longer enough.

⚡ Red Flag #2: Breaker Trips That Keep Coming Back

What Maintenance Can Fix

-

Dirty filters

-

Airflow restrictions

-

Minor overheating

What Maintenance Can NOT Fix

🚨 Breaker trips under normal operation

🚨 Breaker trips only in heating mode

🚨 Breaker trips immediately on startup

Likely Repair Causes

-

Loose or damaged wiring

-

Failing heat strip elements

-

Internal electrical shorts

-

Moisture-damaged components

Resetting the breaker repeatedly does not solve the problem—it hides it until damage spreads.

❄️ Red Flag #3: Icing or Frost That Returns After Cleaning

What Maintenance Fixes

-

Dirty filters

-

Mild airflow restriction

-

Light coil contamination

When It’s a Repair Signal

🚨 Ice returns within hours or days

🚨 Coil freezes solid

🚨 Unit runs constantly but doesn’t cool

Likely Causes

-

Refrigerant issues

-

Failing sensors

-

Compressor stress

-

Long-term airflow damage

At this stage, coil cleaning won’t fix the root problem.

💧 Red Flag #4: Repeated or Worsening Water Leaks

What Maintenance Handles

-

Clogged drains

-

Dirty drain pans

-

Minor tilt issues

When It’s Beyond Maintenance

🚨 Leaks return after drain cleaning

🚨 Rust forming inside the cabinet

🚨 Water reaching electrical sections

🚨 Musty smells that won’t go away

What This Usually Means

-

Corroded drain pan

-

Sleeve or cabinet damage

-

Long-term moisture exposure

-

Electrical risk increasing

Water problems that persist are repair problems, not cleaning problems.

🔊 Red Flag #5: New or Growing Electrical Noises

Sounds That Deserve Attention

🚨 Buzzing near the electrical compartment

🚨 Clicking that repeats rapidly

🚨 Humming that gets louder over time

What These Sounds Often Mean

-

Overloaded relays

-

Loose electrical terminals

-

Failing control boards

-

Heat strip electrical stress

If the sound is new, something has changed electrically—and maintenance alone won’t reverse that.

🌬️ Red Flag #6: Airflow That Never Fully Recovers

Maintenance Fixes

-

Dirty filters

-

Dusty blower wheels

-

Light debris

Repair-Level Symptoms

🚨 Airflow stays weak after cleaning

🚨 Blower sounds strained

🚨 Unit overheats quickly

Likely Causes

-

Worn blower motor

-

Damaged blower wheel

-

Electrical motor issues

Running with weak airflow accelerates heat strip and electrical failure.

🧠 Red Flag #7: Multiple Symptoms at Once

This is the big one.

If you notice:

-

Weak cooling and noise

-

Heat problems and breaker trips

-

Leaks and electrical smells

That’s not coincidence—that’s system stress.

Multiple symptoms usually mean:

-

Damage has spread

-

Components are affecting each other

-

Continued operation risks full failure

🛑 The “Don’t Push It” Rule

Here’s my rule from the field:

If a PTAC is warning you repeatedly, it’s not being dramatic—it’s being honest.

Running a unit through red flags leads to:

-

Higher repair costs

-

Electrical hazards

-

Full unit replacement sooner than necessary

🔧 When to Stop DIY Maintenance Immediately

Stop and call for professional service if you see:

-

Burnt wiring or connectors

-

Melted insulation

-

Refrigerant oil residue

-

Persistent breaker trips

-

Control board damage

-

Water inside electrical sections

No amount of cleaning fixes those.

📅 Why Early Repairs Save Money

A loose connection fixed early = small repair

A loose connection ignored = burnt board

A minor leak addressed early = drain repair

A leak ignored = cabinet corrosion

Maintenance prevents repairs—but repairs prevent replacements.

🧠 Jake’s Field Advice (Read This Twice)

✔ Maintenance keeps systems efficient

✔ Repairs keep systems safe

✔ Ignoring red flags costs more than fixing them

✔ Electrical problems rarely fix themselves

✔ PTACs give warnings—if you listen

🏁 Final Thoughts

Maintenance is powerful—but it has limits.

If your Amana Distinctions 12,000 BTU PTAC with 3.5 kW electric heat is showing any of these red flags, it’s telling you something important:

“I need attention beyond cleaning.”

Knowing when maintenance turns into repair isn’t pessimistic—it’s smart ownership.

Buy this on Amazon at: https://amzn.to/3WuhnM7

In the next topic we will know more about: Cooling & Heating Efficiency Optimization Through Maintenance