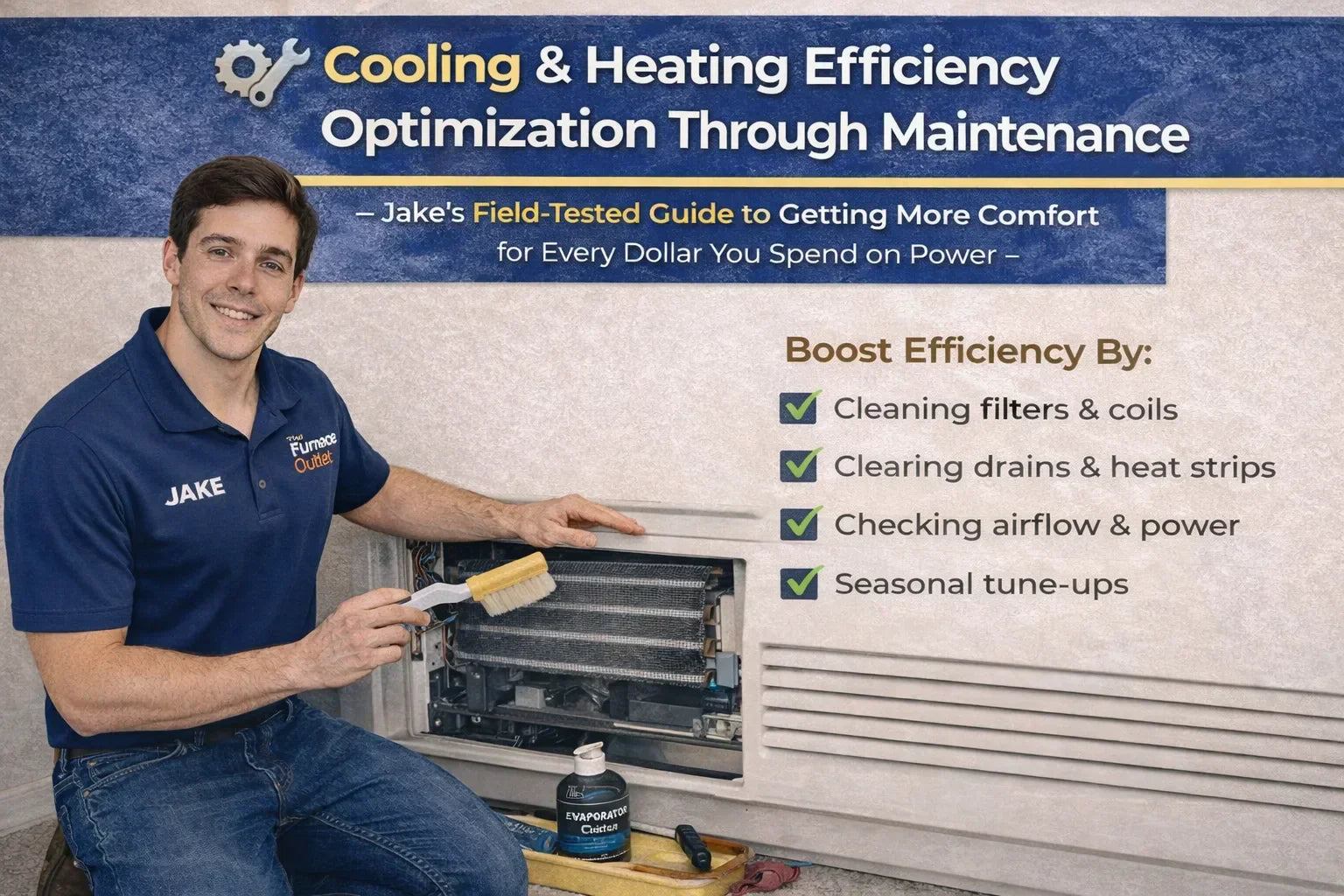

(Jake’s Field-Tested Guide to Getting More Comfort for Every Dollar You Spend on Power)

Most people think PTAC efficiency is locked in at the factory.

It’s not.

I’ve seen the same exact PTAC model use wildly different amounts of electricity in two identical rooms—purely because of maintenance habits. No fancy controls. No upgrades. Just basic care done right.

This guide explains how maintenance directly improves both cooling and heating efficiency, using the Amana Distinctions 12,000 BTU PTAC with 3.5 kW electric heat as the reference point.

If your PTAC feels slow, expensive to run, or inconsistent, this is where the efficiency is being lost—and how to get it back.

🔍 What “Efficiency” Really Means in a PTAC

Efficiency isn’t just a rating on a label.

In real life, PTAC efficiency means:

-

How fast the room reaches set temperature

-

How long the unit has to run to stay there

-

How much electrical stress the system sees doing it

Poor efficiency shows up as:

-

Longer run times

-

Higher utility bills

-

Uneven comfort

-

Faster component wear

Maintenance directly affects all of that.

🌬️ The Airflow Rule: Efficiency Starts With Movement

Every PTAC is an airflow machine.

If air doesn’t move freely:

-

Cooling capacity drops

-

Heat strips overheat

-

Electrical load increases

-

Runtime extends

The #1 Efficiency Killer

🚨 Dirty or restricted airflow

That includes:

-

Filters

-

Coils

-

Blower wheels

-

Blocked louvers

No airflow = wasted energy.

🪟 Step 1: Filter Maintenance (Highest ROI Efficiency Task)

If I had to pick one efficiency task, it’s filter care.

How Filters Affect Efficiency

-

Clean filter = correct airflow

-

Dirty filter = higher motor load + longer cycles

Optimization Tips

✔ Clean or replace filters regularly

✔ Don’t “stretch” filter intervals

✔ Use correct filter type (not over-restrictive)

A clogged filter can increase runtime 20–30% easily.

❄️ Step 2: Coil Cleanliness = Heat Transfer Efficiency

PTACs don’t cool or heat air—they move heat.

That happens at the coils.

Dirty Coils Cause

-

Poor heat absorption (cooling)

-

Poor heat rejection (outdoor side)

-

Longer run cycles

-

Higher electrical consumption

Efficiency Gain

Clean coils restore:

-

Faster temperature changes

-

Shorter cycle lengths

-

Lower compressor stress

Even light coil contamination costs efficiency.

💧 Step 3: Drain System Health & Hidden Efficiency Loss

Most people think drains only matter for leaks.

They also affect efficiency.

Why

-

Standing water increases humidity load

-

Wet coils don’t transfer heat efficiently

-

Mold growth restricts airflow

Optimization Steps

✔ Clean drain pan annually

✔ Flush drain path before cooling season

✔ Ensure proper unit tilt

A dry system runs more efficiently than a wet one.

🔥 Step 4: Heat Strip Cleanliness & Heating Efficiency

Electric heat strips are simple—but unforgiving.

Dirty Heat Strips Cause

-

Uneven heating

-

Overheating shutoffs

-

Electrical inefficiency

-

Burnt smells

Efficiency Optimization

✔ Clean heat strips before winter

✔ Ensure unrestricted airflow

✔ Keep filters spotless during heating season

When heat strips overheat, they cycle off—wasting energy and comfort.

⚡ Step 5: Electrical Health & Power Efficiency

Electrical inefficiency doesn’t show up as “poor heat.”

It shows up as:

-

Breaker trips

-

Voltage drop

-

Excessive heat

-

Short cycling

Maintenance That Improves Efficiency

✔ Tight, clean electrical connections

✔ No corrosion or moisture

✔ Proper airflow to reduce electrical stress

Loose or overheated connections waste energy as heat.

🌡️ Step 6: Thermostat & Control Optimization (Maintenance-Based)

You don’t need smart controls to gain efficiency.

Simple Maintenance Wins

✔ Clean temperature sensors

✔ Keep airflow steady near the sensor

✔ Avoid short cycling through airflow restriction

A sensor reading wrong by a few degrees causes unnecessary runtime.

🔄 Step 7: Seasonal Maintenance = Seasonal Efficiency

Efficiency losses are seasonal.

Cooling Season Efficiency Focus

-

Filters

-

Coils

-

Drain system

-

Outdoor airflow

Heating Season Efficiency Focus

-

Filters

-

Heat strips

-

Electrical connections

-

Blower performance

Skipping seasonal prep guarantees seasonal inefficiency.

📉 Where Efficiency Is Commonly Lost (Real World)

Here’s where I see efficiency disappear most often:

| Area | Result |

|---|---|

| Dirty filters | Long runtime |

| Dusty coils | Weak cooling |

| Blocked drains | Higher humidity |

| Dirty heat strips | Cycling heat |

| Poor airflow | Electrical stress |

None of these require replacement—only maintenance.

🧠 Jake’s Efficiency Rules From the Field

✔ Clean airflow beats higher settings

✔ Faster temperature change = higher efficiency

✔ Long run times mean lost efficiency

✔ Maintenance reduces electrical load

✔ Efficiency problems usually start small

Most PTACs don’t need upgrades—they need attention.

📅 Maintenance Schedule for Maximum Efficiency

| Task | Frequency |

|---|---|

| Filter cleaning | Monthly |

| Coil inspection | Annually |

| Drain cleaning | Annually |

| Heat strip cleaning | Before winter |

| Electrical visual check | Annually |

| Seasonal transition checks | Spring & Fall |

Efficiency comes from consistency, not complexity.

Buy this on Amazon at: https://amzn.to/3WuhnM7

In the next topic we will know more about: The Ultimate Annual PTAC Maintenance Checklist for Amana Distinctions Owners

🏁 Final Thoughts

Efficiency isn’t a feature—it’s a condition.

If you want your Amana Distinctions 12,000 BTU PTAC with 3.5 kW electric heat to cool faster, heat more evenly, and cost less to run, maintenance is the lever that moves everything.

Clean systems work less to do the same job—and that’s real efficiency.

-

🔗 https://www.energy.gov/energysaver/air-conditioner-maintenance

-

🔗 https://www.ptacs.com/changing-and-cleaning-the-filter-in-a-dm-or-dhpc-unit/