If there’s one PTAC maintenance task that gets owners into trouble, it’s coil cleaning.

I’ve seen it all:

-

Bent fins from stiff brushes

-

Corroded coils from harsh cleaners

-

Leaks caused by pressure washing

-

Units ruined by “deep cleans” they didn’t need

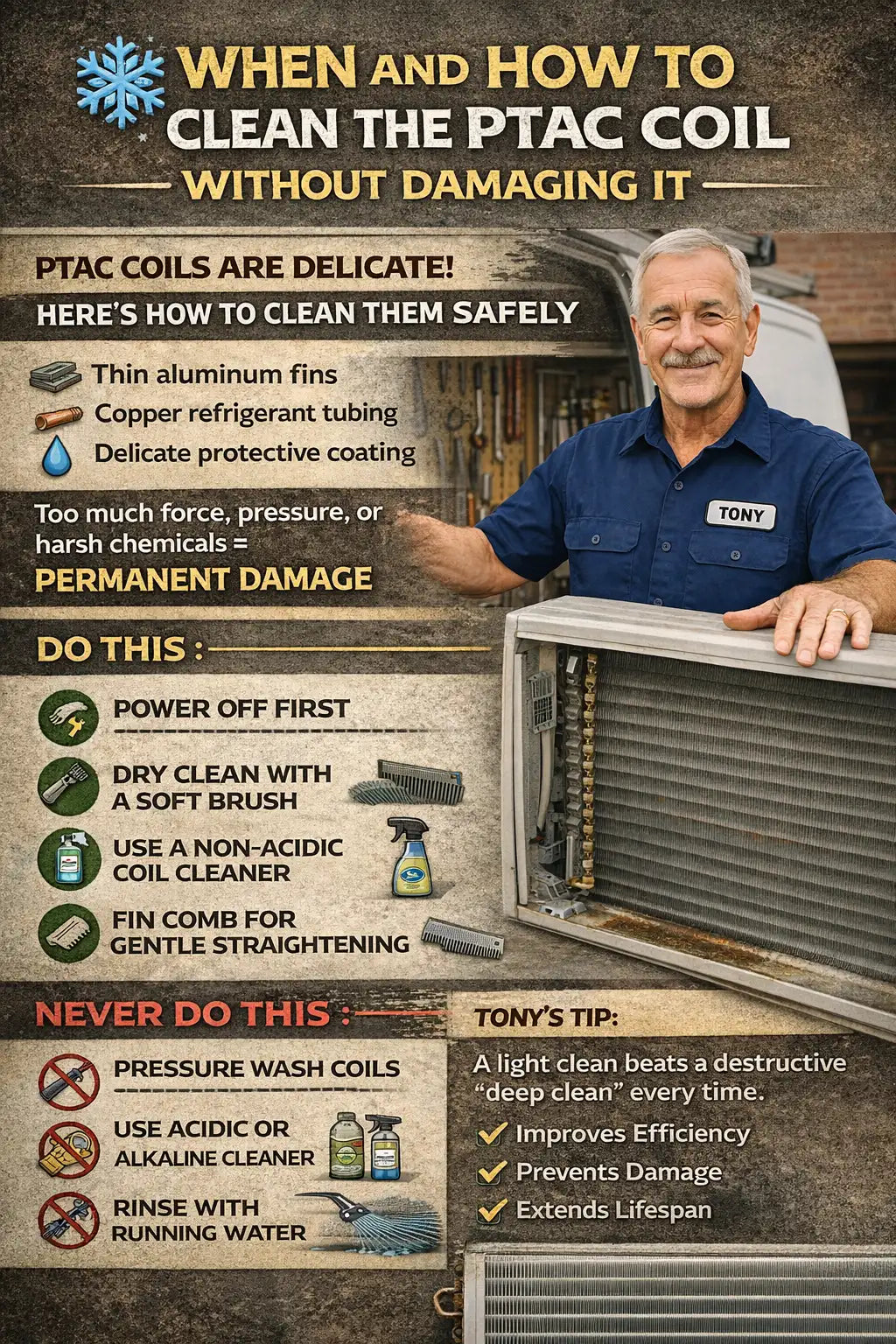

Here’s the truth most guides won’t tell you:

PTAC coils are effective because they’re delicate. Treat them like heavy machinery, and you’ll shorten their life fast.

This guide shows you when coil cleaning is actually needed, how to do it safely, and what mistakes cost owners the most.

Amana J-Series PTAC Model 17,000 BTU PTAC Unit with 5 kW Electric Heat

No scare tactics. No overkill. Just the right approach.

🧠 What the PTAC Coil Actually Does (And Why It’s Easy to Damage)

PTAC coils handle:

-

Heat exchange (cooling & heating modes)

-

Moisture removal

-

Airflow resistance control

They’re made of thin aluminum fins bonded to copper tubing. That design maximizes surface area — but it also means:

-

Fins bend easily

-

Tubing doesn’t tolerate pressure

-

Coatings can be stripped by chemicals

Understanding this is the first step to cleaning safely.

⏰ When a PTAC Coil Really Needs Cleaning

Not every coil needs frequent cleaning. Overcleaning causes more harm than light dust.

✅ Clean the Coil If You Notice:

-

Reduced cooling or heating performance

-

Longer run times

-

Ice forming during cooling

-

Visible dust buildup on fins

-

Musty or dirty airflow smell

❌ Don’t Clean the Coil If:

-

It looks clean and airflow is strong

-

Performance hasn’t changed

-

You cleaned it recently

Tony’s rule:

If airflow and performance are good, leave the coil alone.

ASHRAE confirms coil cleanliness matters — but unnecessary cleaning accelerates wear

https://www.ashrae.org/technical-resources

📅 How Often Should PTAC Coils Be Cleaned?

For most owners:

-

Residential use: Once per year

-

Hotels / rentals: Every 6–9 months

-

Dusty or coastal environments: Inspect twice a year

Inspection matters more than a fixed schedule.

🛑 Before You Start: What NOT to Do (Read This First)

Most PTAC coil damage comes from these mistakes:

🚫 Never Do This

-

Pressure wash the coil

-

Use acidic or alkaline cleaners

-

Scrub with wire or stiff brushes

-

Bend fins “back and forth”

-

Spray water directly into electrical areas

Once fins are crushed or corrosion starts, efficiency loss is permanent.

🔌 Step 0: Power Down & Access the Coil (5 Minutes)

What to Do

-

Turn off the unit

-

Unplug or shut off the breaker

-

Remove the front cover carefully

Always confirm the unit is fully powered down.

Why it matters:

Water + electricity + tight PTAC compartments = bad outcomes.

👀 Step 1: Inspect the Coil First (5 Minutes)

Before touching anything, look closely.

What You’re Checking For

-

Light dust vs heavy buildup

-

Grease residue

-

Matted lint

-

Bent fins

If buildup is light, you may only need a vacuum.

🧹 Step 2: Dry Cleaning (Safest First Option – 10 Minutes)

Dry cleaning solves most problems.

What to Use

-

Soft brush vacuum attachment

-

Handheld vacuum

-

Fin-safe brush (optional)

How to Do It

-

Work with the fin direction, not against it

-

Use light pressure

-

Let the vacuum do the work

This step alone restores airflow in many cases.

🧴 Step 3: Wet Cleaning (Only If Necessary – 15 Minutes)

If dry cleaning isn’t enough, proceed carefully.

What to Use

-

Non-acidic, non-corrosive coil cleaner

-

Spray bottle (not high pressure)

-

Soft cloth

How to Clean Safely

-

Lightly mist the coil — don’t soak it

-

Let cleaner dwell per instructions

-

Gently wipe loosened debris

-

Allow to air dry completely

What to Avoid

-

Foaming cleaners meant for large condensers

-

Rinsing with running water

-

Spraying toward control boards

ENERGY STAR emphasizes proper cleaning methods to preserve HVAC efficiency

https://www.energystar.gov/newhomes/features-benefits/heating-cooling

🧊 Step 4: Fin Care (Only If Needed)

Bent fins restrict airflow more than dirt.

Safe Fin Guidelines

-

Use a fin comb matched to fin spacing

-

Straighten once — don’t repeatedly bend

-

Skip badly crushed sections (don’t force them)

If more than 20–30% of fins are damaged, replacement is often more cost-effective.

💧 Step 5: Check Moisture & Drainage After Cleaning (5 Minutes)

Cleaning loosens moisture and debris.

After-Clean Check

-

No standing water in drain pan

-

No dripping into electrical areas

-

No cleaner residue left behind

CDC confirms moisture buildup increases mold risk

https://www.cdc.gov/mold-health/about/index.html

🔄 Step 6: Reassemble & Test Performance (10 Minutes)

Once dry:

-

Reinstall the front panel

-

Restore power

-

Test cooling or heating mode

What You Want to See

-

Faster temperature change

-

Stronger airflow

-

Smoother operation

EPA notes clean coils improve indoor air quality and system performance

https://www.epa.gov/indoor-air-quality-iaq

🛠️ Tools That Are Safe (And Worth Having)

You don’t need much — just the right things.

Recommended

-

Soft brush vacuum attachment

-

Non-acidic coil cleaner

-

Fin comb

-

Microfiber cloth

Not Recommended

-

Pressure sprayers

-

Degreasers

-

Acid-based cleaners

🚨 When to Stop and Call a Pro

DIY coil cleaning has limits.

Call a technician if you see:

-

Oily residue (possible refrigerant leak)

-

Heavy corrosion

-

Severe fin collapse

-

Electrical damage near the coil

The U.S. Department of Energy stresses professional service for refrigerant and sealed system issues

https://www.energy.gov/energysaver/energy-saver

🧠 Tony’s Final Advice on Coil Cleaning

Here’s what decades in the field have taught me:

Most PTAC coils don’t fail from dirt — they fail from aggressive cleaning.

Inspect first. Clean gently. Stop early.

A careful light clean beats a destructive “deep clean” every time.

If you respect the coil, it will return the favor with:

-

Better efficiency

-

Lower energy bills

-

Longer system life

That’s smart maintenance — not guesswork.

Buy this on Amazon at: https://amzn.to/434DIng

In the next topic we will know more about: Beyond the Filter: How to Improve Indoor Air Quality With Your PTAC