If you own a PTAC unit, here’s some good news:

You don’t need to be an HVAC tech to keep it running efficiently.

And here’s the honest part: You do need a system.

Most PTAC problems I get called out for — weak airflow, poor cooling, noisy operation, burned-out heat strips — could’ve been avoided with a simple DIY tune-up done once or twice a year.

Amana J-Series PTAC Model 17,000 BTU PTAC Unit with 5 kW Electric Heat

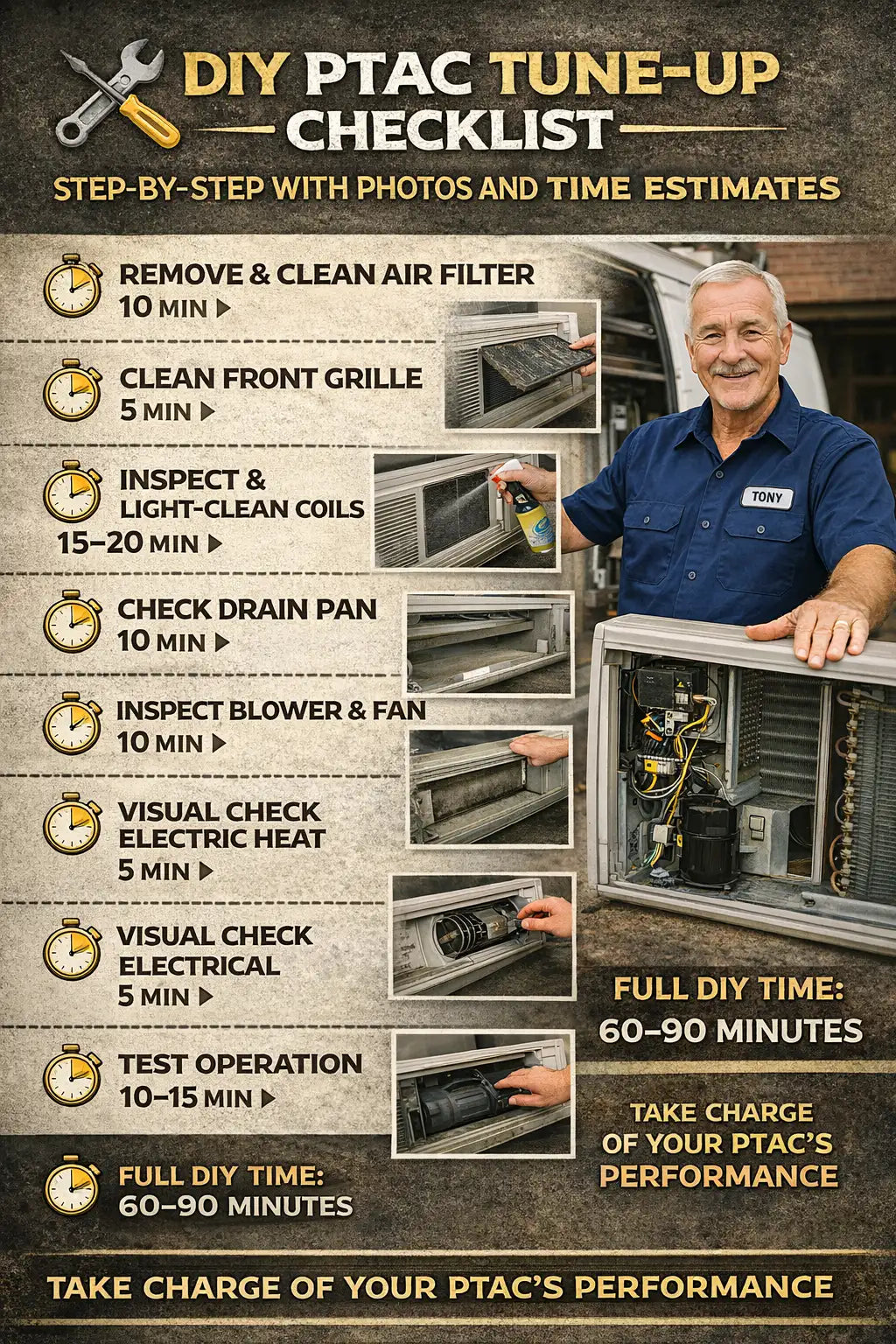

This guide walks you through a complete DIY PTAC tune-up, step by step, with:

-

Clear instructions

-

Realistic time estimates

-

Photo checkpoints (so you know what “normal” looks like)

-

Safety boundaries (what not to touch)

No guesswork. No unnecessary steps. Just what works.

⏱️ Total Time & Skill Level (Set Expectations First)

Total Time: 60–90 minutes

Skill Level: Beginner to Intermediate

Tools Needed: Basic household tools

Best Time to Do This: Spring or Fall (before peak demand)

If you can use a screwdriver and clean carefully, you can do this.

🔌 Step 0: Power Down & Safety Check (5 Minutes)

Before you touch anything, cut power.

What to Do

-

Turn the PTAC off at the controls

-

Unplug the unit or shut off the breaker

-

Confirm the display is completely off

Why This Matters

PTACs combine electrical components, moving parts, and moisture. Powering down isn’t optional — it’s non-negotiable.

🧽 Step 1: Remove & Clean the Air Filter (10 Minutes)

This is the most important step — and the most skipped.

What to Do

-

Remove the front grille

-

Slide out the filter

-

Wash with warm water and mild soap (if reusable)

-

Let it fully air-dry

What to Look For

-

Gray or black dust buildup

-

Matted lint

-

Grease residue (common in kitchens)

A clogged filter restricts airflow, which causes:

-

Poor cooling

-

Overheating electric heat

-

Higher energy use

ENERGY STAR confirms dirty filters significantly reduce HVAC efficiency

https://www.energystar.gov/newhomes/features-benefits/heating-cooling

🧹 Step 2: Clean the Front Grille & Air Intake (5 Minutes)

Dust doesn’t stop at the filter.

What to Do

-

Wipe grille and louvers with a damp cloth

-

Vacuum vent openings

-

Remove pet hair or debris

Blocked intakes undo all your filter work.

❄️ Step 3: Inspect & Light-Clean the Coils (15–20 Minutes)

Coils are where efficiency is won or lost.

What to Do

-

Gently vacuum visible dust using a soft brush

-

Use non-acidic coil cleaner if buildup is visible

-

Never bend fins or scrape metal

What NOT to Do

-

No pressure washers

-

No acidic cleaners

-

No hard brushes

ASHRAE identifies coil cleanliness as a major efficiency factor

https://www.ashrae.org/technical-resources

💧 Step 4: Check the Drain Pan & Condensate Path (10 Minutes)

Moisture is part of cooling — standing water is not.

What to Do

-

Inspect the drain pan for water or slime

-

Wipe pan clean

-

Make sure drain openings are clear

Red Flags

-

Musty odors

-

Visible algae

-

Water pooling inside the unit

CDC guidance confirms stagnant moisture promotes mold growth

https://www.cdc.gov/mold-health/about/index.html

🌬️ Step 5: Inspect the Blower & Fan Area (10 Minutes)

You’re not servicing motors — just checking cleanliness.

What to Do

-

Look for dust buildup on blower wheel

-

Remove loose debris

-

Spin blower gently by hand (power off)

What You’re Listening For

-

Grinding

-

Resistance

-

Imbalance

If it doesn’t spin freely, stop and call a pro.

🔥 Step 6: Electric Heat Visual Check (5 Minutes)

If your PTAC uses electric heat, airflow matters even more.

What to Do

-

Visually inspect heat area for dust buildup

-

Make sure nothing blocks airflow

-

Do not touch heating elements

Restricted airflow + electric heat = overheating risk.

The U.S. Department of Energy stresses airflow importance for electric heating safety

https://www.energy.gov/energysaver/energy-saver

🔌 Step 7: Electrical Visual Inspection (5 Minutes)

You’re looking — not repairing.

What to Look For

-

Loose wires

-

Burn marks

-

Melted insulation

-

Strong electrical smells

If you see any of these, stop. That’s professional territory.

🔄 Step 8: Reassemble & Restore Power (5 Minutes)

What to Do

-

Reinstall filter (fully dry)

-

Secure front panel

-

Restore power

Double-check everything is seated correctly before powering up.

▶️ Step 9: Test Operation (10–15 Minutes)

This confirms your work paid off.

Cooling Test

-

Set to cool mode

-

Confirm cold air within minutes

-

Listen for smooth operation

Heating Test (If Applicable)

-

Switch to heat mode

-

Verify warm air quickly

-

Confirm fan starts immediately

EPA notes airflow and cleanliness directly affect indoor air quality

https://www.epa.gov/indoor-air-quality-iaq

🗂️ DIY Tune-Up Summary Checklist (Quick Reference)

✅ Power off safely

✅ Clean or replace filter

✅ Clean front grille

✅ Light-clean coils

✅ Inspect drain pan

✅ Check blower area

✅ Visual heat & electrical inspection

✅ Test cooling & heating

🛡️ What This DIY Tune-Up Does (And Doesn’t)

What It Does

-

Improves efficiency

-

Reduces noise

-

Extends lifespan

-

Lowers energy bills

What It Doesn’t Do

-

Replace refrigerant

-

Repair electronics

-

Fix mechanical failures

Those require licensed service — and that’s okay.

🧠 Tony’s Final Advice

Here’s the truth I’ve learned over decades:

PTACs don’t need perfection — they need consistency.

One careful DIY tune-up twice a year beats emergency service calls every time.

If you can clean, inspect, and pay attention, your PTAC will reward you with quiet, reliable comfort.

That’s a fair trade.

Buy this on Amazon at: https://amzn.to/434DIng

In the next topic we will know more about: When and How to Clean the PTAC Coil Without Damaging It