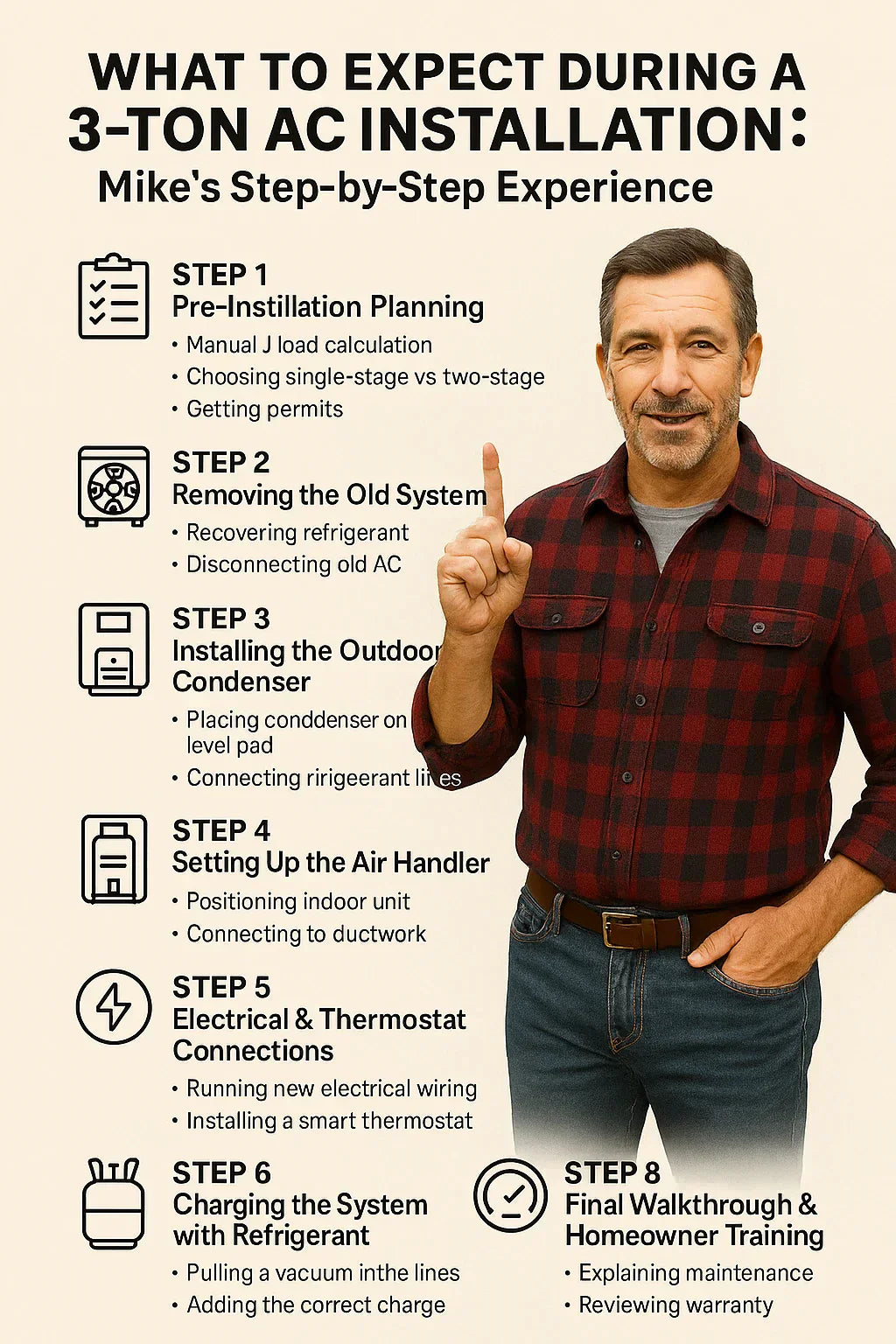

📌 Introduction: Why Knowing the Process Matters

When I was preparing to replace my old AC system, I’ll admit — I didn’t know what to expect. I figured it was a matter of swapping out a box outside and connecting it to my ducts. Turns out, a 3-ton AC installation is a full-day project with several moving parts, from permits and duct inspections to refrigerant charging and final walkthroughs.

The good news? When you know the process, you can budget properly, plan your day, and make sure you’re getting a professional installation — not a rush job. In this guide, I’ll take you through my step-by-step experience installing a 3-ton AC system with an air handler in 2025.

🏠 Step 1: Pre-Installation Planning

Before any tools come out, planning is critical.

✅ Load Calculation (Manual J)

Your installer should perform a Manual J load calculation, which considers your home’s size, insulation, windows, and climate zone. Don’t rely on square footage alone — an oversized or undersized system can cost you in comfort and efficiency.

🔗 Energy.gov on Load Calculations

✅ Choosing Staging

-

Single-stage: Budget-friendly, runs full blast when cooling.

-

Two-stage: More consistent comfort, better humidity control.

-

I chose two-stage for steady comfort in my humid summer climate.

✅ Deciding on Refrigerant

-

R-410A: Still used, but phasing out due to high GWP.

-

R-32: Lower environmental impact, more efficient, future-proof.

-

I picked R‑32, knowing it’ll be the industry standard moving forward.

✅ Permits & Scheduling

Most cities require a permit for AC installation, ensuring the work meets safety and efficiency standards. My contractor handled this, but some homeowners need to apply separately.

Mike’s Tip: Always ask your installer to include permit costs in the quote to avoid surprise fees.

🔧 Step 2: Removing the Old System

The crew started by removing my old unit.

-

Refrigerant Recovery: Technicians used EPA-approved equipment to safely remove the old R-410A refrigerant. It’s illegal (and harmful) to vent it into the air.

-

Disconnecting: They shut off power at the breaker, disconnected the wiring, and carefully separated the old condenser from the line set.

-

Haul-Away: My contractor included hauling away the old system, which saved me time.

This step took about 1.5 hours.

⚙️ Step 3: Installing the Outdoor Condenser

The outdoor condenser is the most visible part of your AC.

-

Placement: Mine was set on a new composite pad to prevent sinking. It needed at least 18 inches of clearance on all sides for airflow.

-

Leveling: A perfectly level base prevents vibration and wear.

-

Connection: They connected the new R‑32-ready line set, sealed it, and insulated the suction line.

🔗 Carrier Residential AC Guide

🌀 Step 4: Setting Up the Air Handler

Inside, the air handler does the heavy lifting of moving air through the ducts.

-

Location: Mine went in the utility closet where the old unit sat.

-

Connections: They tied it into the existing ductwork. Because my ducts were in good shape, I didn’t need full replacement, but they sealed and insulated joints to improve efficiency.

-

Drain Line: A new PVC condensate line was installed with a safety float switch to shut down the unit if the drain clogged.

Mike’s Tip: Ask about duct inspection — leaky ducts can waste 20–30% of your cooling energy.

⚡ Step 5: Electrical & Thermostat Connections

The electricians handled the wiring.

-

Breaker: My system needed a dedicated 240-volt breaker.

-

Wiring: They ran new wires to the condenser and air handler, securing them to code.

-

Thermostat: Because I chose a two-stage system, I upgraded to a smart thermostat for better staging control.

🔗 Trane on Thermostat Compatibility

❄️ Step 6: Charging the System with Refrigerant

This step is vital for system performance.

-

Vacuum: They used a vacuum pump to remove air and moisture from the line set.

-

Charge: The system was then charged with the precise amount of R‑32. Too much or too little refrigerant can wreck efficiency.

-

Leak Test: Sensors confirmed no leaks.

Because R‑32 is mildly flammable (A2L), the techs followed all updated safety standards.

🧪 Step 7: Testing & Fine-Tuning

With the system installed and charged, it was time to test.

-

Airflow: Checked through each vent to confirm balanced distribution.

-

Temperature Split: Measured supply vs. return air to confirm proper cooling.

-

Thermostat Response: Ensured smooth switching between low and high stages.

-

Noise Check: Verified quiet operation in low stage.

This phase took about 1.5 hours.

📜 Step 8: Final Walkthrough & Homeowner Training

Finally, my installer sat down with me for a walkthrough.

-

Showed me how to replace filters

-

Explained warranty details (10 years on compressor)

-

Provided paperwork for rebates and my city’s permit closure

-

Walked me through seasonal maintenance tasks

🔗 ENERGY STAR: Central AC Rebates

Mike’s Tip: Record the model and serial numbers for your system. You’ll need these for warranty claims and rebate applications.

💰 Mike’s Real-World Timeline & Costs

-

Time Required: 8.5 hours (crew of 3)

-

Total Cost: ~$9,500 installed

-

Breakdown:

-

Equipment: ~$6,200

-

Labor: ~$3,000

-

Permit & fees: ~$300

-

With rebates, I expect to get back ~$600, bringing the net cost to $8,900.

✅ Mike’s Tips for a Smooth Installation

-

Get 3 Quotes: Prices can vary by thousands.

-

Insist on Manual J: Don’t let anyone size by square footage alone.

-

Ask About Refrigerant: R‑32 is the future — make sure your system is compatible.

-

Plan to Be Home: You’ll want to see the testing and learn the system.

-

Look for Rebates: Federal, state, and utility programs can save you hundreds.

📊 Quick Reference Timeline

| Step | Time (Approx.) |

|---|---|

| Planning & Permits | 1–2 weeks before |

| Removal of Old System | 1–2 hours |

| Outdoor Condenser Install | 2–3 hours |

| Air Handler Setup | 2–3 hours |

| Electrical & Thermostat Setup | 1–2 hours |

| Refrigerant Charging & Testing | 1–2 hours |

| Final Walkthrough | 30 minutes |

⚙️ Bottom Line: Installing a 3-ton AC system in 2025 is a full-day process that costs between $7,000 and $12,000, depending on efficiency, refrigerant, and installation complexity. With proper planning and a good contractor, you’ll enjoy reliable, efficient comfort for the next 15–20 years.

In the next topic we will read more about: How Efficient Are 3-Ton Systems? Understanding SEER2 and Real-World Savings