Let’s get one thing out of the way.

Skipping seasonal AC tune-ups doesn’t always break your system right away.

That’s why people keep skipping them.

But what it does do—quietly and consistently—is turn small, cheap problems into big, expensive ones. And by the time most homeowners feel it, the damage is already done.

This article lays out the real costs of skipping tune-ups: higher energy bills, shorter equipment life, surprise breakdowns, and warranty headaches. No fluff. Just the numbers—and the why behind them.

2.5 Ton Up To 15 SEER2 Goodman Air Conditioner Model - GLXS3BN3010

🧠 What a Seasonal Tune-Up Actually Covers (Quick Reality Check)

Before we talk costs, let’s define the baseline.

A proper seasonal tune-up typically includes:

-

Cleaning condenser coils

-

Checking airflow and filters

-

Inspecting electrical components

-

Verifying refrigerant performance (not “topping off”)

-

Tightening accessible connections

-

Checking startup/shutdown behavior

-

Spotting early wear

That’s it. No magic. No gimmicks.

According to the U.S. Department of Energy, regular maintenance keeps systems operating closer to their rated efficiency and reduces breakdowns.

https://www.energy.gov/energysaver/air-conditioner-maintenance

Tony Truth:

Tune-ups don’t make your AC better than new. They keep it from getting worse.

📈 Cost #1: Higher Energy Bills (The Silent Drain)

Dirty coils, restricted airflow, and loose electrical components all make your AC work harder to do the same job.

🔌 What That Looks Like in Real Life

-

Longer run times

-

Higher head pressure

-

More frequent cycling

-

Increased kWh usage

Even modest efficiency loss adds up.

ENERGY STAR notes that poorly maintained AC systems can use 10–30% more energy than necessary.

https://www.energystar.gov/saveathome/heating-cooling

💵 Annual Cost Impact (Typical Home)

-

10% increase on a $1,800 cooling bill = $180/year

-

20% increase = $360/year

-

Over 5 years = $900–$1,800 wasted

Tony Math:

You don’t see the bill spike all at once. You bleed money month by month.

🔥 Cost #2: Electrical Failures That Start Small

Most major AC repairs start as minor electrical issues:

-

Pitted contactors

-

Weak capacitors

-

Loose terminals

-

Heat-stressed wiring

Seasonal tune-ups catch these early.

💸 Typical Repair Costs (If Ignored)

| Component | Cost Range |

|---|---|

| Capacitor | $150–$300 |

| Contactor | $150–$400 |

| Control board | $500–$1,200 |

The Electrical Safety Foundation International emphasizes that early detection of electrical wear reduces failure and fire risk.

👉 https://www.esfi.org

Tony Truth:

Electrical problems don’t fix themselves. They wait for the hottest day of the year.

🧊 Cost #3: Refrigerant & Coil Problems That Snowball

Skipping tune-ups often means:

-

Dirty coils

-

Undetected airflow issues

-

Incorrect operating pressures

Those conditions can lead to:

-

Icing

-

Compressor stress

-

Oil return problems

The EPA makes it clear that refrigerant issues are often the result of other maintenance failures—not the cause.

👉 https://www.epa.gov/section608

💥 What Happens Next

-

Compressor runs hotter

-

Efficiency drops

-

Internal wear accelerates

And once a compressor is damaged, the bill gets serious.

💣 Cost #4: Compressor Damage (The Big One)

This is where skipping tune-ups really hurts.

💵 Real-World Costs

-

Compressor replacement: $2,000–$4,000+

-

Labor + refrigerant + downtime

-

Often not cost-effective on older systems

Many compressors fail not because they’re weak—but because maintenance was skipped for years.

Tony Math:

A $150 tune-up looks expensive—until it prevents a $3,000 repair.

⏳ Cost #5: Shortened System Lifespan

Most central AC systems are designed to last 12–15 years.

Without maintenance?

-

8–10 years is common

-

Sometimes less in harsh climates

That’s not a coincidence.

The Air Conditioning Contractors of America (ACCA) consistently identifies maintenance neglect as a top contributor to premature system replacement.

👉 https://www.acca.org

🧮 Replacement Timing Reality

Replacing a system 5 years early can cost:

-

$6,000–$12,000 sooner than planned

That’s not just a repair—that’s a financial setback.

🧾 Cost #6: Warranty Headaches

This one surprises a lot of homeowners.

Most manufacturers require documented maintenance for warranty coverage. If a major component fails and there’s no service history, claims can be:

-

Delayed

-

Reduced

-

Denied outright

Tony Truth:

Warranties protect maintained equipment—not neglected equipment.

⚙️ What This Means for Goodman AC Owners

Goodman systems are built to be:

-

Durable

-

Serviceable

-

Cost-effective

But they still depend on:

-

Clean coils

-

Stable electrical operation

-

Proper airflow

-

Correct refrigerant performance

If you’re running a unit like the Goodman 2.5-Ton 13.4 SEER2 R-32 condenser, skipping tune-ups risks:

-

Efficiency loss

-

Compressor stress

-

Shortened lifespan

-

Warranty complications

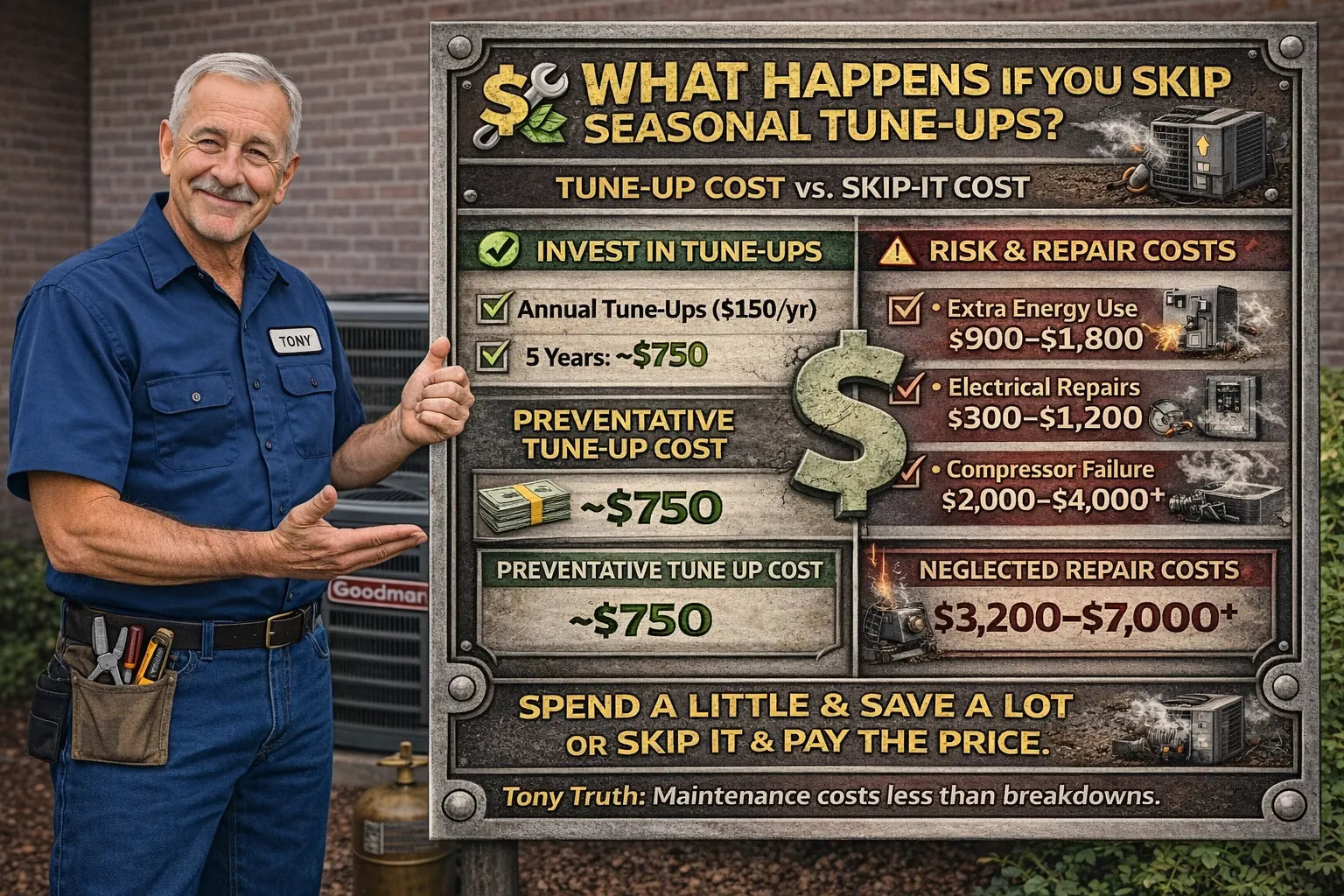

📊 Tune-Up Cost vs. Skip-It Cost (Side-by-Side)

| Scenario | 5-Year Cost |

|---|---|

| Annual tune-ups ($150/yr) | ~$750 |

| Extra energy use | $900–$1,800 |

| Electrical repairs | $300–$1,200 |

| Compressor risk | $2,000–$4,000 |

Skipping tune-ups isn’t saving money—it’s deferring a bigger bill.

🧠 Final Word from Tony

Seasonal tune-ups aren’t about perfection.

They’re about prevention.

You can skip them for a while—and many people do. But the system keeps score. And eventually, it collects.

If you want predictable costs, steady comfort, and a system that lasts:

-

Tune it up

-

Catch problems early

-

Pay small now instead of big later

That’s not sales talk.

That’s experience.

Buy this on Amazon at: https://amzn.to/47dm4yJ

In the next topic we will know more about: Maintenance for Longevity: How to Extend the Life of Your Goodman 2.5-Ton 13.4 SEER2 AC