Let me start with something important:

Most AC failures don’t start with refrigerant.

They start with electricity.

Loose connections, worn components, and ignored safety issues quietly build up until one hot afternoon your system doesn’t start—or worse, trips breakers or damages major parts.

2.5 Ton Up To 15 SEER2 Goodman Air Conditioner Model - GLXS3BN3010

The good news? You don’t need to be an electrician or HVAC tech to catch most problems early. You just need a quarterly routine that focuses on what’s safe to check and what’s smart to leave alone.

This guide shows you exactly that.

🛑 First Rule: Know What You Should NOT Touch

Before we talk about what to inspect, let’s be clear about boundaries.

🚫 Homeowners Should NOT:

-

Open sealed electrical compartments

-

Touch live wiring

-

Test capacitors

-

Measure voltage or amperage

-

Bypass safety switches

-

Handle refrigerant-related electrical components

Those steps require training, tools, and licensing.

Tony Truth:

Safety checks are about observation—not heroics.

If something looks wrong, the win is calling it out early, not fixing it yourself.

🧠 Why Quarterly Electrical Checks Matter

Electricity is the nervous system of your AC.

When problems develop, they usually start small:

-

Slightly loose terminals

-

Minor corrosion

-

Heat stress

-

Vibration wear

Left unchecked, they become:

-

Burned contactors

-

Failed capacitors

-

Short cycling

-

Tripped breakers

-

Compressor damage

The U.S. Department of Energy identifies electrical issues as a leading cause of AC breakdowns and efficiency loss:

https://www.energy.gov/energysaver/air-conditioner-maintenance

🗓️ Why Quarterly (Not Just Annually)?

Annual tune-ups are great—but electrical issues don’t wait a year.

Quarterly checks:

-

Catch seasonal wear early

-

Reduce summer failure risk

-

Improve safety

-

Cost nothing but time

Tony Rule:

Five minutes every three months beats a breakdown every summer.

🔌 Step 1: Inspect the Outdoor Disconnect Box

This is your AC’s first line of electrical safety.

✅ What to Look For

-

Disconnect firmly seated

-

No cracks in the enclosure

-

No rust streaks or water intrusion

-

No buzzing or heat smell

🚨 Red Flags

-

Melted plastic

-

Loose or crooked disconnect

-

Insects or nests inside

-

Moisture buildup

If you see damage here, stop and call a pro.

⚙️ Step 2: Listen During Startup and Shutdown

Your ears are powerful diagnostic tools.

👂 Listen For:

-

Clean, smooth startup

-

Fan and compressor engaging together

-

Normal shutdown without clunking

🚩 Warning Sounds

-

Loud buzzing

-

Rapid clicking

-

Delayed fan start

-

Hard stops

Those sounds often point to electrical wear—especially contactors and capacitors.

ENERGY STAR notes abnormal electrical sounds as an early indicator of system problems:

https://www.energystar.gov/saveathome/heating-cooling

🧯 Step 3: Check Breakers and Panel Labels

Your electrical panel tells a story.

🔍 What to Check

-

AC breaker not tripping

-

Correct breaker size

-

Clearly labeled circuit

-

No heat discoloration

🚫 What Not to Do

-

Don’t “upsize” a breaker

-

Don’t reset repeatedly

-

Don’t ignore warm breakers

Tony Warning:

A breaker that trips once is a warning.

A breaker that trips twice is a message.

🧼 Step 4: Inspect Visible Wiring & Conduit (Look, Don’t Touch)

You’re checking condition—not connections.

✅ Safe Visual Checks

-

Insulation intact

-

No exposed copper

-

No chew marks (rodents)

-

Conduit secured and not cracked

Rodent damage is more common than most homeowners realize—and it’s a serious fire risk.

The Electrical Safety Foundation International emphasizes routine visual inspections to prevent electrical hazards:

👉 https://www.esfi.org

🌧️ Step 5: Moisture & Corrosion Watch

Water and electricity don’t mix—and AC systems deal with both constantly.

🚨 Look For

-

Rust around panels

-

Corrosion on fasteners

-

Water pooling near electrical areas

-

Condensation dripping onto wiring

Moisture accelerates electrical failure faster than almost anything else.

🧲 Step 6: Check for Vibration & Mounting Issues

Electrical components don’t like movement.

🔩 Inspect:

-

Condenser sitting level

-

No rattling panels

-

Tight exterior screws

-

No shaking during operation

Vibration loosens terminals over time—and loose terminals create heat.

🔥 Step 7: Smell Test (Yes, Really)

Your nose can save your system.

🚨 Stop Immediately If You Smell:

-

Burning plastic

-

Electrical ozone

-

Metallic heat smell

Shut off power at the disconnect and call a professional.

The National Fire Protection Association (NFPA) warns that electrical odor is a key early indicator of fire risk:

👉 https://www.nfpa.org

⚠️ Step 8: Thermostat & Control Safety Check

Electrical safety isn’t just outside.

✔️ Check That:

-

Thermostat responds immediately

-

Screen doesn’t flicker

-

No error codes flashing

-

Wiring behind thermostat is secure (visual only)

Loose low-voltage wiring causes more nuisance shutdowns than most people realize.

⚙️ Safety Checks for Goodman AC Systems (What Matters Most)

Goodman systems are known for:

-

Straightforward electrical layouts

-

Serviceable designs

-

Strong component reliability

But they still rely on:

-

Stable power

-

Tight connections

-

Dry, protected electrical paths

If you’re running a system like the Goodman 2.5-Ton 13.4 SEER2 R-32 condenser, quarterly electrical checks protect:

-

Control boards

-

Contactors

-

Fan motors

-

Compressors

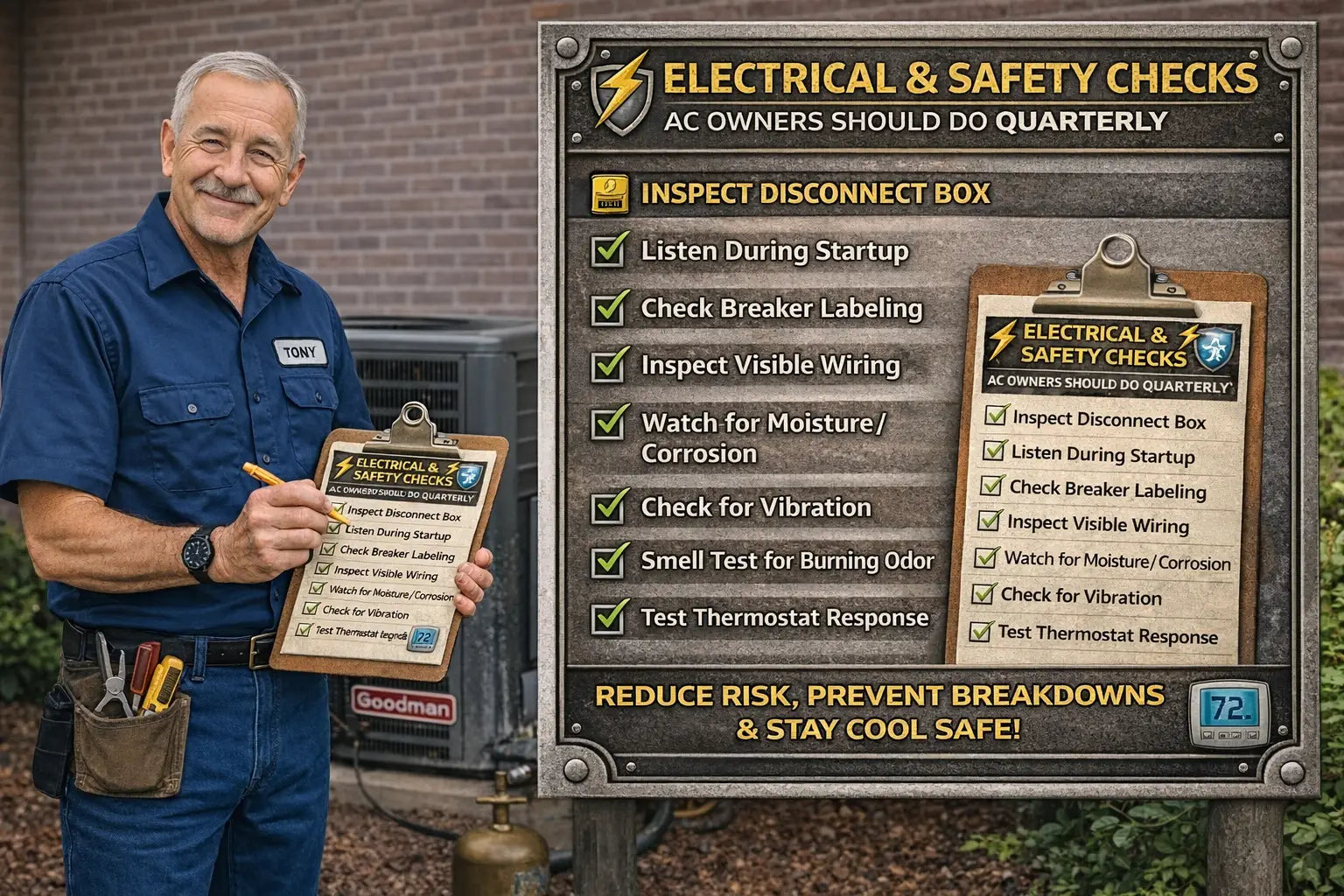

📋 Quarterly Electrical Safety Checklist (Quick Reference)

| Check | Do This |

|---|---|

| Disconnect | Inspect for damage |

| Sounds | Listen during startup |

| Breaker | Confirm stability |

| Wiring | Visual inspection only |

| Moisture | Look for corrosion |

| Vibration | Check mounting |

| Smells | Shut down if present |

| Thermostat | Confirm response |

Print it. Use it.

💸 What Ignoring Electrical Safety Really Costs

Let’s be honest about the numbers:

-

Burned contactor: $150–$400

-

Failed capacitor: $150–$300

-

Control board failure: $500–$1,200

-

Compressor damage: $2,000+

Tony Math:

Electrical problems don’t get cheaper with time.

They get louder—and more expensive.

🧠 Final Word from Tony

Electrical safety isn’t about fear.

It’s about awareness.

You don’t need meters, licenses, or tools to:

-

Listen

-

Look

-

Smell

-

Observe patterns

Do these checks quarterly, and you’ll:

-

Reduce breakdowns

-

Improve safety

-

Extend system life

-

Sleep better during heat waves

Buy this on Amazon at: https://amzn.to/47dm4yJ

In the next topic we will know more about: What Happens If You Skip Seasonal Tune-Ups? A Cost Breakdown