If you’ve ever wondered what actually happens when an HVAC technician shows up for an inspection or diagnosis, you’re not alone. Many homeowners picture a quick look at the furnace and a thumbs-up—or worse, a mysterious list of repairs without much explanation.

The truth is, a proper HVAC inspection is a detailed, step-by-step process designed to keep your heating and cooling system safe, efficient, and long-lasting. For systems nearing the end of their lifespan, inspections also help determine whether repair or replacement makes the most sense.

In this guide, I’ll break down what happens during an HVAC inspection, what tools technicians use, and how you can prepare for one.

Why HVAC Inspections Matter

Routine inspections do more than keep your system running—they protect your investment, prevent costly breakdowns, and maintain efficiency.

According to the U.S. Department of Energy, annual maintenance can improve efficiency by up to 10% and extend system life. That’s a small investment with big returns.

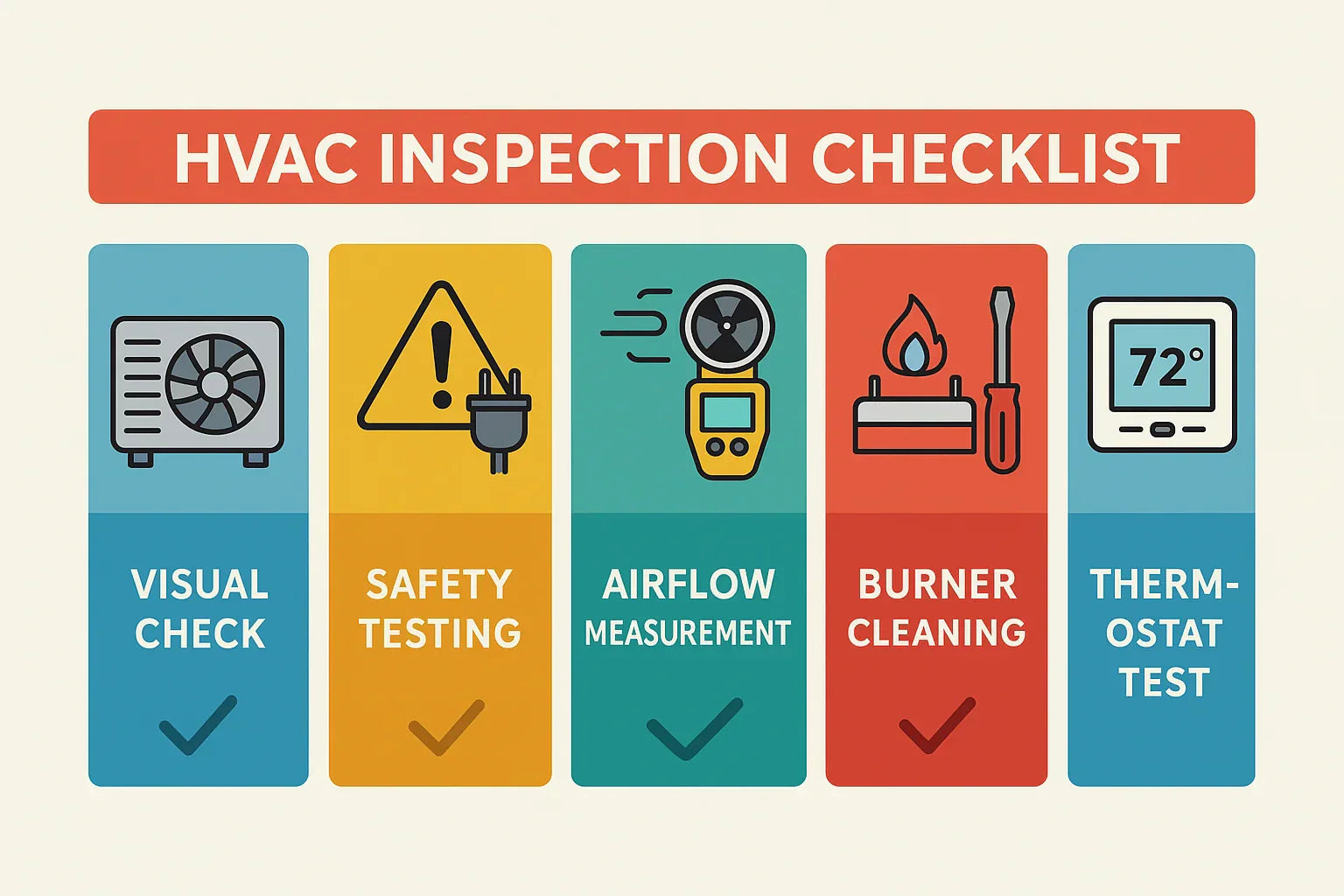

Step-by-Step Breakdown of an HVAC Inspection

A quality inspection isn’t just a “look and leave” job. Here’s what a thorough technician will typically do:

1. Initial Consultation and History Review

-

Discuss system performance, strange noises, uneven heating/cooling

-

Review past repairs and maintenance history

2. Visual Equipment Check

-

Inspect furnace, AC, or heat pump for damage, corrosion, or leaks

-

Verify proper ventilation and clearance

The Air Conditioning Contractors of America (ACCA) recommends a full visual sweep before testing begins.

3. Safety and Electrical Checks

-

Test safety switches, circuit boards, and wiring

-

Check for secure gas connections and leaks

-

Perform carbon monoxide testing for gas systems

4. Airflow and Ductwork Inspection

-

Measure static pressure with a manometer

-

Check for duct leaks, blockages, or undersized runs

ASHRAE standards highlight airflow testing as a critical step in ensuring efficiency and indoor air quality.

5. Heat Exchanger and Burner Assembly Check

-

Look for cracks or damage in heat exchangers

-

Clean and adjust burners for proper combustion

6. Filter and Thermostat Evaluation

-

Inspect filter condition and recommend replacement if needed

-

Test thermostat accuracy and settings

7. Efficiency Testing

-

Measure temperature rise and combustion efficiency

-

Use diagnostic tools to confirm system performance matches manufacturer specs

ENERGY STAR advises annual efficiency testing to maintain peak performance.

Tools Technicians Use

A thorough inspection requires professional-grade tools, including:

-

Digital manometer – for static pressure readings

-

Combustion analyzer – for efficiency and safety testing

-

Infrared thermometer – for temperature checks

-

Borescope camera – for internal component inspection

Common Issues Found During an Inspection

Inspections often uncover:

-

Dirty or damaged heat exchangers

-

Improper venting

-

Failing blower motors

-

Clogged condensate drains

Catching these early can prevent major repairs later.

How to Prepare for an HVAC Inspection

You can make the process smoother by:

-

Making a list of symptoms or performance issues

-

Clearing access to equipment and vents

-

Having past maintenance records ready

Home Comfort Alliance notes that homeowner preparation can make service visits faster and more effective.

How Often Should You Schedule an Inspection?

For most homes, once a year is the minimum. Older systems or those in heavy-use climates may benefit from seasonal checkups.

Skipping inspections may void warranties—many manufacturers, like Lennox, require proof of annual maintenance.

Final Report and Next Steps

After the inspection, your tech should give you a written report outlining:

-

What was inspected and tested

-

Any issues found and their urgency

-

Recommended repairs or replacements

If the report shows multiple costly repairs ahead, it may be time to consider replacement. You can learn what that process involves in HVAC Replacement Timeline: How Long Does It Really Take?

And if you’re still weighing your options, start with our main guide: Should You Replace or Repair Your HVAC System?

Final Thoughts

An HVAC inspection isn’t just about fixing what’s broken—it’s about preventing breakdowns, protecting your home, and helping you make smart repair-or-replace decisions.

When done right, it’s one of the best ways to extend your system’s life and ensure year-round comfort.

Alex Lane

Your Home Comfort Home