I’ve seen it too many times.

The system is mounted.

The wires are landed.

The thermostat is on the wall.

And someone says: “Alright… let’s fire it up.”

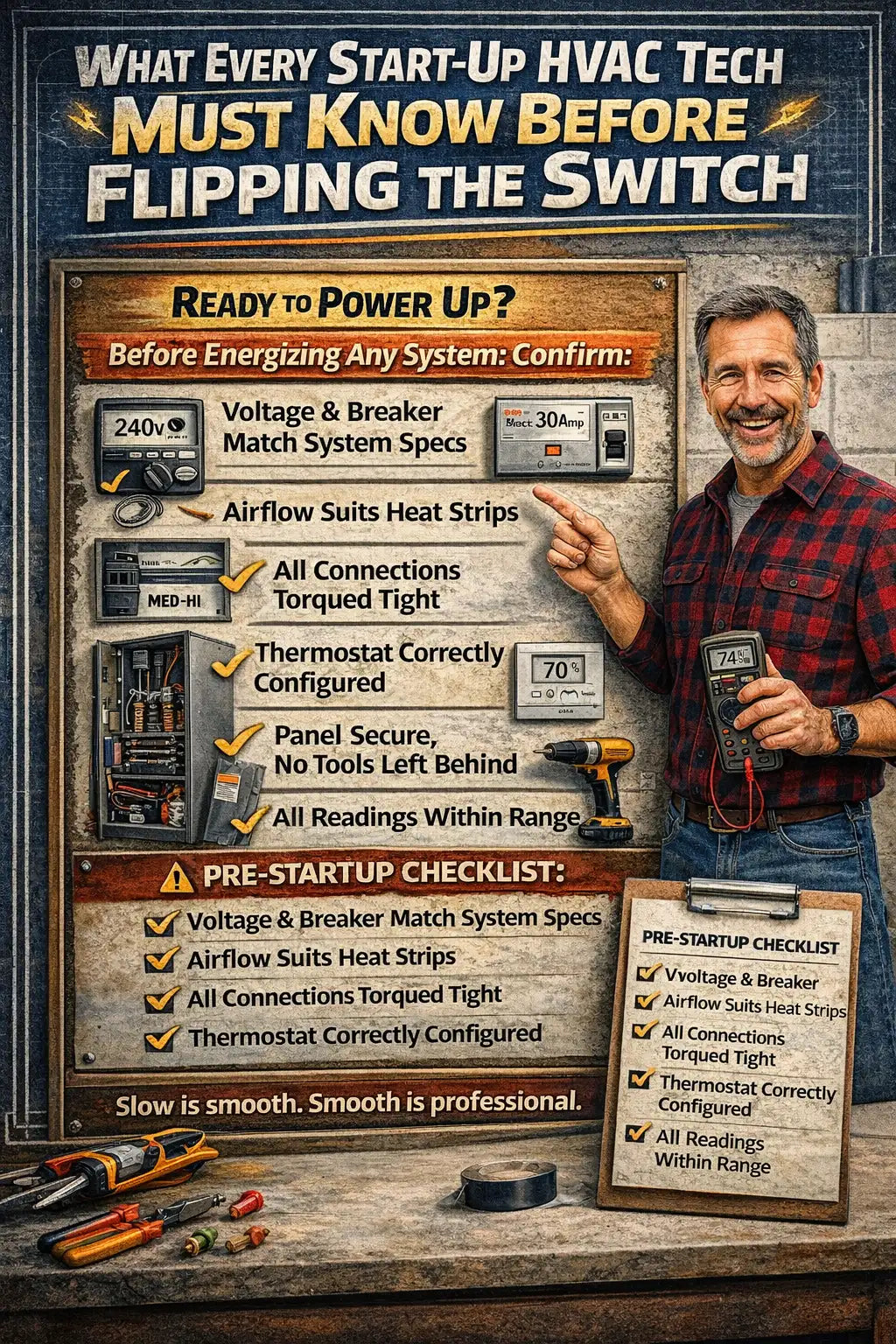

That moment—before the switch is flipped—is where good HVAC techs separate themselves from expensive mistakes. Especially for start-ups, that first power-up can either build confidence or create a callback you’ll never forget.

Goodman 68,240 BTU 20 kW Electric Furnace with 2,000 CFM Airflow - MBVK20DP1X00, HKTAD201

This guide is your pre-startup reality check. If you’re new, read this before you energize anything. If you’re experienced, use it as a checklist to stay sharp.

🔍 Why Start-Up Is the Most Dangerous Moment of Any Install

Startup is when:

-

Electrical mistakes show themselves

-

Airflow problems trigger limits

-

Loose connections start heating up

-

Manufacturer warranties get voided

Most equipment failures blamed on “bad units” are actually bad startups.

And here’s the truth no one likes to say out loud:

The newer you are, the more critical your startup process needs to be.

🧠 Rule #1: Understand the System You’re Powering

Before touching a breaker, you should be able to answer all three of these:

✅ What voltage does this system require?

Single-phase vs three-phase, correct breaker size, correct wire gauge.

✅ How much airflow does it need?

Electric furnaces, heat strips, and air handlers are unforgiving when airflow is wrong.

✅ What sequence should happen at startup?

Blower first? Heat strips staged? Time delay?

If you don’t know the answers, stop and read the manual. Goodman publishes detailed installation and startup documentation for a reason:

👉 https://www.goodmanmfg.com/resources

🧰 Electrical Basics Every Start-Up Tech Must Respect

🔌 Voltage Is Not a Suggestion

Before startup:

-

Verify incoming voltage at the disconnect

-

Check voltage under load, not just at rest

-

Confirm breaker size matches nameplate data

The NEC exists to keep people safe and equipment alive

Low voltage causes:

-

Heat strip damage

-

Contactor chatter

-

Premature failure

High voltage causes:

-

Burnt controls

-

Blower motor stress

-

Instant component death

🔩 Torque Matters More Than You Think

Loose electrical connections are silent killers.

Before startup:

-

Torque lugs to manufacturer specs

-

Re-check aluminum connections

-

Inspect factory terminals (don’t assume they’re tight)

A loose lug may run fine today—and melt tomorrow.

🌬️ Airflow: The #1 Startup Killer for New Techs

Electric heat lives and dies by airflow.

🚫 What Happens With Low Airflow

-

High-limit trips

-

Short cycling

-

Burned heat strips

-

Customer complaints within days

✅ What You Must Verify Before Startup

-

Correct blower speed setting

-

Proper duct sizing (or at least no major restrictions)

-

Clean filter installed

-

All registers open

ASHRAE airflow fundamentals explain why this matters:

👉 https://www.ashrae.org/technical-resources

If you can’t confidently estimate CFM, you’re gambling.

🔥 Heat Strip & Electric Furnace Startup Rules

Electric furnaces are not “plug and play.”

⚠️ Before Energizing Heat Strips

-

Confirm correct kW kit installed

-

Verify breaker sizing matches heat kit load

-

Ensure airflow supports total kW capacity

Oversized heat strips + undersized airflow = instant limit trips.

🧪 First Heat Cycle Test

-

Let the blower run first

-

Stage heat slowly

-

Monitor temperature rise

-

Listen for unusual noises or buzzing

If it smells a little on first run, that’s normal.

If it smells hot or electrical—shut it down.

🎛️ Thermostat Setup: Small Mistakes, Big Problems

A misconfigured thermostat can sabotage a perfect install.

🔧 Before Startup

-

Confirm correct system type selected

-

Verify electric heat vs heat pump settings

-

Check staging configuration

❌ Common Startup Thermostat Errors

-

Heat pump mode on electric furnace

-

Incorrect fan settings

-

Emergency heat miswired

Energy.gov explains how improper controls affect efficiency and safety:

👉 https://www.energy.gov/energysaver/energy-saver

📋 The Pre-Startup Checklist (Don’t Skip This)

Before flipping the switch, you should physically confirm:

-

✅ Breaker size and wire gauge match nameplate

-

✅ All panels secured

-

✅ Grounding properly connected

-

✅ Air filter installed

-

✅ Blower speed set correctly

-

✅ Thermostat configured properly

-

✅ No tools left inside cabinet (yes, it happens)

If you feel rushed, you’re not ready.

🚨 Red Flags During First Power-Up

Shut it down immediately if you notice:

-

Loud buzzing or humming

-

Burning electrical smell

-

Blower not running before heat

-

Breaker trip on first call

-

Repeated limit trips

Powering through problems doesn’t make you tough—it makes you liable.

📸 Why Start-Ups Must Document Startup

Take photos of:

-

Electrical connections

-

Blower settings

-

Heat kit labels

-

Voltage readings

Documentation:

-

Protects you from disputes

-

Helps with warranty claims

-

Builds professional credibility

Manufacturers expect proper startup documentation:

👉 https://www.ahrinet.org

💬 What You Should Explain to the Customer at Startup

Before leaving:

-

Explain normal first-run smells

-

Set thermostat expectations

-

Review filter maintenance

-

Tell them when to call you (and when not to)

Educated customers create fewer emergency calls.

🧱 The Biggest Startup Mistake New HVAC Techs Make

Trying to look confident instead of being correct.

Confidence comes after repetition, not before it.

If you:

-

Slow down

-

Follow the checklist

-

Respect airflow and electricity

You’ll build a reputation faster than any ad campaign ever could.

🧠 Mike’s Final Word

Flipping the switch isn’t the finish line—it’s the truth test.

Startup tells you:

-

If your install was solid

-

If your planning was right

-

If you respected the system

Do it right, and your first installs build momentum.

Do it wrong, and they bury you in callbacks.

Slow is smooth.

Smooth is professional.

Professional is profitable.