Savvy Mavi — Sustainable HVAC Designer & Architectural Acoustics Enthusiast

If you’ve ever walked into a hotel room and thought,

“Wow, this PTAC is so quiet!”

…you’re not imagining it.

Hotels engineer something that most homeowners overlook completely: the wall itself.

Your PTAC’s performance — cooling depth, heating stability, sound level, even lifespan — is directly influenced by the thickness, density, and construction quality of the wall that holds it.

And when you bring PTACs into residential spaces — bedrooms, offices, bonus rooms, basements, ADUs — you bring with them the architectural question no one asks but everyone should:

Amana J-Series PTAC Model 17,000 BTU PTAC Unit with 5 kW Electric Heat

👉 Is my wall built to support quiet, efficient PTAC comfort?

Let’s peel back the layers (literally) and reveal how wall thickness determines noise, airflow, vibration, and the overall vibe of your comfort system.

🧐 1. Why Wall Thickness Matters More Than the PTAC Brand

It doesn’t matter if you buy the quietest PTAC on the market — if the wall is thin, hollow, or poorly built, you’ll hear:

-

compressor hum

-

fan vibration

-

outdoor noise leaking in

-

resonance from the sleeve

-

airflow turbulence

Even a premium Amana J-Series or GE Zoneline can sound loud in the wrong wall.

Wall thickness influences:

-

sound transmission

-

vibration travel

-

outdoor noise infiltration

-

sleeve movement

-

thermal retention

-

PTAC cycling frequency

A thick, dense, well-built wall =

✔ quieter PTAC

✔ fewer temperature swings

✔ more efficient system runtime

✔ long-term stability

A thin, hollow, poorly insulated wall =

❌ louder PTAC

❌ frequent cycling

❌ cold drafts

❌ wasted BTUs

And the kicker?

A PTAC doesn’t generate most of its own noise — the wall amplifies it.

🔊 2. The Science of Noise: 90% Structure, 10% Machine

Let’s break sound into two categories:

🧩 Airborne noise

Sound traveling through the air, like:

-

fan noise

-

compressor tone

-

outdoor traffic

-

birds, people, or wind

🧱 Structure-borne noise

Sound traveling through the wall, like:

-

vibration from the PTAC sleeve

-

hum of compressor

-

rumble from coil startup

-

wall panel shaking

Most homeowners only focus on airborne noise.

But PTACs are structure-connected appliances, meaning structure-borne noise is the real enemy.

And what determines structure-borne noise?

👉 Wall thickness

👉 Wall materials

👉 Wall density

👉 Wall construction

👉 Sleeve sealing

Hotels know this.

Most residential installations ignore it.

Verified External Link

Basics of sound transmission (EPA Noise Control):

https://www.epa.gov/indoor-air-quality-iaq

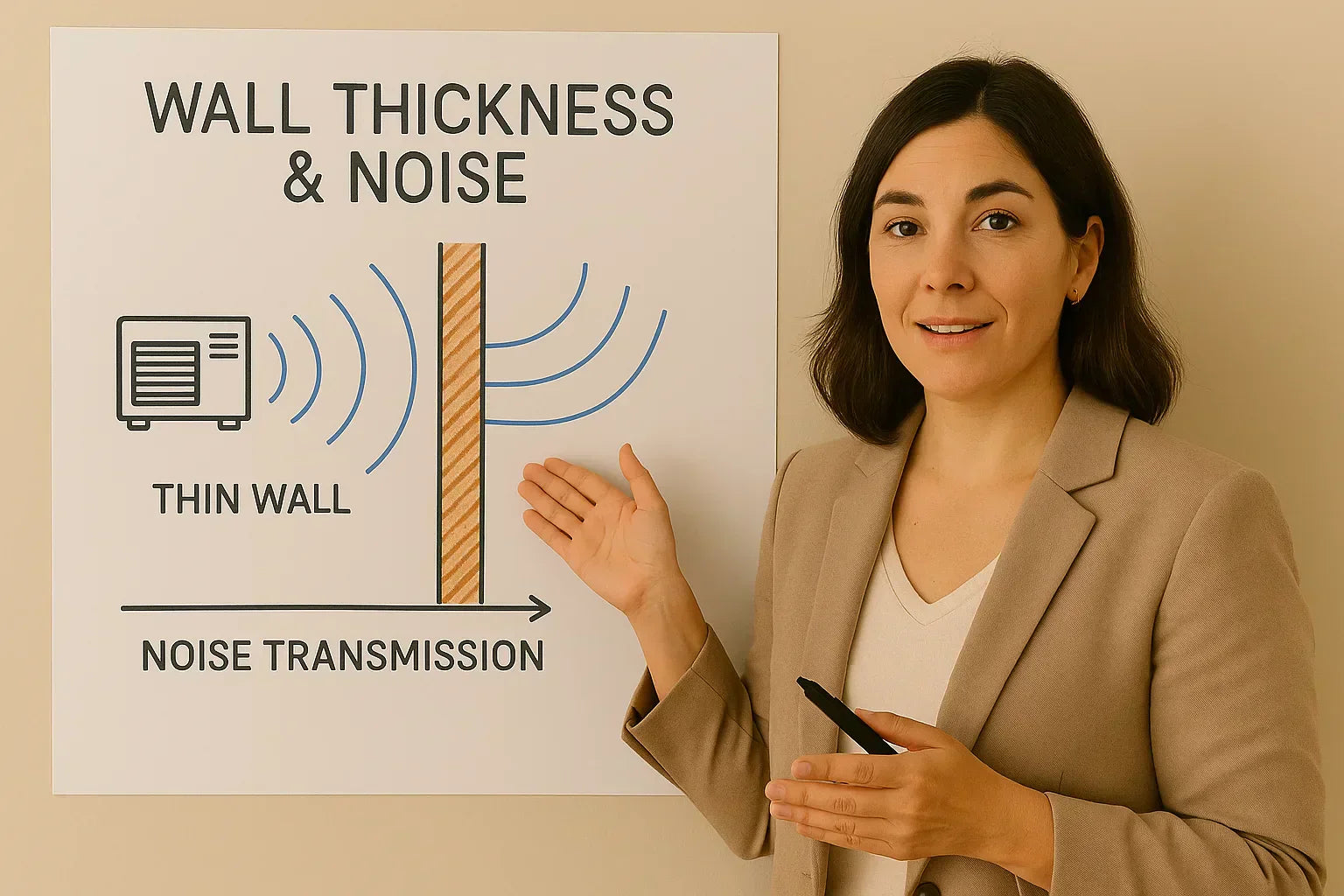

🧱📐 3. How Different Wall Thicknesses Affect PTAC Noise

Let’s go through common wall types used in homes and small buildings.

🟩 8-inch masonry or concrete (hotel standard)

-

extremely quiet

-

best vibration absorption

-

ideal for PTACs

-

minimal outdoor noise

-

stable thermal mass

This is why hotels use PTACs so successfully.

🟨 6-inch insulated stud wall (modern homes)

-

good airborne sound control

-

moderate structure-borne isolation

-

quiet enough for PTACs with proper sleeve foam

🟦 4-inch interior partition (older homes / garages)

-

hollow or poorly insulated

-

transfers vibration easily

-

PTACs sound far louder

-

poor thermal control

🟥 2×3 or hollow walls (renovations, basements, DIY builds)

-

worst for PTACs

-

no density

-

sleeve resonates

-

wall becomes a “speaker box”

Savvy Verdict

If the wall is thin, even the quietest PTAC becomes noisy.

If the wall is thick, even a budget PTAC sounds premium.

📦 4. The Wall Sleeve: The Acoustic Bridge Nobody Talks About

Your PTAC sits inside a wall sleeve, which is both:

-

a structural anchor

-

an acoustic conduit

If the sleeve vibrates, the wall vibrates. If the wall vibrates, you vibrate with frustration.

What causes sleeve noise?

-

loose installation

-

gaps around sleeve

-

no foam sealing

-

sleeve touching studs

-

condensation

-

poorly anchored exterior grille

Hotel-style sleeve installation uses:

-

foam perimeter fill

-

vibration pads

-

sealed joints

-

insulated sleeves

-

matched exterior grilles

-

perfectly level placement

A $600 PTAC installed with a $0 installation mindset = loud.

A $600 PTAC installed with a hotel-grade sleeve strategy = whisper quiet.

Verified External Link

DOE guidelines for sealing building penetrations

🧊🌬 5. How Thermal Mass Helps Your PTAC Work Less (and Sound Quieter)

Thick walls don’t just block noise — they stabilize temperature.

Why this matters:

🧊 In cooling mode:

Rooms with stable walls don’t heat up as quickly → PTAC cycles less often.

🔥 In heating mode:

Walls hold warmth → less electric strip activation → quieter operation.

🌡 Stable walls =

-

fewer spikes in outdoor heat load

-

longer, smoother PTAC cycles

-

reduced compressor noise

-

quieter nighttime operation

Verified External Link

DOE home envelope & thermal mass guidance

📍🛏 6. Bedroom Installations: Why Wall Thickness Matters Even More

Bedrooms amplify noise because:

-

you’re closer to the unit

-

nighttime silence makes small noises noticeable

-

walls reflect low-frequency hum

-

mattress & headboard position change acoustics

A PTAC on a thin wall behind your headboard =

❌ nighttime vibration

❌ low-frequency droning

❌ audible cycling

❌ poor sleep

A PTAC on a dense external wall across from the bed =

✔ quiet

✔ stable

✔ more consistent airflow

✔ comfortable sleep

Hotels ALWAYS place PTACs where beds won’t pick up vibration.

You should too.

🔨 7. Retrofitting Walls for PTAC Comfort (Savvy’s Upgrade List)

If your walls aren’t hotel-grade, don’t panic. We can fix that.

🟩 Best upgrades for noise control:

-

add insulation (rockwool is best for sound)

-

double up drywall

-

use resilient channels

-

add mass-loaded vinyl (MLV) behind sleeve area

-

add acoustic caulk around sleeve

-

upgrade exterior grille

-

seal all gaps around the sleeve

🟦 Best upgrades for thermal control:

-

insulate exterior cavities

-

weatherstrip nearby windows

-

add low-e film

-

block solar gain with curtains

-

foam seal wall penetration

These upgrades reduce:

-

cycling

-

overshoot

-

compressor strain

-

incoming outdoor noise

-

temperature instability

🔍📊 8. Test Your Wall the Savvy Way (Tools You Already Have!)

Using your airflow/temperature meter

Measure:

✔ Temperature stability

If wall temperatures swing >4°F in an hour, envelope is weak.

✔ Outdoor noise intrusion

Hold meter mic near sleeve area.

✔ Return airflow temperature

Thin walls may create thermal drafts.

✔ PTAC vibration

Place hand on wall — you’ll feel resonance.

✔ Leakage

Use smoke test or incense around sleeve edges.

This is how you turn observations into actionable design.

🪟🌁 9. Windows + Wall Thickness = The Acoustic Combo That Makes or Breaks PTAC Sound

Windows are often the weakest link in PTAC rooms.

Thin walls + thin windows =

the perfect storm of noise, drafts, and cycling.

Hotel-grade window strategies:

-

heavy curtains

-

double-pane glazing

-

low-E film

-

sealed frames

-

minimal air infiltration

Verified External Link

Energy-efficient window guidance:

https://www.energy.gov/energysaver/energy-efficient-window-coverings

🧹🔧 10. Maintenance + Wall Quality = Silent Operation

Even the best wall and sleeve setup gets noisy if maintenance is ignored.

Must-do tasks:

-

clean PTAC filters monthly

-

clean blower wheel

-

vacuum coil surface

-

tighten panel screws

-

lubricate fan motor (if applicable)

-

clean exterior grille

-

reseal sleeve every 2–3 years

A healthy PTAC + healthy wall = the absolute quietest combination possible.

🧠 11. Acoustic Myths Homeowners Believe (and Why They’re Wrong)

❌ Myth 1: “A quieter PTAC will fix everything.”

If the wall vibrates? Nope.

❌ Myth 2: “Soundproofing foam works.”

It only absorbs high frequencies, not PTAC hum.

❌ Myth 3: “Carpet reduces PTAC noise.”

Floor covering ≠ wall vibration control.

❌ Myth 4: “I’ll install it anywhere — it’s small.”

Placement + wall thickness = 70% of performance.

🌱💡 12. Sustainability Bonus — Thick Walls Cut Carbon

Stable walls reduce:

-

runtime

-

BTU demand

-

heat strip activation

-

compressor cycles

-

energy waste

A PTAC in a well-insulated, dense wall uses up to 25–40% less energy over a season.

That’s a massive carbon reduction for such a simple architectural choice.

🧘♀️ 13. Final Thoughts — PTAC Comfort Isn’t About the PTAC Alone

It’s about the room it lives in.

Your PTAC is only as quiet, efficient, and stable as the wall that supports it.

Thicker walls =

✔ Quiet nights

✔ Steady temperatures

✔ Lower energy bills

✔ Longer equipment life

✔ Better humidity control

Thin walls =

❌ louder system

❌ frequent cycling

❌ overheating or overcooling

❌ wasted BTUs

❌ inconsistent comfort

Sustainable comfort is holistic.

And it starts not with the equipment —

but with the architecture.

Design the wall. Design the airflow. Design the envelope. Design the comfort. Stay thoughtful. Stay efficient. Stay Savvy. 🌿✨

Buy this on Amazon at: https://amzn.to/434DIng

In the next topic we will know more about: Room-by-Room System Design — Creating Microclimates Without Wasting Energy