By Savvy Mavi — Your Eco-Modern HVAC Designer & Comfort Strategist

Here’s the truth no one tells homeowners:

Most PTAC setups are designed for today — not tomorrow.

They’re installed to fix a comfort problem fast:

-

that too-warm bedroom

-

that stuffy bonus room

-

that under-conditioned basement office

-

that converted garage with its own personality

-

that ADU you’re trying to get Airbnb-ready

But homes evolve. Floorplans change. Rooms get repurposed. Families grow. And if your PTAC layout isn’t engineered with future upgrades in mind, you’ll eventually face:

-

expensive rewiring

-

relocations

-

airflow redesign

-

mismatched BTUs

-

blown circuits

-

clogged sleeves

-

overshoot or short-cycling

-

loud airflow right where you sleep

Future-proof design is the only design that actually saves money in the long run.

This is the guide that hotel engineers, commercial HVAC designers, and sustainability consultants (aka me 💁♀️) use to create PTAC layouts that stay efficient, quiet, and scalable for 10–20 years.

Amana J-Series PTAC Model 17,000 BTU PTAC Unit with 5 kW Electric Heat

Let’s build comfort that grows with your home — not against it.

🧭 1. What Does It Mean to “Future-Proof” a PTAC Layout?

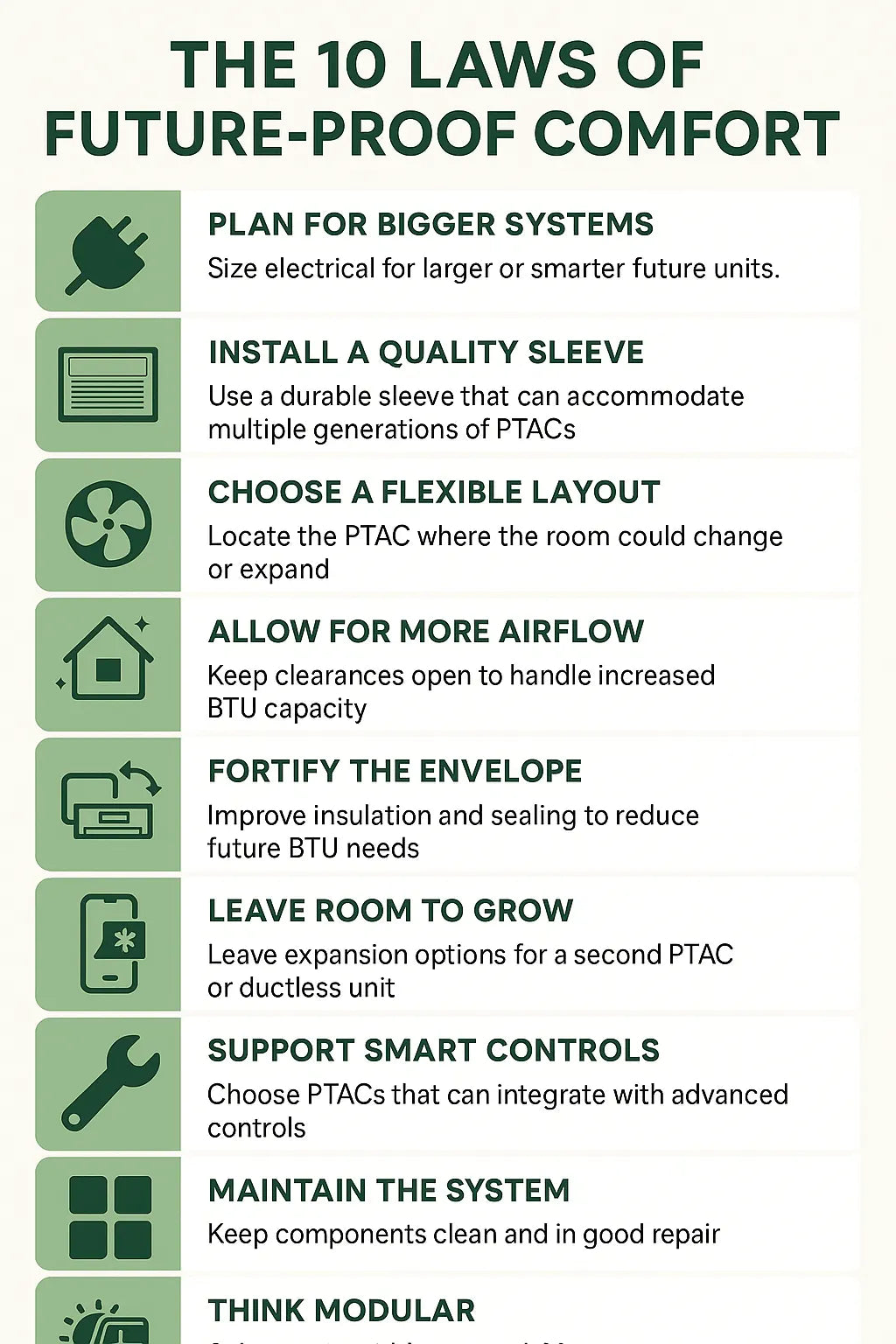

Future-proofing means designing the infrastructure, airflow, electrical load, structural support, and layout so your PTAC system can:

-

upgrade from 7k → 9k → 12k → 15k BTU

-

add heat pump support

-

expand into adjacent rooms

-

relocate without major construction

-

support smart controls

-

integrate with solar or battery systems

-

maintain efficiency as your home’s use changes

Instead of being a fixed appliance, a future-proofed PTAC becomes part of a modular comfort system.

🔌 2. Step One: Electrical Planning That Allows for Larger or Smarter Units

Electrical mistakes are the #1 reason PTAC upgrades become expensive.

Here’s the Savvy rule:

Always install electrical infrastructure for the next size up, not the current one.

For example:

If you’re installing a 12,000 BTU PTAC today:

📌 Install wiring & breaker sized for 15,000–17,000 BTUs (208/230V, 20–30A)

If you’re adding a heat strip (3.5 kW, 5 kW):

📌 Design the circuit for the largest strip your model line supports.

Future-Proofed Electrical Checklist:

-

✓ dedicated circuit

-

✓ proper NEMA plug type (6-20P, 6-30P)

-

✓ breaker sized at 125% of max load

-

✓ wiring gauge sized for future amperage

-

✓ outlet placed where the unit might move later

-

✓ surge protection (future heat pumps are sensitive!)

Verified Link

DOE electrical safety & load planning

🧊🌡 3. Step Two: Choose a Wall Sleeve That Supports Multiple Generations

The wall sleeve is the forever part of a PTAC installation.

A good wall sleeve can last:

-

20+ years

-

through multiple PTAC upgrades

-

through refrigerant transitions

-

through capacity changes

A cheap sleeve?

You’ll rip it out. And the drywall with it.

Future-Ready Sleeve Features:

-

✔ universal dimensions (42"x16" is standard)

-

✔ proper insulation

-

✔ room for deeper or taller chassis

-

✔ sealed exterior grille

-

✔ water channeling for future drain configurations

-

✔ ability to add sleeve baffles for quieter units

Why this matters:

Future PTACs may use:

-

R-32

-

inverter compressors

-

smart sensors

-

quieter cross-flow blowers

-

deeper coil assemblies

Your sleeve must accommodate all of these without remodeling.

Verified Link

EPA guidance on sealing penetrations (applies to sleeves too):

https://www.epa.gov/indoor-air-quality-iaq

🛋 4. Step Three: Layout the Room for 5–10 Years of Flexibility

This part is where the real eco-design magic happens.

Your PTAC layout shouldn’t only suit what your room looks like today.

It should anticipate:

-

new furniture

-

changing traffic flow

-

potential bed relocation

-

converting the room into a nursery

-

turning the space into a home office

-

adding a second PTAC in the future

-

expanding airflow to the next room over

The Savvy “Future Layout Grid”:

Create a grid with two PTAC-friendly walls:

-

Wall A: primary PTAC location

-

Wall B: secondary PTAC location (future option)

This lets you:

-

move the unit without new wiring

-

change room purpose without airflow chaos

-

avoid redesign when BTU needs change

Avoid:

❌ placing PTACs behind beds

❌ installing under drapes

❌ blocking return airflow

❌ placing in narrow alcoves

❌ installing near closet doors

Future flexibility requires breathable, open airflow space.

🌬 5. Step Four: Airflow Planning That Scales With BTUs

Future PTACs may:

-

blow harder

-

use inverter ramps

-

modulate airflow

-

support increased CFM

You need an airflow corridor that won’t break when capacity changes.

✔ Build a “Wind Path”

Air should travel the room’s longest dimension.

✔ Maintain 12–18 inches clear space in front

All future units need it.

✔ Avoid furniture zones that trap future airflow

Especially:

-

tall bookcases

-

bed footboards

-

media centers

-

high-back chairs

✔ Include ceiling fan support

Future PTACs + ceiling fans = smooth temperature curves + less overshoot.

Verified Link

ASHRAE airflow fundamentals:

https://www.ashrae.org/technical-resources

🧱 6. Step Five: Build the Thermal Envelope for the Worst-Case Future System

Your PTAC shouldn’t have to work harder later.

If you refine the envelope today, your future BTU needs drop automatically.

Must-Do Envelope Work:

-

air seal windows

-

foam seal the sleeve

-

insulate exterior walls

-

upgrade attic insulation

-

install low-E curtains or film

-

seal baseboards and trim gaps

Why this is future-proofing:

A tight envelope allows you to:

-

downsize or right-size future PTACs

-

reduce compressor wear

-

decrease cycling

-

avoid needing higher BTU units later

-

support heat pump upgrades that require tight conditions

A PTAC grows best in a healthy envelope.

🔄 7. Step Six: Plan for Multi-Zone or Add-On Capability

Future homeowners often want:

-

a second PTAC

-

a PTAC + ductless mini split combo

-

a PTAC to condition an adjacent room

-

a PTAC-assisted whole-house layout

Plan for this now by:

-

installing a second wall sleeve location

-

leaving conduit paths open

-

ensuring electrical panel has spare capacity

-

placing PTAC near shared wall for airflow expansion

-

allowing for future thermostatic integration

Hotels design PTAC rooms with expansion in mind.

Homes should do the same.

Verified Link

DOE zoning strategies (applies to room-based PTAC zoning)

📱 8. Step Seven: Smart Controls That Adapt Over Time

Your PTAC’s controls should evolve with your home.

Choose systems that support:

-

external thermostats

-

WiFi or app control

-

occupancy sensing

-

API integration

-

smart cycling

-

energy monitoring

-

staged heating logic

-

lockout settings

-

humidity control

Even if your PTAC doesn’t need these now, your future PTAC might.

Verified Link

EnergyStar smart thermostat guidance:

https://www.energystar.gov/products/smart_thermostats

🛠 9. Step Eight: Maintenance That Keeps Future Options Open

Future upgrades work best when the existing system ages gracefully.

Do these yearly:

-

clean blower wheel

-

vacuum return path

-

reseal sleeve edges

-

inspect electrical contacts

-

check drain pan

-

clean coils

-

refresh external grille seal

Good maintenance prevents the need for premature replacements — giving you time to plan upgrades on your terms, not emergency terms.

🔍 10. Step Nine: Build With Modular Components

Hotel designers do this.

Commercial engineers do this.

Smart homeowners should too.

Modular components include:

-

removable grilles

-

replaceable drain pans

-

universal thermostats

-

upgrade-friendly sleeves

-

standardized plug types

-

reversible louvers

-

detachable front panels

-

swappable filters

A modular PTAC ecosystem means you only replace what’s needed — not the entire installation.

🔋 11. Step Ten: Plan for Solar, Battery, or Grid-Support Features

Future HVAC = less grid dependency.

Design so your PTAC can eventually be supported by:

-

rooftop solar

-

battery storage systems

-

smart load controllers

-

demand-response programs

-

variable-power inverters

Future-ready electrical planning reduces peak loads and helps your PTAC run on cleaner energy.

🧠 12. Final Thoughts — The Future Loves a Flexible Home

Designing for future upgrades is not about predicting the future.

It’s about removing limitations.

A PTAC layout that grows with your home is:

-

flexible

-

modular

-

quiet

-

efficient

-

envelope-optimized

-

airflow-friendly

-

scalable

-

sustainable

And most importantly — it prevents you from spending thousands on redesigns years down the line.

Design for the room you have now.

Prepare for the home you’ll have next.

Future-proofing = sustainability, comfort, and savings in one beautiful package.

Stay future-ready.

Stay efficient.

Stay Savvy. 🌿✨

Buy this on Amazon at: https://amzn.to/434DIng

In the next topic we will know more about: Wall Thickness & Real-World Noise — The Architectural Secret Behind PTAC Comfort