If you’ve ever measured your room, bought what seemed like the perfect-sized air conditioner, and still ended up uncomfortable — you’re not alone.

Jake’s seen it happen more times than he can count: a homeowner buys a “just right” 12,000 BTU wall unit, installs it in a slightly off-center cutout, uses the wrong sleeve, and suddenly it’s performing like a 9,000 BTU.

“You can size your system perfectly on paper,” Jake says, “but if your airflow’s choked off by bad installation, your BTUs are as good as gone.”

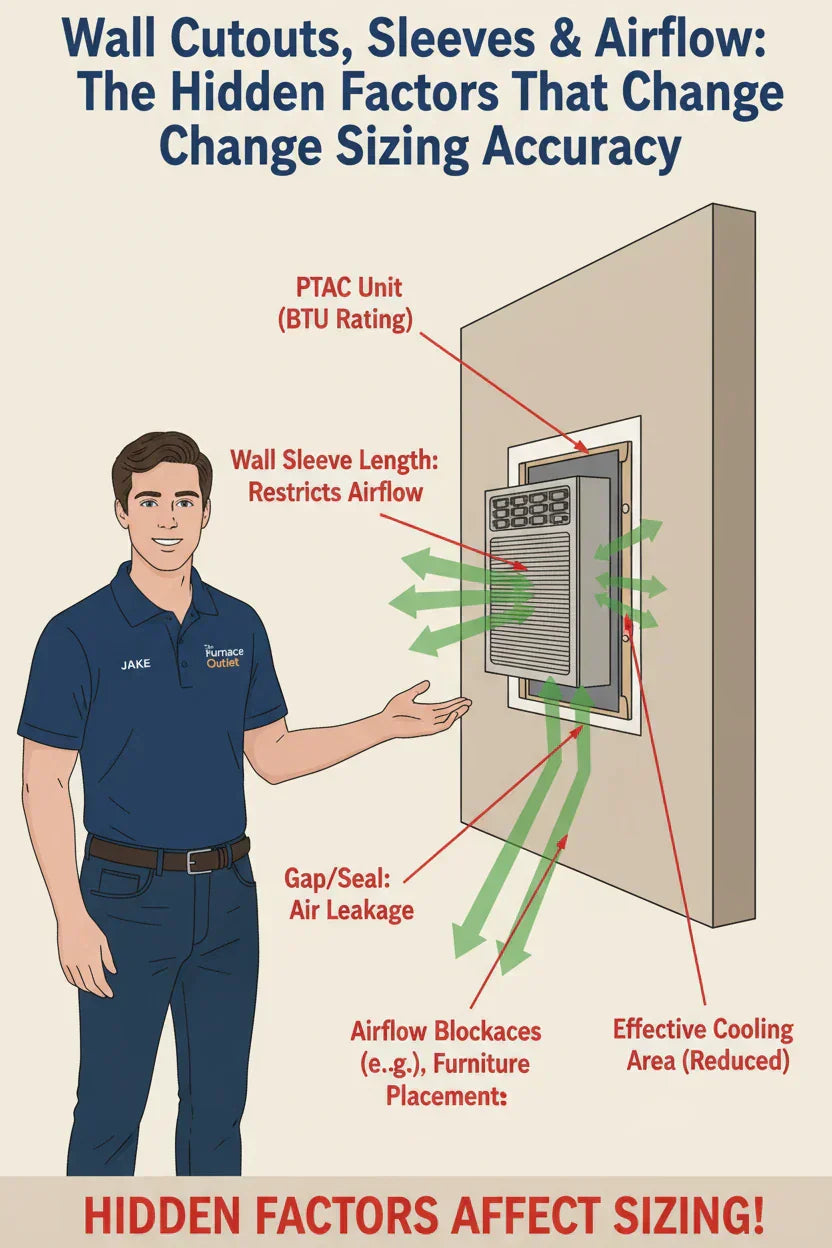

In other words — sizing accuracy doesn’t stop at the calculator. Wall cutouts, sleeves, filters, and airflow direction all affect how much cooling or heating your system can actually deliver.

Let’s break down the hidden factors that make or break your system’s performance — and how to fix them for maximum comfort.

We’ll use the Amana Distinctions 12,000 BTU PTAC with 3.5 kW Electric Heat as our baseline. It’s one of Jake’s favorites for reliable airflow, quiet operation, and balanced temperature — but even it needs a correct install to hit full efficiency.

🧠 Why Installation Details Matter More Than You Think

When a PTAC or wall unit is tested in a lab, it’s operating in ideal conditions: perfect airflow, balanced pressure, clean filters, and no obstructions.

But your wall isn’t a lab.

Even a half-inch gap around the sleeve or a slightly angled vent can alter airflow enough to change effective BTU output by 10–20%.

Jake explains:

“Every BTU your system makes has to move through air. Block that air — with dust, depth, or bad design — and your system loses muscle.”

Here’s the hidden truth:

You can lose up to one-third of your rated capacity just from small airflow issues. That means your 12,000 BTU unit might be performing closer to 8,000 BTU in the real world.

Let’s look at where those BTUs go missing.

🔗 Reference: Energy Star – Proper AC Installation

🧩 Wall Cutouts: Why Size, Depth, and Sealing Matter

Every wall unit or PTAC has specific dimensions for its wall sleeve and cutout. These aren’t just for convenience — they ensure that airflow can travel freely through the coil, sleeve, and vent path.

🔹 Problem 1: Undersized or Irregular Cutouts

If your wall opening is too tight or irregular, the rear exhaust and intake airflow gets restricted. That raises static pressure, forcing the fan motor to work harder.

What happens next:

-

The system overheats internally.

-

Efficiency drops by 10–15%.

-

Noise and vibration increase.

🔹 Problem 2: Cutouts Too Deep for the Wall Sleeve

If the wall is thicker than the sleeve depth, the rear airflow vent sits partially recessed — blocking exhaust.

Jake says:

“Think of it like trying to breathe through a straw pressed against a wall. Your system’s lungs can’t move air.”

Ideal Setup (for Amana PTACs):

-

Cutout: 42" wide × 16" high × 13 ¾" deep

-

Sleeve flush with outdoor wall surface

-

Sealed gaps with foam gaskets or weatherproof caulk

🔹 Problem 3: Poor Sealing Around the Sleeve

If there are gaps around your sleeve, hot outdoor air can leak back into the intake, creating a recirculation loop. That makes your AC fight against itself.

Jake calls this the “hot breath problem”:

“You’re exhaling hot air and sucking it right back in. No wonder it’s losing its cool.”

Fix:

-

Use manufacturer-approved gaskets or closed-cell foam.

-

Seal all edges — top, sides, and bottom — without blocking vents.

🔗 Reference: Amana PTAC Installation Manual

🧰 Sleeves: The Most Overlooked Sizing Variable

The sleeve is the unsung hero of every PTAC system. It’s the metal or composite “shell” that holds your unit in place, supports ventilation, and protects against weather.

But here’s what most homeowners don’t realize: the sleeve affects airflow as much as the unit itself.

🔸 Wrong Sleeve Depth

If the sleeve is too deep, the fan has to push air through extra distance and turbulence, creating back pressure.

If it’s too shallow, air can leak around the rear edge, reducing cooling efficiency.

🔸 Wrong Sleeve Material

Metal sleeves are durable but conduct heat. If they’re exposed to direct sun, they radiate heat back into the unit.

Polymer sleeves insulate better but may flex or warp if misaligned.

| Sleeve Type | Material | Ideal For | Pros | Cons |

|---|---|---|---|---|

| Galvanized Steel | Metal | Hotels, exteriors | Durable, weatherproof | Conducts heat, heavier |

| Polymer/Composite | Plastic | Homes, retrofits | Quiet, lightweight | Needs reinforcement |

| Universal Retrofit | Mixed | Replacements | Fits various brands | Must seal carefully |

Jake’s rule:

“The sleeve and unit are a matched set — if they’re not in sync, your BTUs will leak out the back.”

🔸 Retrofit Mistakes

Homeowners often reuse old sleeves from retired models. But even minor changes in vent design or fan geometry mean your new PTAC may not breathe right.

If your sleeve’s off by more than ½ inch, you’re losing airflow and capacity.

🔗 Reference: GE Zoneline & Amana Sleeve Compatibility Guide

🌬️ Airflow Path & Room Layout: The Invisible Comfort Killer

Your AC doesn’t just cool — it circulates air across the room. The way your room is laid out dramatically affects how that air moves.

Jake likes to compare it to highway traffic:

“If your air doesn’t have lanes to move, it’ll bottleneck. You’ll end up with cold corners and hot hallways.”

Common Airflow Mistakes

-

Blocked vents: Curtains, furniture, or plants directly in front of the unit.

-

Corner installs: Units shoved into wall corners can’t distribute air evenly.

-

No clearance: If the intake grille is flush against a table or bed, airflow suffocates.

-

Improper tilt: Every wall unit needs a slight outward slope (¼ to ½ inch) to drain condensation properly.

How to Fix It

✅ Keep 3 feet of clearance in front of the unit.

✅ Avoid furniture directly opposite the vent.

✅ Use oscillating fans or ceiling fans for long or open spaces.

✅ If you must install in a corner, redirect airflow with a deflector grille.

Even perfect BTU sizing won’t help if the cooled air can’t mix with the rest of the room.

🔗 Reference: ASHRAE – Airflow Fundamentals

🔧 Filters, Return Air & Coil Cleanliness

Air filters and coil surfaces directly impact how efficiently your system exchanges heat. When airflow is restricted by dust, pet hair, or lint, cooling performance drops drastically.

Jake says:

“Sizing charts assume clean filters. The second your filter clogs, your AC’s on a diet it never agreed to.”

Dirty Filter Effects

-

Cuts airflow by up to 25%

-

Raises coil temperature → compressor strain

-

Reduces BTU output

-

Shortens system life

Maintenance Schedule

-

Clean washable filters monthly

-

Replace disposable filters every 2–3 months

-

Inspect coil fins each season; straighten bent ones

Pro Tip: A quick way to test airflow — hold a sheet of tissue near the intake grille.

-

If it sticks gently, airflow’s good.

-

If it falls or barely moves, your filter’s choking performance.

🔗 Reference: Energy.gov – AC Maintenance Tips

🔥 External Air & Pressure Balance

Most PTACs, including Amana’s, are designed to draw in a small percentage of outdoor air to maintain indoor air quality. But if that intake is blocked or misused, it throws off pressure balance and humidity control.

Problems Jake Sees:

-

Homeowners seal outdoor louvers thinking it saves energy — it doesn’t.

-

Vent control levers stuck in “closed” position.

-

Leaves or debris clogging outdoor grille.

Consequences:

-

Reduced fresh air = stuffy indoor air

-

Pressure imbalance = noise and reduced airflow

-

Poor humidity control

Jake says:

“Your system breathes in and out like you do. Tape its nose shut, and it’ll start wheezing before summer’s over.”

Check the vent lever every season, especially if your climate shifts from humid to dry.

🧊 The Real-World BTU Loss Chart

Here’s what Jake’s seen in the field — how common mistakes eat into performance:

| Cause | Estimated BTU Loss |

|---|---|

| Poor wall sealing | 5–10% |

| Wrong sleeve depth | 10–20% |

| Dirty filters | 15–25% |

| Blocked vents or airflow | 10–15% |

| Multiple combined issues | 25–40% |

That means your “12,000 BTU” system might be delivering as little as 7,200 BTUs once installation errors and airflow restrictions are factored in.

Jake says:

“It’s like buying a 300-horsepower car and then driving it with the parking brake half on.”

🔗 Reference: ACCA – Manual S Airflow & Duct Design Standards

🧰 Jake’s 5-Minute Airflow Audit

Here’s Jake’s quick inspection method — no fancy tools required:

-

Remove the front grille.

Check for dust buildup or blocked coils. -

Look at the sleeve alignment.

The rear vent should sit flush with the outer wall, not recessed. -

Inspect weather seals.

Replace cracked or missing foam to stop hot air infiltration. -

Test airflow.

Hold a tissue near intake — you should see steady pull. -

Measure temperature split.

Air coming out should be about 15–20°F cooler than what’s going in.

If you fail two or more of those tests, airflow loss could be costing you hundreds annually.

Jake’s rule of thumb:

“Your system should inhale and exhale evenly — if one side’s struggling, your wall’s the culprit, not your thermostat.”

💡 Fixing Airflow Problems Without Buying a New Unit

Before upgrading your system, try these fixes:

For Oversized Units

-

Open doors or vent air into adjacent rooms.

-

Use fans to help distribute air.

-

Add insulation to balance cooling load.

For Undersized Units

-

Improve sealing and insulation.

-

Remove blockages from intake and discharge.

-

Upgrade filters for higher airflow efficiency.

-

Add a booster fan or ductless mini split if needed.

Jake’s tip:

“A $50 airflow fix beats a $5000 replacement nine times out of ten.”

🔗 Reference: Energy.gov – HVAC Load Management

📏 Jake’s Installation Checklist for Sizing Accuracy

Jake never signs off on a PTAC install until these boxes are checked:

✅ Wall cutout dimensions match manufacturer specs

✅ Sleeve depth flush with outdoor wall face

✅ Foam gasket installed around entire sleeve perimeter

✅ Unit tilted outward ¼–½ inch for drainage

✅ Filters clean and seated properly

✅ 3 feet of front clearance for discharge airflow

✅ Outdoor louvers clear and vent lever properly set

Jake’s takeaway:

“The difference between a good install and a great one is airflow. You can’t see it, but you can definitely feel it.”

🌡️ Real-World Example: The “90% System”

Jake once helped a small motel in South Carolina that had installed 20 brand-new PTACs — but every room was still too warm.

The culprit?

Each wall sleeve was set 1½ inches too deep into the concrete wall. That blocked exhaust airflow and reduced effective capacity by 15–18%.

By simply adjusting and resealing the sleeves, the systems instantly started cooling properly — with no equipment change.

Jake laughs:

“They were about to replace $30,000 worth of units. All they needed was a tape measure and an afternoon.”

🧭 Jake’s Final Word

“Sizing accuracy isn’t just about numbers. It’s about the wall, the sleeve, and the air that moves through it.”

Even the best HVAC system can’t beat physics. A misaligned sleeve, blocked vent, or dirty filter can undo all your careful planning and cut your effective BTU output in half.

So before you blame your system for not keeping up, check its environment. Your wall, your airflow path, and your filters might be stealing comfort one cubic foot at a time.

Jake’s bottom line:

“Don’t upgrade your BTUs — upgrade your airflow.”

And if you want a system built to perform even in real-world conditions, Jake recommends the Amana Distinctions 12,000 BTU PTAC with 3.5 kW Electric Heat — engineered for optimized airflow, easy maintenance, and reliable comfort year-round.

Buy this on Amazon at: https://amzn.to/3WuhnM7

In the next topic we will know more about: How Humidity Changes the Math: Sizing for Wet vs. Dry Environments