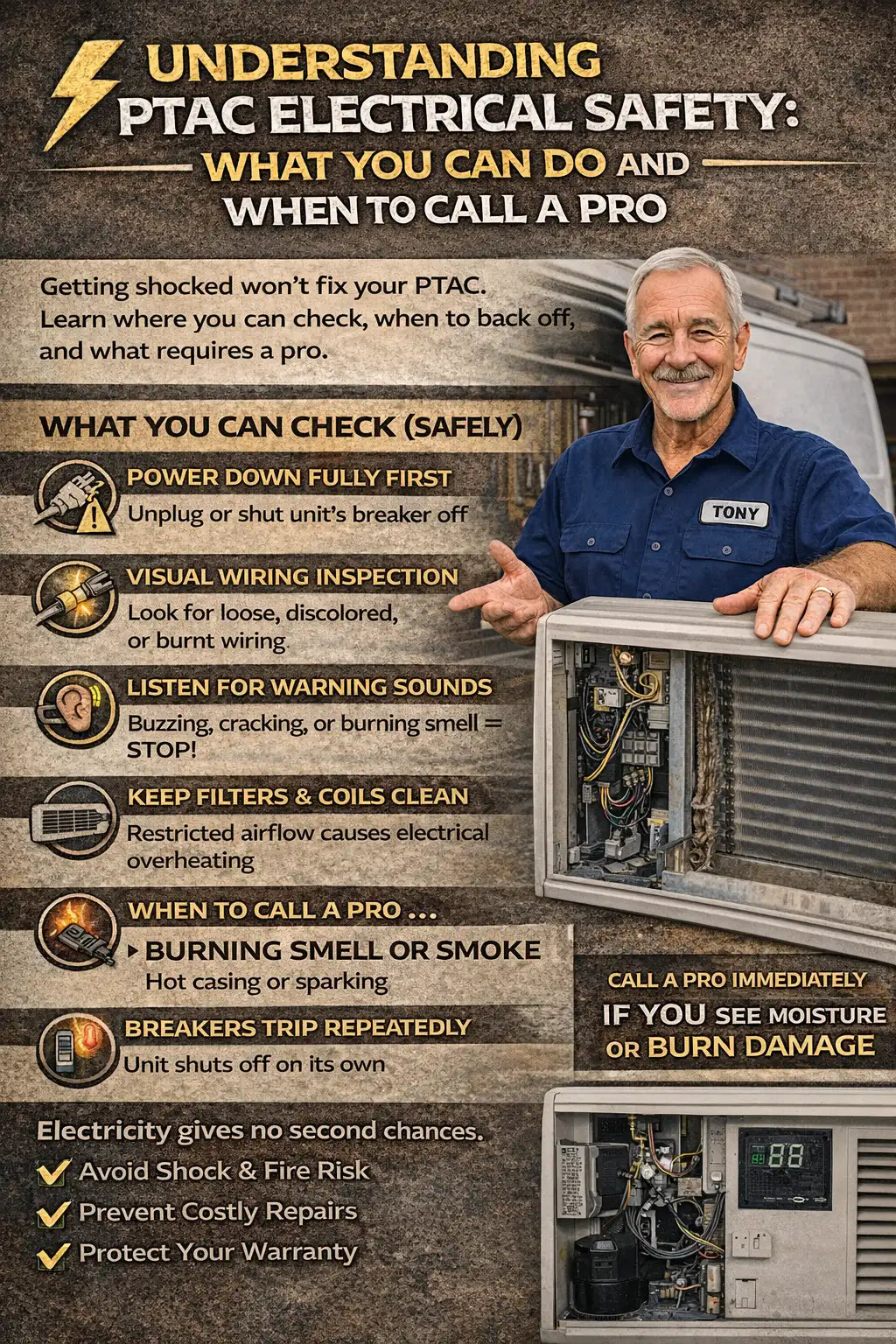

Electricity is the one PTAC topic where confidence can turn into costly mistakes—fast.

I’ve seen burned terminals from “quick fixes,” melted insulation from ignored warning signs, and control boards fried because someone thought resetting a breaker solved the problem. Here’s the straight talk:

PTAC electrical systems are safe when respected—and unforgiving when guessed at.

This guide shows you exactly what’s safe for owners to inspect and maintain, what crosses the line, and how to spot trouble before it becomes dangerous.

Amana J-Series PTAC Model 17,000 BTU PTAC Unit with 5 kW Electric Heat

🧠 How PTAC Electrical Systems Are Different

PTACs pack a lot into a small box:

-

High-voltage power (often 208/230V)

-

Control boards and sensors

-

Motors (fan/blower)

-

Electric heat elements (on heat-strip models)

-

Tight clearances with airflow and moisture nearby

That combo means small electrical problems escalate quickly if ignored.

🔌 Electrical Safety Rule #1: Power Down Properly

Before any inspection—kill the power.

What “Power Off” Actually Means

-

Turn the unit off at the controls

-

Unplug the unit or shut off the dedicated breaker

-

Confirm the display is dark and the fan is silent

Never rely on the wall control alone. If the breaker is on, voltage can still be present.

🧰 What Owners CAN Safely Do (And Should)

These checks are visual and non-invasive. No tools beyond a flashlight and screwdriver.

👀 Visual Wiring Inspection (5 Minutes)

What to look for:

-

Loose connectors

-

Discolored or melted insulation

-

Burn marks near terminals

-

Wires rubbing against sharp metal

What it tells you:

Heat and vibration loosen connections over time. Early discoloration is a warning—catch it now.

If you see blackened plastic or smell burnt insulation, stop and call a pro.

🔊 Listen for Electrical Warning Sounds

Electrical problems announce themselves.

Red-flag sounds:

-

Buzzing or humming that wasn’t there before

-

Clicking during startup

-

Crackling near the control area

These often point to failing relays, loose terminals, or stressed components.

🌬️ Airflow Checks Protect Electrical Parts

Poor airflow causes electrical overheating—especially with electric heat.

Owner checks:

-

Clean or replace filters regularly

-

Keep intake and discharge vents clear

-

Don’t block airflow with furniture or curtains

Restricted airflow makes motors and heat strips run hotter—and fail sooner.

🔄 Safe Reset Practices (When Appropriate)

A reset is acceptable only if it’s infrequent and unexplained.

Safe reset steps:

-

Power off at the breaker

-

Wait 5 minutes

-

Restore power and test

If the breaker trips again:

That’s not a reset issue—it’s a fault.

🔥 Electric Heat Models: Extra Caution Required

PTACs with electric heat strips demand respect.

Why Electric Heat Raises the Stakes

-

High current draw

-

Immediate heat generation

-

Sensitive safety limits

Owner-safe checks:

-

Visual inspection for dust buildup

-

Confirm fan runs immediately with heat

-

Stop using heat if airflow feels weak

The U.S. Department of Energy stresses airflow and cleanliness for electric heating safety

https://www.energy.gov/energysaver/energy-saver

🚫 What Owners Should NEVER Do

This is where most damage happens.

❌ Don’t Attempt to:

-

Tighten live electrical connections

-

Replace capacitors or relays

-

Bypass safety switches

-

Modify wiring

-

Test voltage without training

Even a small mistake can:

-

Damage control boards

-

Void warranties

-

Create shock or fire risk

🚨 Clear Signs It’s Time to Call a Pro

If you see any of the following, stop DIY work immediately.

🔥 Heat & Smell Warnings

-

Burning or electrical odor

-

Hot-to-the-touch casing

-

Smoke or visible sparking

⚠️ Power & Control Issues

-

Breaker trips repeatedly

-

Unit shuts down unexpectedly

-

Display flickers or goes blank

-

Heat works but fan doesn’t (or vice versa)

💥 Physical Damage

-

Melted wire insulation

-

Corroded terminals

-

Water near electrical components

ENERGY STAR notes electrical faults as a common cause of HVAC failure when neglected

https://www.energystar.gov/newhomes/features-benefits/heating-cooling

🧯 Moisture + Electricity: The Silent Risk

PTACs handle condensation by design—but moisture must stay where it belongs.

Owner checks:

-

No standing water near electrical sections

-

Drain pan clear and clean

-

No dripping onto wiring

The CDC confirms moisture increases mold and corrosion risks

https://www.cdc.gov/mold-health/about/index.html

📅 Electrical Safety as Part of Routine Maintenance

You don’t need constant checks—just consistent ones.

Monthly

-

Listen for new sounds

-

Check airflow strength

-

Note any unusual smells

Seasonal (Spring/Fall)

-

Visual wiring inspection

-

Heat or cool mode test

-

Drain and moisture check

Consistency prevents surprises.

🛡️ Warranty & Liability: Why Electrical DIY Has Limits

Most manufacturers expect:

-

No owner modifications

-

Licensed service for electrical repairs

-

Evidence of proper maintenance

Unauthorized electrical work can:

-

Void warranties

-

Create insurance issues

-

Shift liability to the owner

Amana and other manufacturers design PTACs for service—not electrical experimentation

https://www.amana-hac.com

🧠 Tony’s Final Word on PTAC Electrical Safety

Here’s the mindset that keeps owners safe:

Inspect freely. Clean confidently. Repair cautiously.

If you’re looking, listening, and maintaining airflow, you’re doing your part.

If you’re tempted to “just tighten one thing,” that’s the line—step back and call a pro.

Electricity doesn’t give second chances.

Respect it, and your PTAC will run safely for years.

Buy this on Amazon at: https://amzn.to/434DIng

In the next topic we will know more about: Troubleshooting Heating Elements: Signs Your PTAC Heat Isn’t Working Right