Nothing exposes a PTAC problem faster than the first cold night of the season.

Cooling issues usually creep in gradually. Heating failures announce themselves immediately—cold air when you expect warmth, breakers tripping, odd smells, or a unit that runs but never heats.

Amana J-Series PTAC Model 17,000 BTU PTAC Unit with 5 kW Electric Heat

After years of diagnosing PTAC heat complaints, here’s the reality:

Most PTAC heating problems aren’t sudden failures—they’re warning signs that went unnoticed during warmer months.

This guide helps you recognize early symptoms, perform safe owner-level checks, and know exactly when to stop and call a professional.

🧠 How PTAC Heating Works (Quick Context)

Most PTACs use electric resistance heat, not heat pumps.

That means:

-

Power flows through heating elements

-

Elements warm instantly

-

Airflow carries heat into the room

There’s no combustion, no flame—but high electrical demand and airflow sensitivity.

When heat isn’t working, it’s usually one of three things:

-

Power issue

-

Airflow problem

-

Failing heating element or safety control

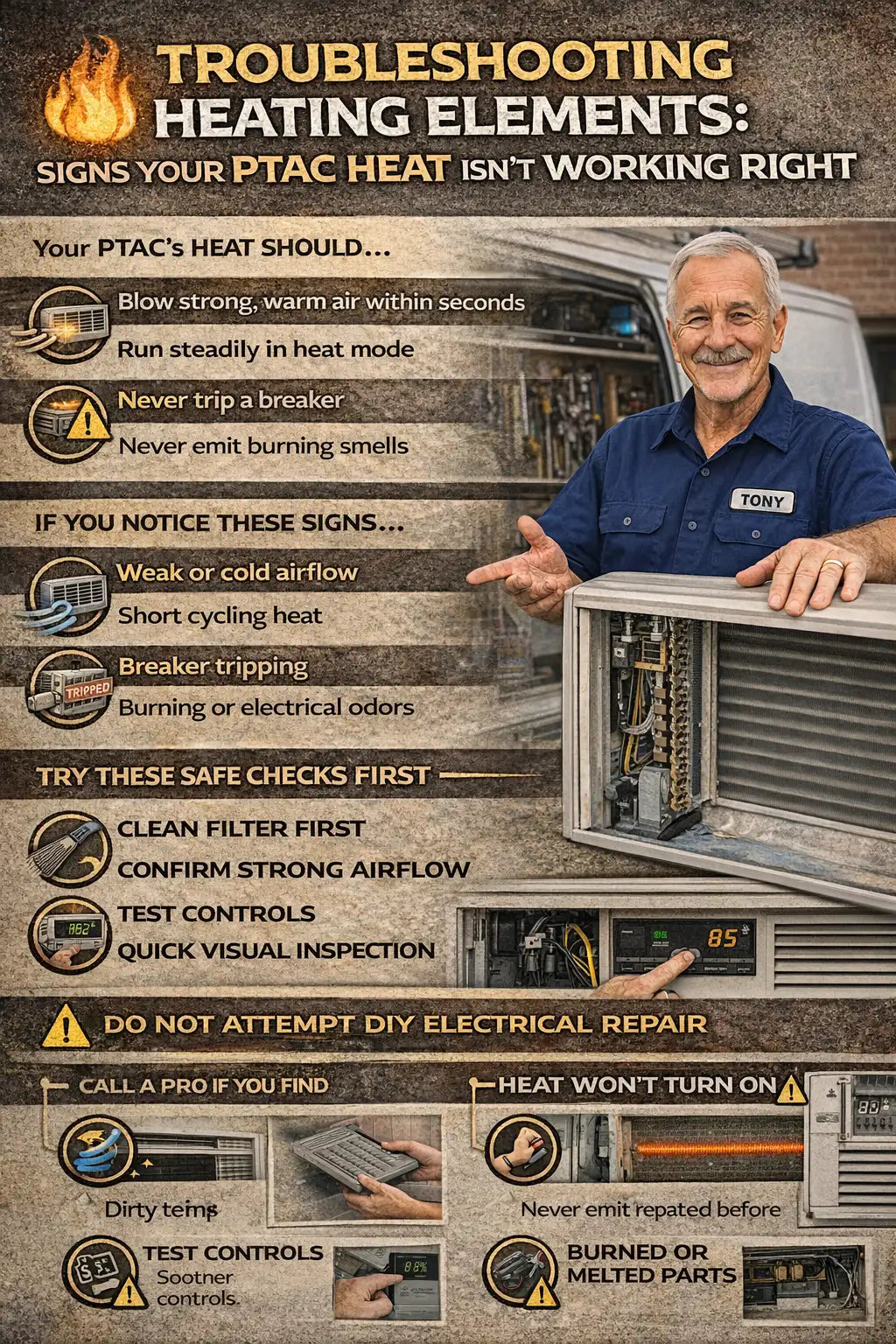

❄️ Early Warning Signs Your PTAC Heat Isn’t Right

Catching problems early saves money and avoids emergency calls.

🌬️ Warm Air Is Weak or Lukewarm

What it feels like:

-

Air blows, but room doesn’t warm

-

Takes far longer than usual to heat

Likely causes:

-

Dirty filter restricting airflow

-

Dust buildup on heating elements

-

Partial element failure

Airflow is critical—electric heat depends on it.

🔁 Heat Turns On and Off Rapidly (Short Cycling)

What you’ll notice:

-

Heat starts, stops, restarts frequently

-

Room never stabilizes

Possible reasons:

-

Overheating due to restricted airflow

-

Faulty temperature sensor

-

Safety limit switch cutting power

Short cycling stresses components and shortens lifespan.

⚡ Breaker Trips When Heat Runs

This is one of the clearest red flags.

If the breaker trips:

-

Immediately stop using heat

-

Do NOT keep resetting the breaker

Possible causes:

-

Failing heating element

-

Loose electrical connection

-

Overcurrent condition

ENERGY STAR identifies electrical faults as a common HVAC failure source

https://www.energystar.gov/saveathome/heating-cooling

Repeated trips are not “normal.”

👃 Burning or Electrical Smells

Not all smells are equal.

Normal (briefly):

-

Light dusty smell at first seasonal startup

Not normal:

-

Sharp electrical odor

-

Plastic or chemical smell

-

Smell that persists beyond a few minutes

If it smells wrong—power down immediately.

🔊 Unusual Noises During Heating Mode

Listen carefully when heat engages.

Concerning sounds:

-

Buzzing or humming

-

Clicking or popping from the unit

-

Fan running without warm air

These often point to electrical or element-related issues, not airflow alone.

🧰 Safe Owner-Level Checks (Before Calling a Pro)

You don’t need tools—just awareness.

🧼 Step 1: Check the Filter First (5 Minutes)

A dirty filter is the #1 cause of PTAC heating complaints.

What to do:

-

Remove and inspect the filter

-

Clean or replace if dirty

-

Ensure it’s fully dry before reinstalling

Restricted airflow causes elements to overheat and shut down.

The U.S. Department of Energy stresses airflow importance for electric heating safety

https://www.energy.gov/energysaver/energy-saver

🌬️ Step 2: Confirm Strong Airflow

With the filter clean:

-

Turn heat mode on

-

Feel airflow at the discharge

Weak airflow = stop troubleshooting

That’s an airflow or motor issue, not just heat.

🔄 Step 3: Test Thermostat & Controls

Check:

-

Temperature set above room temp

-

Unit actually switches into heat mode

-

Fan starts immediately with heat

If controls don’t respond consistently, the issue may be electronic—not the heating element itself.

👀 Step 4: Visual Inspection (Power Off)

With power off:

-

Remove front panel

-

Look for heavy dust near heat section

-

Check for obvious discoloration or debris

Do not touch heating elements.

Visual only.

🚫 What Owners Should NEVER Do

This is where damage happens.

❌ Do not:

-

Test continuity or voltage

-

Bypass safety switches

-

Replace heating elements

-

Tighten electrical connections live

-

Ignore repeated breaker trips

Heating elements draw high current. DIY electrical work here is unsafe.

🚨 Clear Signs the Heating Element Is Failing

These symptoms almost always mean professional service is required.

🔥 Heat Never Comes On (But Fan Runs)

Common causes:

-

Burned-out heating element

-

Failed relay or control board

-

Safety limit lockout

⚠️ Heat Cuts Out After a Few Minutes

Usually caused by:

-

Overheating due to airflow restriction

-

Weak or failing element

-

Faulty limit switch

The CDC notes overheating and moisture can accelerate electrical degradation

https://www.cdc.gov/mold-health/about/index.html

💥 Visible Damage or Melted Components

If you see:

-

Burn marks

-

Melted insulation

-

Corroded terminals

Stop immediately. Continued use risks fire or major damage.

🧯 Moisture & Heating Problems: The Hidden Connection

PTACs manage moisture during cooling—but leftover moisture causes problems in heating season.

Moisture-related issues include:

-

Corrosion on heating terminals

-

Faulty electrical contacts

-

Odors during heat operation

EPA guidance stresses moisture control for HVAC safety and air quality

https://www.epa.gov/indoor-air-quality-iaq

Dry, clean internals matter as much as clean filters.

🛡️ Warranty & Safety Considerations

Manufacturers expect:

-

Proper airflow maintenance

-

No owner-performed electrical repairs

-

Licensed service for heating element replacement

Unauthorized repairs can:

-

Void warranties

-

Create insurance liability

-

Lead to repeat failures

Amana and similar manufacturers design PTAC heat systems for professional service

https://www.amana-hac.com

🧠 Tony’s Diagnostic Shortcut (Real-World Rule)

Here’s a simple way I teach new techs:

If airflow is strong and power is stable—but heat is weak or absent—the element or controls are at fault.

And that’s where DIY ends.

✅ Preventing Heating Problems Before They Start

Most heating failures are preventable.

Best Practices:

-

Clean filters monthly during heating season

-

Inspect PTAC internals before winter

-

Run heat briefly in fall to catch issues early

-

Never ignore smells or breaker trips

Small habits prevent big repairs.

🧠 Tony’s Final Word on PTAC Heating Issues

Electric heat doesn’t fail quietly—it warns you.

Cold air, strange smells, tripping breakers, and cycling heat are not quirks—they’re signals.

Listen early. Check what’s safe.

And when the signs point past airflow or filters, call a pro without hesitation.

That’s not giving up—it’s smart ownership.

Buy this on Amazon at: https://amzn.to/434DIng

In the next topic we will know more about: Fan & Blower Maintenance: Keeping Your Unit Quiet and Efficient