By Mark — Your HVAC Friend in the Field

If your HVAC system was a human body, the line set would be its arteries—circulating refrigerant between the indoor evaporator coil and the outdoor condenser. Without it, nothing gets cooled or heated.

The problem is, many homeowners don’t even know what a line set is until they face a costly replacement. I’ve seen people replace an outdoor unit but keep an old, leaking line set—only to have their new system underperform or fail within months.

In this guide, we’ll cover:

-

The anatomy of a line set

-

Correct sizing for efficiency

-

Why insulation matters

-

Replacement signs to watch for

-

Maintenance tips that extend life

🧩 1. What Is a Line Set?

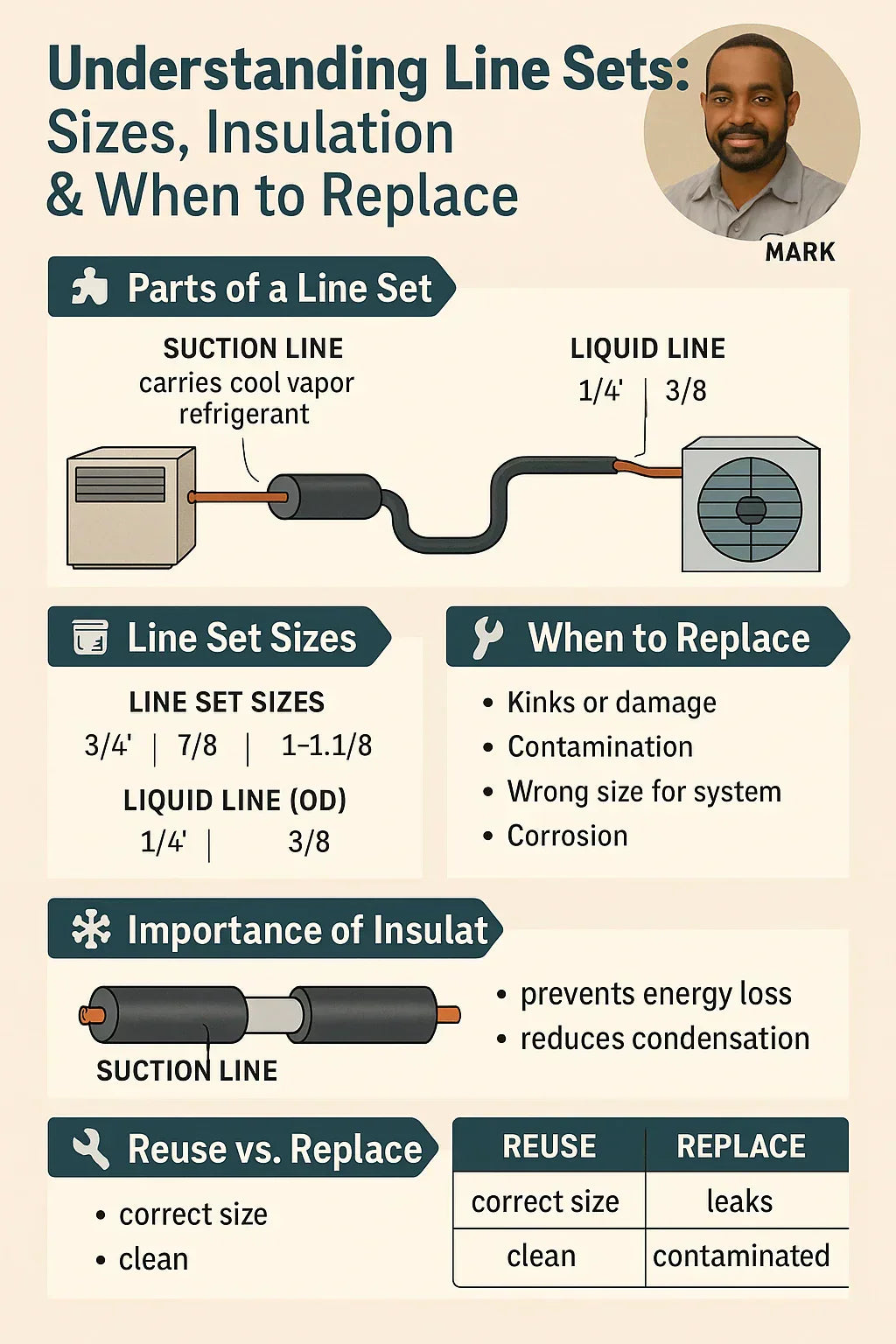

A line set is a pair of copper tubes that transport refrigerant between the indoor and outdoor units of an air conditioning or heat pump system.

The two lines:

-

Suction line (larger) — Carries cool vapor refrigerant from the evaporator coil back to the compressor.

-

Liquid line (smaller) — Carries warm liquid refrigerant from the condenser to the evaporator coil.

Each line has a specific diameter, insulation needs, and role in system efficiency.

Mark’s Tip: If either line is damaged or improperly sized, your whole system suffers—cooling capacity drops, energy bills rise, and the compressor can fail early.

(Carrier)

📏 2. Line Set Sizes — Why They Matter

The size (diameter) of your line set must match your system’s capacity, typically measured in tons.

Typical sizes:

-

Suction line: 3/4", 7/8", 1-1/8" (OD)

-

Liquid line: 1/4", 3/8" (OD)

Sizing factors:

-

Tonnage of system — Higher capacity requires larger suction line diameter.

-

Length of run — Longer runs may require upsizing to maintain efficiency.

-

Refrigerant type — R-410A and R-22 have different flow properties.

Example: A 3-ton R-410A system with a 25-ft run might use a 3/4" suction line and 3/8" liquid line, but a 75-ft run may need an upsized suction line.

(RSES)

🧊 3. The Role of Insulation

The suction line should be insulated to:

-

Prevent condensation from forming on the outside (avoiding water damage)

-

Minimize heat gain so refrigerant stays cool for maximum efficiency

Insulation types:

-

Rubber insulation — Flexible, durable, UV resistant

-

Foam insulation — Lightweight, less durable in sun exposure

Pro Tip: Outdoor insulation should be UV-protected to prevent cracking. Unprotected foam breaks down quickly in sunlight, leading to energy loss and moisture problems.

🧪 4. Pre-Charged vs. Traditional Line Sets

-

Pre-Charged — Already filled with refrigerant, used in DIY or quick-install systems (e.g., ductless mini-splits). Less labor but not reusable once cut.

-

Traditional — Empty copper lines that are vacuumed and charged by a technician during installation. Reusable in some cases if clean and undamaged.

Mark’s Opinion: Pre-charged is convenient for small jobs or DIY mini-splits, but for full central systems, traditional gives more flexibility and is easier to service.

🔍 5. Signs It’s Time to Replace Your Line Set

-

Visible kinks or crushing — Restricts refrigerant flow.

-

Oil stains — Indicates refrigerant leaks (oil travels with refrigerant).

-

Corrosion — Common in coastal or high-humidity environments.

-

Contamination — Old lines with sludge, acid, or debris from a burned-out compressor.

-

Wrong size for new equipment — Replacing a 2-ton with a 4-ton system may require larger lines.

(ACCA)

🛠 6. Reuse vs. Replace

You can reuse a line set if:

-

It’s the correct size for your new system

-

It’s clean, pressure-tested, and leak-free

-

The insulation is intact or can be replaced

Replace if:

-

There’s contamination or damage

-

The sizing is wrong for your new system

-

The cost to clean exceeds the cost to replace

(ASHRAE)

🧼 7. How to Maintain Your Line Set

-

Inspect insulation annually

-

Check for kinks or damage after landscaping or renovations

-

Make sure outdoor portions are protected from direct sun and physical impacts

-

Ensure line set is securely fastened and not rubbing against sharp edges

🏠 8. When to Call a Pro

Line set work usually involves refrigerant handling, which by U.S. law requires EPA Section 608 certification. Even if you’re handy, replacing a line set means cutting, brazing, vacuuming, and recharging—leave that to licensed techs unless you have proper training.

(EPA)

💡 9. Mark’s Quick Reference Chart

| System Size (Tons) | Run Length | Suction Line OD | Liquid Line OD | Notes |

|---|---|---|---|---|

| 1.5–2.0 | ≤25 ft | 3/4" | 3/8" | Std residential |

| 3.0 | ≤25 ft | 3/4" | 3/8" | Upsize if >50 ft |

| 4.0 | ≤25 ft | 7/8" | 3/8" | Check refrigerant type |

| 5.0 | ≤25 ft | 7/8"–1-1/8" | 3/8" | Longer runs = larger suction |

📌 10. Key Takeaways

-

Size matters — Wrong line size hurts efficiency and shortens compressor life.

-

Insulation protects performance — Replace worn or sun-damaged insulation immediately.

-

Know when to replace — Contamination, damage, or sizing mismatch = time for new.

-

Leave refrigerant handling to pros — Safety and legal requirements apply.

In the next topic we will read more about: Condensate Pumps 101: When You Need One and How to Install It